3D Printing in the Automotive Industry: Revolutionizing Car Manufacturing

Introduction: The Gear Shift of Manufacturing

Have you ever stopped to think about what it takes to build a modern car? It's a symphony of stamping, welding, casting, and machining—processes that have been the industry standard for over a century. They're reliable, but they're also slow, expensive to set up, and inherently restrictive when it comes to design.

But the automotive world is at a crucial inflection point. Faced with relentless demands for lighter vehicles, faster development cycles, and hyper-customized designs, traditional manufacturing methods are starting to sputter.

Enter 3D Printing, or as the engineers call it, Additive Manufacturing (AM).

This isn't just about printing plastic trinkets anymore. AM is transforming from a neat prototyping trick into a formidable production technology that's actively shaping the future of mobility. In the demanding, high-stakes world of car manufacturing, 3D printing is no longer a "nice-to-have" option—it's fast becoming a must-have advantage.

This article will explore how 3D printing is helping carmakers redefine everything, from the simple jig on the factory floor to the complex metal part deep inside your engine, revealing the true power behind this manufacturing revolution.

What is 3D Printing? (A Quick Primer)

Before we talk about how 3D printing is building the next BMW or Ford, let's make sure we're all on the same page about the technology itself.

The Fundamental Difference: Additive vs. Subtractive

Think of traditional car manufacturing (machining, milling) as Subtractive Manufacturing. You start with a big block of material (a billet) and cut, drill, or carve away everything youdon'twant until you're left with the final part. It's effective, but it creates a massive amount of waste.

3D Printing, conversely, is Additive Manufacturing. It's literally the opposite. You start with nothing and build the part up, layer by microscopic layer, exactly where the material is needed, based on a digital 3D model. This "only using what you need" approach is the source of many of its revolutionary benefits, especially in cost and material efficiency.

Common 3D Printing Processes Used in Automotive

The term "3D printing" covers a family of technologies, and the automotive industry uses several key players, depending on whether they need a quick plastic prototype or a structural metal component:

| Process Acronym | Full Name | Material Focus | How It Works (The Gist) | Best For Automotive... |

| FDM | Fused Deposition Modeling | Thermoplastics (Polymers) | Melts and extrudes a plastic filament, building layer by layer, like a very precise hot glue gun. | Quick, low-cost Prototypes and simple Jigs/Fixtures. |

| SLA | Stereolithography | Photopolymer Resins | Uses a laser to cure liquid resin into a solid object. Known for high detail and smooth surfaces. | Highly accurate Prototyping, intricate Design Models. |

| SLS | Selective Laser Sintering | Nylon Powders (Polymers) | Uses a high-powered laser to fuse fine powder particles together, layer by layer. Excellent strength. | Functional Prototypes and End-use Parts (e.g., HVAC ducts, interior trim). |

| MJF | Multi Jet Fusion (HP) | Nylon Powders (Polymers) | Uses an agent-jetting system combined with a heating lamp to rapidly fuse layers of powder. Known for speed and volume. | Tooling, Low-to-Mid Volume End-Use Parts (e.g., custom vents, fluid reservoirs). |

| DMLS | Direct Metal Laser Sintering | Metal Powders (Aluminum, Steel, Titanium) | Similar to SLS, but uses a powerful laser to fully melt and fuse fine metal powders. | Structural Components, Engine Parts, High-Performance Tooling. |

Materials: What Are We Printing With?

The materials available today are what truly opened the door for 3D printing in serious automotive applications.

-

Polymers (Plastics): Beyond basic plastic, we're talking about industrial-grade, flame-retardant nylons, polycarbonates, and specialized resins that can withstand the heat, vibration, and UV exposure required in a vehicle.

-

Composites: These are polymers reinforced with fibers, most commonly carbon fiber. These materials are crucial for achieving lightweighting goals, offering the strength of metals at a fraction of the weight—perfect for electric vehicle battery enclosures and aerodynamic spoilers.

-

Metals: The game-changer. Using technologies like DMLS, manufacturers can print aluminum alloys (ideal for heat dissipation), stainless steel, and titanium for mission-critical parts like exhaust components, specialized brackets, or even certain engine elements.

With this foundation set, we can now appreciatewhycar companies are investing heavily in this technology—it's not just about speed, it's about the material possibilities and the design freedom that metal and composite AM allows.

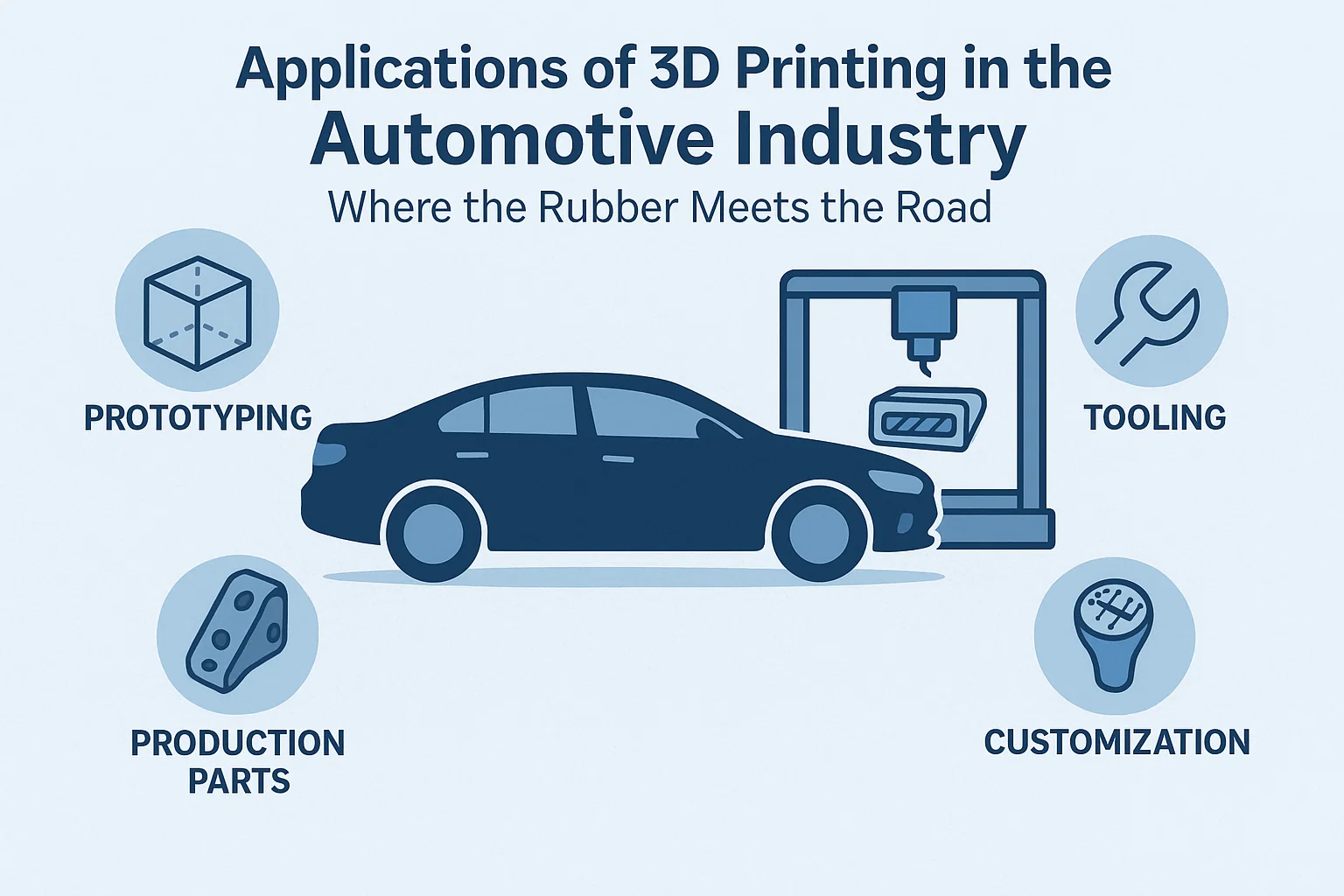

Applications of 3D Printing in the Automotive Industry: Where the Rubber Meets the Road

The true power of 3D printing isn’t just in its ability to build things layer by layer, but in its sheer versatility across the entire product lifecycle—from the earliest sketch to the final spare part, decades later. For the automotive industry, AM is a multi-tool that addresses five core areas:

1. Prototyping: Speeding Up the Design Race

This is the OG application, the reason 3D printers first entered automotive R&D labs.

-

Faster and Cost-Effective Prototyping: Imagine a designer creates a new air vent design. Traditionally, creating a physical version required sending the CAD file to a machine shop, setting up molds or tooling, and waiting days or even weeks. With a modern industrial 3D printer (like an SLA or MJF system), that engineer can have a physically accurate, functional prototype on their desk overnight.

-

Rapid Iteration: This acceleration means engineers can testmoredesigns. Instead of just testing two design options for a complex manifold, they can test ten. Flaws are discovered earlier, design iterations are faster, and the time it takes to lock in a final design is dramatically reduced—shaving crucial weeks off the product development cycle.

-

Examples: Automakers regularly print full-scale aesthetic models of dashboards, wind-tunnel-ready aerodynamic components, and even functional, load-bearing parts for early test mules.

2. Tooling: The Secret Efficiency Weapon

While prototypes get the headlines, 3D printed tooling, jigs, and fixtures are the quiet heroes transforming assembly line efficiency. These aren't parts that gointothe car, but rather the custom aids usedto buildthe car.

-

Customization and Ergonomics: The assembly line is full of repetitive, precise tasks. 3D printing allows technicians to quickly create lightweight, custom-fitted tools (like drill guides, alignment jigs, or sensor-mounting fixtures) tailored exactly for a specific car model's contours or even for a specific employee’s hand.

-

Cost and Time Savings: Why spend thousands of dollars and weeks machining a metal check gauge that will only be used for a limited production run? A 3D printed polymer version, often reinforced with carbon fiber (like Nylon 12 CF), can cost a fraction and be printed in a day, leading to huge reductions in overhead and downtime.

3. Production Parts: Moving to End-Use

This is the most exciting frontier. It's the shift from "3D printing a prototype" to "3D printing a part that ships in the car."

-

Low-Volume and Performance Vehicles: For sports cars, hypercars, or electric vehicles with limited production numbers, the cost of traditional tooling is prohibitive. 3D printing offers a way to manufacture highly complex, high-performance parts (like titanium exhaust tips, specialized cooling channels, or complex metal brackets) without investing in multi-million dollar molds.

-

The Power of Part Consolidation: This is a key technical insight. Traditional assemblies might require six different stamped, welded, or cast pieces. 3D printing, especially metal AM (DMLS), allows engineers to design all six functions into one single, geometrically complex part. This reduces assembly time, lowers the part count (and inventory complexity), and often results in a stronger, lighter component.

-

Examples: General Motors now incorporates over a hundred 3D-printed end-use components in new vehicles like the Cadillac Celestiq, ranging from cosmetic trim to structural brackets.

4. Customization and Personalization: The "My Car" Experience

The market is moving away from "mass-produced" and toward "mass-customized." 3D printing is the engine of that shift.

-

Unique Interior Elements: Want your name etched into the dashboard trim, or a specific graphic pattern on your gear shift knob? 3D printing makes it economically feasible. Automakers can offer a catalogue of hundreds of personalized options without stocking large inventories, printing themon demand.

-

Aftermarket and Accessories: Enthusiasts and tuners use 3D printing to create custom air intakes, modified exterior body elements, or mounts for aftermarket gauges—a level of personalization traditional mass production cannot touch.

5. Spare Parts and Repair: Digital Warehousing

For older or low-volume models, spare parts inventory is an economic nightmare. Manufacturers must guess demand, produce extra, and store them for years.

-

On-Demand Digital Inventory: The solution is the digital warehouse. Instead of a physical shelf full of dust-covered parts, automakers store the digital CAD file. When a rare part is needed—say, a specific plastic cap for a 20-year-old classic—they simply download the file and print it on the nearest industrial printer.

-

Preserving Automotive Heritage: This is crucial for classic car restoration. Porsche, for instance, uses 3D printing to supply ultra-rare metal parts for their iconic vintage models, ensuring these vehicles stay on the road without having to recreate expensive, decades-old tooling.

Part III: The Business Imperative—Why Additive Manufacturing is Essential for the Future Car

If the previous section explained the widespread application of 3D printing, the question for every executive and engineer remains: Why endure a strategic shift to adopt it? The answer lies in five powerful, measurable business advantages that are fundamentally reshaping the economics of car production.

1. The Power of Lightweighting and Performance

The pursuit of lower vehicle weight—lightweighting—is not an abstract goal; it is a critical mandate driven by the demand for higher performance and the existential need for greater battery range in Electric Vehicles (EVs). 3D printing offers an unrivaled solution:

-

Generative Design: Unlike traditional manufacturing, which is limited by the constraints of molds and machining, additive manufacturing (AM) can bring designs created by generative design software to life. An engineer inputs the load requirements and spatial constraints, and AI-driven software designs the part using only the minimal material necessary.

-

Complex Internal Structures: This process results in organic, lattice-like geometries—structures that are impossible to cast or machine—that deliver equal or superior strength while reducing part mass by up to 50%.

-

Performance Gains: For EVs, every kilogram saved translates directly into miles of extended range. For high-performance and motorsport vehicles, lighter components mean superior agility, better fuel economy, and a competitive edge on the track. Bugatti, for instance, famously 3D-printed a titanium brake caliper that was nearly half the weight of its aluminum predecessor.

2. Time-to-Market: Accelerated Iteration

In a rapidly changing market where a new EV model can be rendered obsolete in under five years, speed is paramount. 3D printing collapses the traditional product development timeline.

-

Rapid Prototyping: The ability to print a functional, high-fidelity prototype in hours or days, rather than weeks or months required for traditional tooling (molds, dies), is a game-changer. This allows engineers to conduct dozens of design iterations on critical components, from air intakes to interior consoles, leading to a superior final product.

-

Tool-Less Production: By removing the time-intensive and costly step of creating molds and tooling, 3D printing drastically reduces the development cycle. Design changes that once took months of re-tooling can now be implemented overnight by simply updating a digital CAD file.

3. Supply Chain Agility and Digital Inventory

The vulnerabilities of a global, centralized supply chain were painfully exposed during recent crises. Additive manufacturing provides a pathway to greater resilience and a significant reduction in operational costs.

-

On-Demand Manufacturing: Automotive companies can replace physical warehouses of spare parts with a digital inventory. Instead of stocking thousands of legacy or low-volume parts for decades, they store a secure CAD file and print the part at a local facility, or even a dealership, only when a customer needs it.

-

Reduced Inventory Costs: This shift eliminates immense warehousing, shipping, and obsolescence costs. For classic car divisions, this ensures that rare parts can always be reproduced without having to commit to an economically prohibitive production run.

-

Local Production: The technology facilitates decentralized, localized production, insulating manufacturers from geopolitical disruptions and high cross-border shipping costs.

4. Customization as a Core Feature

Mass production has long been the enemy of personalization. 3D printing flips this dynamic, making customization an economical reality, even for high-volume manufacturers.

-

Mass Customization: For luxury brands and special edition vehicles, unique trim pieces, dashboard components, and personalized accessories can be printed on a small scale without incurring the prohibitive costs of custom tooling.

-

Ergonomics and Efficiency: On the factory floor, highly specialized jigs, fixtures, and ergonomic assembly aids can be custom-printed for specific lines or even individual workers, drastically improving manufacturing efficiency and reducing the risk of human error.

5. Part Consolidation and Assembly Simplicity

A traditional assembly often involves dozens of discrete pieces—fasteners, brackets, channels—that must be manufactured separately and assembled with labor and complexity.

-

Integrated Components: Additive manufacturing can consolidate ten or more complex, interlocking parts into a single, cohesive component. This not only makes the part stronger and lighter (by eliminating fasteners) but also dramatically simplifies the assembly process, reducing labor costs and minimizing potential points of failure.

Part IV: The Proof is in the Part—Real-World Case Studies and Production Volume

The strategic advantages of additive manufacturing are no longer theoretical. The most innovative automakers have moved far beyond prototypes, integrating 3D printed components directly into their production lines and high-performance vehicles.

Here are the definitive case studies that validate the industry's shift:

1. The High-Performance Pioneer: Bugatti

Bugatti’s work represents the pinnacle of combining generative design with metal additive manufacturing to solve extreme performance challenges.

-

The Component: An 8-piston monobloc Titanium Brake Caliper (for the Chiron hypercar).

-

The Technology: Selective Laser Melting (SLM) of the high-performance titanium alloy, Ti6Al4V.

-

The Impact: The 3D printed caliper weighs just 2.9 kg, a 40% weight reduction compared to the conventionally manufactured aluminum version (4.9 kg). Critically, it achieved this weight reduction while maintaining a tensile strength of and passing the most rigorous testing, including stops from . This was the largest functional titanium component ever printed for an automotive application at the time of its development.

2. The Volume Leader: The BMW Group

BMW is arguably the most advanced mass-market manufacturer in terms of integrating AM across its entire operation—from R&D to final product and factory floor optimization.

-

The Production Scale: The BMW Group now produces over 400,000 3D printed parts per year across its global production network.

-

End-Use Examples: BMW has integrated printed components into various models, including:

-

Roof Brackets: On vehicles like the BMW i8, custom-printed, load-optimized polymer brackets were used to secure lightweight carbon fiber reinforced plastic (CFRP) roofs.

-

Custom Grippers and Jigs: On the assembly line for its M-series CFRP roofs, BMW uses massive, bionic (organically structured) robot grippers that are lighter than their predecessors. This weight saving allows the automaker to use smaller, more energy-efficient robots, reducing costs and energy consumption.

-

-

The Digital Factory: By establishing its dedicated Additive Manufacturing Campus, BMW is rapidly developing and disseminating the knowledge to print tools, jigs, and fixtures at any of its global plants, achieving localized, on-demand supply chain resilience.

3. The Efficiency Innovator: Ford Motor Company

Ford has strategically leveraged 3D printing to save millions annually, primarily by applying the technology to high-value areas on the factory floor and in the aftermarket.

-

Tooling and Manufacturing Aids: At plants like the Valencia Transmission Plant, Ford's internal 3D printing lab has created a catalog of over 5,000 printable parts, producing tens of thousands of printed manufacturing aids and spare parts annually. These custom tools—such as check gauges, drill guides, and custom clips—significantly improve worker ergonomics and dramatically reduce downtime.

-

The Cost Advantage: When a critical assembly line fixture breaks, traditionally the replacement could take weeks and cost thousands of dollars. By printing the part in-house in hours for a fraction of the cost, Ford maintains unparalleled operational continuity.

-

Aftermarket and Legacy Parts: Like Porsche and other major OEMs, Ford is digitizing its inventory of discontinued spare parts, ensuring that owners of classic or older models can always source a functional, OEM-spec replacement part on demand.

4. The Future Vehicle: General Motors (GM)

GM is showcasing how generative design and 3D printing combine to produce parts that redefine structural integrity and weight reduction.

-

The Component: A Generatively Designed Seat Bracket (produced in collaboration with Autodesk).

-

The Impact: GM's new bracket design consolidated eight different traditional components into a single, complex 3D printed piece. The resulting part was lighter and stronger than the original assembly. This integration of function and structure is the clearest signal that 3D printing is not just a replacement process, but a fundamental redesign philosophy for the entire vehicle.

The Three Pillars of the Additive Future

The integration of 3D printing creates three major paradigm shifts that will define the automotive landscape for the next century:

1. The Mass Customization Imperative

Traditional manufacturing is a model of mass production—tooling is designed for millions of identical parts. Additive manufacturing, however, enables mass customization. For high-end luxury or performance vehicles, this means unique, driver-optimized components (custom steering wheels, seating mounts) can be manufactured on demand. For consumers, it opens the door to personalized trim, badging, and interior elements without incurring exorbitant costs.

2. The Electric Vehicle (EV) Advantage

Electric vehicles benefit disproportionately from weight reduction. The efficiency of an EV is directly tied to its mass. By allowing engineers to create complex, bionic structures and consolidate multiple components into one (as seen with GM), 3D printing is the most effective tool available to reduce vehicle weight, thereby extending battery range and reducing overall material consumption.

3. The Digital Supply Chain and Resilience

The ultimate goal is the digital inventory. Instead of warehousing thousands of physical spare parts for decades, manufacturers can store the digital file (the CAD blueprint). When a part is needed—whether it’s a tool on the assembly line or a replacement component for a 20-year-old vehicle—it can be printed locally, anywhere in the world, in a matter of hours. This shift eliminates warehousing costs, drastically cuts shipping times, and provides unprecedented resilience against global supply chain disruptions.

Final Outlook

The automotive industry is moving toward a highly decentralized, digitally-driven production model. Every part will be subject to the question:Is this component better manufactured subtractively, or additively?

As 3D printing technologies continue to increase in speed, material variety, and scale, the answer will increasingly be the latter. This technology will not just improve cars; it will redefine how and where they are built, ushering in an era of production that is faster, lighter, stronger, and inherently more sustainable.

English

English bahasa Indonesia

bahasa Indonesia