High precision technical parts injection.

Precision Engineering &Material Selection to create detailed models and simulations that adhere to best practices and application.

High precision technical parts injection.

Plastic Injection Molding stands as a cornerstone of Imtec's comprehensive suite of services, embodying our commitment to precision, efficiency, and innovation in the manufacturing industry.

Precision Engineering &Material Selection to create detailed models and simulations that adhere to best practices and application.

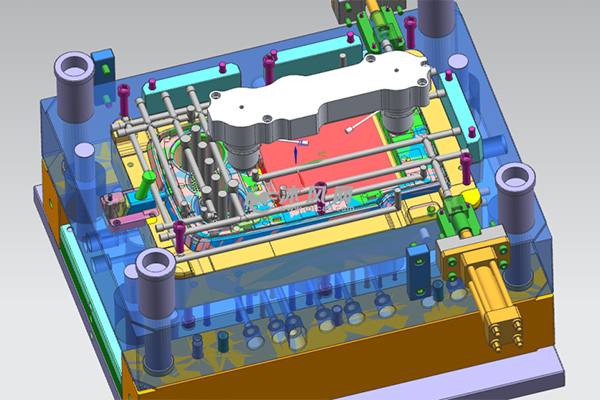

High-Precision Tools & Mold Flow Analysis to ensure accurate and consistent replication of the Technical Parts Injection Moulding design

Precise Control Systems &Process Consistency to maintain process parameters within tight tolerances to produce parts of uniform quality.

Scientific Molding & Quality Control Measures to establish a robust and repeatable injection molding process

Comprehensive Testing & International Standards Compliance to ensure they meet the international quality and safety standards

Expertise & Continuous Improvement to improve product quality and process efficiency.

High Precision Injection Molding Service.

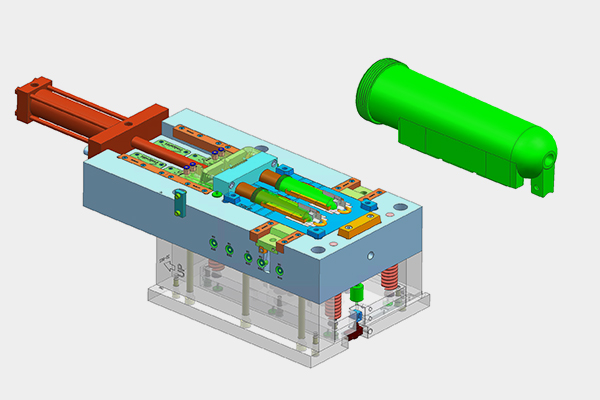

Mechnical Part

Mechnical Part

Injection Mould for Mechanical Parts: Precision Engineering for Performance The Injection Mould for Mechanical Parts is a critica...

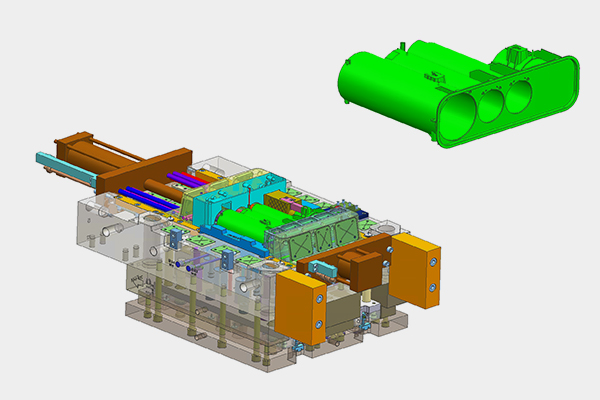

Auto Spare Parts

Auto Spare Parts

Injection Mould for Auto Parts: Precision and Performance The injection mould for auto parts is an essential tool for manufacturi...

Shower Seat

Shower Seat

Injection Mould for Shower Seat: Quality and Innovation Our Injection Mould for Shower Seat is a perfect blend of functionality, ...

Plastic Grab Bar

Plastic Grab Bar

Injection Mould for Plastic Grab Bar: Strength, Safety, and Precision The injection mould for plastic grab bar is designed to pro...

Injection molding, compression molding, blow molding, and extrusion each have distinct advantages, costs, and design constraints. Choosing the right process dep....

Key Takeaways Topic Practical Insight Surface finish Determined by mold preparation, not PP alone Mold material Hardened steels suit high-volume PP Pr....

Acrylic (PMMA) injection molding aims to produce high-clarity, high-gloss parts while minimizing internal stress.PMMA is highly transparent but brittle, and it ....

At Imtec, we are a leading provider of High Precision Injection Molding Services in China, specializing in the production of complex and demanding technical parts.

High-precision molding: We specialize in producing parts with tight tolerances, intricate features, and demanding surface finishes.

Micro-molding: We can produce miniature parts with exceptional precision and detail.

Two-shot molding: We can mold parts with multiple materials or colors in a single process.

Overmolding: We can overmold secondary materials onto existing parts to enhance functionality or aesthetics.

Gas-assisted injection molding: We can produce hollow parts with improved strength and reduced weight.

Cost-Effectiveness: China's competitive labor costs and efficient manufacturing processes can significantly reduce production costs compared to many Western countries.

Skilled Workforce: China boasts a large pool of skilled engineers, technicians, and mold makers with expertise in various aspects of injection molding.

Advanced Manufacturing Infrastructure: The country possesses a robust manufacturing infrastructure with access to state-of-the-art equipment, technologies, and materials.

Strong Supply Chain: China has a well-established supply chain for raw materials, components, and other resources required for injection molding.

Rapid Prototyping and Tooling: Many Chinese manufacturers offer rapid prototyping services and in-house tooling capabilities, accelerating product development cycles.

Automotive

Medical

Electronics

Aerospace

Telecommunications

Consumer Goods

Automotive Components: Engine parts, interior trims, exterior panels, and more.

Medical Devices: Surgical instruments, implants, diagnostic equipment, and pharmaceutical packaging.

Electronics: Connectors, enclosures, housings, and internal components.

Consumer Goods: Toys, household appliances, consumer electronics, and sporting goods.

Industrial Parts: Machinery components, automotive parts, and other industrial applications.