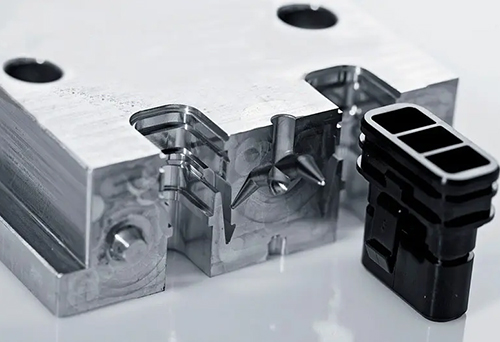

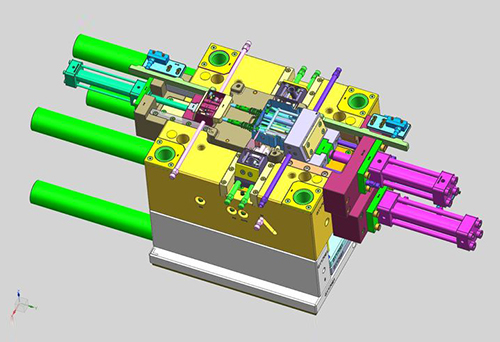

Starting from a 3D part, we design and manufacture molds to the highest international standards (DME/HASCO/MISUMI )

Ensure the the projects stay on track and the customers can be fully aware of the current status.

Starting from a 3D part, we design and manufacture molds to the highest international standards (DME/HASCO/MISUMI )

Ensure the the projects stay on track and the customers can be fully aware of the current status.

Traceable supervision in ERP system to ensure on time delivery

Ensure production-ready mold, saving the customers time and money

Maintain effective communications throughout the entire process to lend support for the projects.

Improve the design to manufacture the product at the lowest cost, shortest time and highest quality,reduce the risk.

More than 30 years offering the most advanced technology of Injection Molding to our customers.

Plastic insert moulding is an effective alternative to assemblies manufactured using soldering, adhesives or fasteners.

We can develop different solutions with different alternatives based on the customers' demand

Injection molding, compression molding, blow molding, and extrusion each have distinct advantages, costs, and design constraints. Choosing the right process depends on part complex....

Key Takeaways Topic Practical Insight Surface finish Determined by mold preparation, not PP alone Mold material Hardened steels suit high-volume PP Processing Shrinkage m....

Acrylic (PMMA) injection molding aims to produce high-clarity, high-gloss parts while minimizing internal stress.PMMA is highly transparent but brittle, and it is sensitive to stre....

Quick Summary for Professionals Injection mold repair is the specialized process of restoring damaged tooling to its original engineering specifications to ensure part quality and....

High Quality & Reliability: These brands are known for producing high-quality, reliable components that contribute to increased mold durability and reduced downtime.

Improved Performance: Utilizing their components can lead to enhanced mold performance, including faster cycle times, increased production rates, and better part quality.

Standardization: Many of their components are standardized, making assembly, maintenance, and repairs easier and more efficient.

Wide Range of Options: DME, HASCO, and MISUMI offer a vast selection of components, providing flexibility and customization options for your specific mold design needs.

The European Mold Design Philosophy emphasizes precision, efficiency, and long-term durability. It focuses on meticulous design and rigorous testing to ensure optimal mold performance and minimize production issues.

Benefits to customers include:

Increased mold lifespan and reduced maintenance costs.

Improved part quality and consistency.

Enhanced production efficiency and reduced downtime.

We work with a wide range of plastics and resins, including:

Engineering plastics (e.g., nylon, polycarbonate, PEEK)

Thermoplastics (e.g., ABS, polypropylene, polyethylene)

Thermosets (e.g., epoxy, polyester)

And more.

We serve a variety of industries, including:

Automotive

Electronics

Medical

Consumer goods

And others.

Our approach involves:

3D modeling and simulation using advanced CAD/CAM software.

Designing for manufacturability to optimize production efficiency.

Close collaboration with customers to understand their specific requirements.

Rigorous quality control throughout the entire manufacturing process.

Utilizing state-of-the-art equipment and adhering to industry standards.

You can contact us directly through our website or by phone. We will gather the necessary information about your project, such as part design, material requirements, and production volume. We will then provide you with a detailed quote and discuss your project in more detail.

Yes, we typically offer warranties on our injection molds. Please contact us for specific details on our warranty policies.