The Bottom Line

If you’re looking for the “too long; didn’t read” version, here’s the reality: 3D Printing is for flirting with ideas; Injection Molding is for committing to them. The choice usually boils down to a single question: How many do you need? * Stick with 3D Printing if you’re making fewer than 500 parts, still tweaking your design, or need a “hail mary” prototype by tomorrow morning. You pay zero upfront for tooling, but you’ll pay a “time tax” for every single unit you produce.

- Pull the trigger on Injection Molding the moment you’re ready to scale past 1,000 units. You’ll have to swallow a massive upfront bill for the mold (think $5,000 to $50,000+), but your per-part cost will plummet from dollars to pennies.

To be honest, the smartest teams don’t actually choose one—they use 3D printing to fail fast and cheap, then switch to molding to win big at retail. This guide breaks down exactly where that “break-even” point lives and how to avoid the expensive mistakes that usually kill a project before it even launches.

Let’s get straight to it. You have a digital file and you need a physical part. Now comes the moment that usually determines whether your project succeeds or becomes a massive headache: How do you actually make it?

Most people think it’s a simple choice between the “new school” (3D Printing) and the “old school” (Injection Molding). But honestly? It’s rarely that black and white anymore.

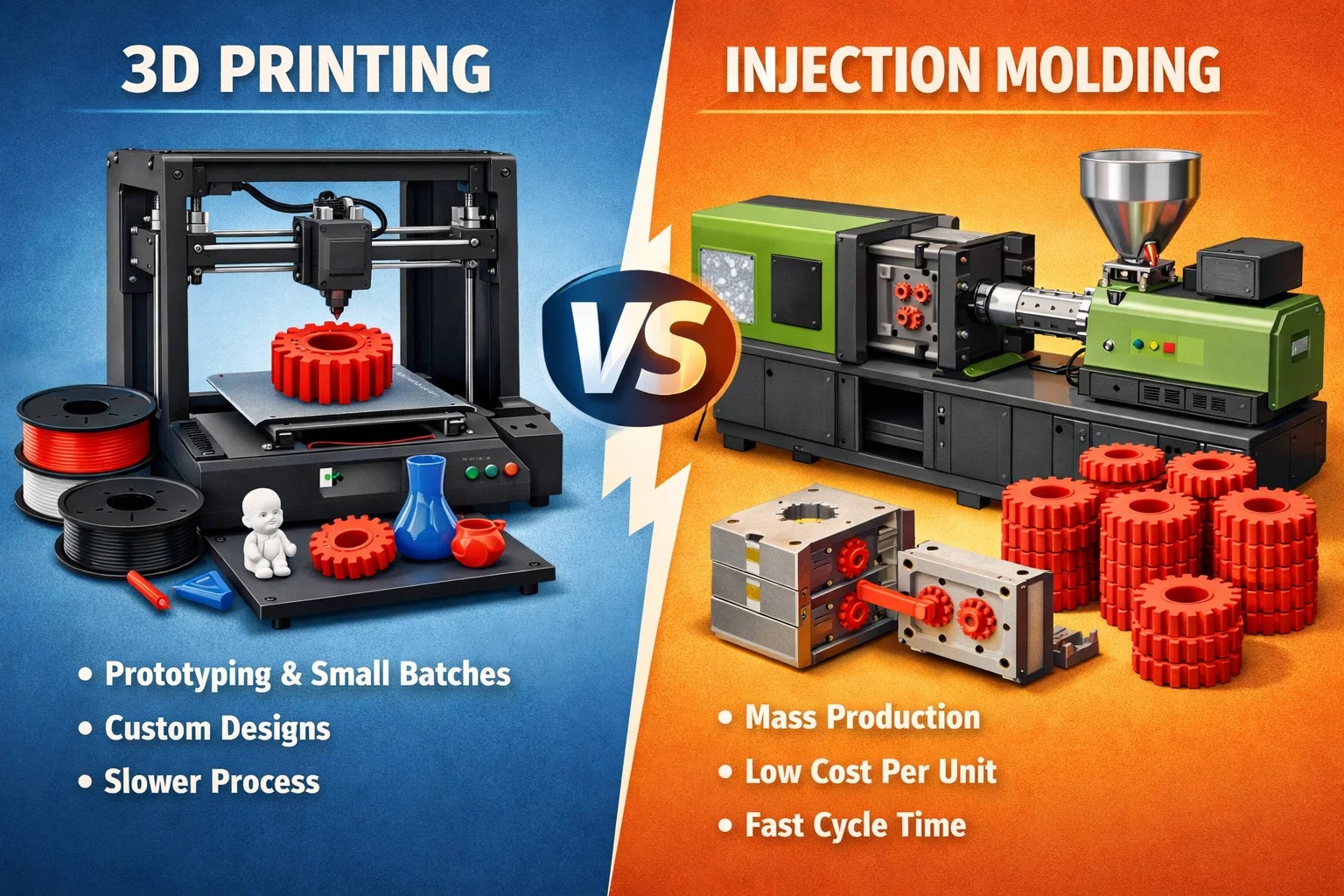

The Real Difference

Forget the textbooks for a second. Here is what’s actually happening:

- 3D Printing is like using a high-tech glue gun to draw your object into existence, layer by layer. No tools, no big setup—just you, a machine, and a digital file. It’s ultimate freedom, until you realize you need a thousand of them by Friday.

- Injection Molding is more violent. You’re slamming molten plastic into a precision-cut steel “cave” at incredible pressure. It’s expensive to start and takes forever to set up, but once that machine starts humming, it’s an unstoppable beast of efficiency.

Why This Isn’t Just “Tech Talk”

I’ve seen plenty of founders get romantic about 3D printing, only to realize their per-unit cost makes their product impossible to sell. On the flip side, I’ve seen engineers drop $30,000 on a steel mold for a product that hasn’t even been market-tested yet. That’s a painful mistake to make.

The “old rules”—where printing was for toys and molding was for “real” manufacturing—are dead. Today, the lines are blurred. Can you print a bridge production run? Usually. Should you mold a prototype? Sometimes.

The Goal

I’m not here to give you a lecture. I want to help you find that “sweet spot”—the exact moment where one process starts saving you money and the other starts burning it. We’re going to look at the grit: the lead times, the mechanical strength, and the cold, hard math of the break-even point.

Ready to see which path actually fits your project? Let’s move.

Should we jump straight into the “What is 3D Printing” section next? I’ll keep it just as sharp.

Let’s look at 3D printing—or what the industry likes to call “Additive Manufacturing.” Honestly, the name tells you everything: you’re starting with zero and adding material only where you need it.

Think of it like building a house brick by brick, except the bricks are microscopic and the “mason” is a laser or a nozzle following a digital map.

The Tech in the Real World

You’ve probably heard of FDM (the one that looks like a robotic glue gun), but that’s just the tip of the iceberg. If you need something that doesn’t look like it was made in a garage, you’re looking at SLA or DLP, which use light to turn liquid resin into solid, smooth-as-glass parts. Then there’s SLS or MJF—the heavy hitters. These use lasers to fuse nylon powder into parts so strong you can actually use them in a car engine or a flight suit.

The Good, The Bad, and The Honest

Why do people love it? Speed and freedom. If you have an idea at 9 AM, you can have a physical part in your hand by dinner. No molds, no “tooling,” and no “you can’t make that shape” from a grumpy machinist. If you need one part or ten, 3D printing is your best friend.

But here’s the catch most people gloss over: It’s slow. Building a part layer by layer takes time—sometimes hours, sometimes days. And let’s talk about the “per-part” cost. While the first part is cheap, the 1,000th part costs exactly the same as the first. There’s no “bulk discount” from the laws of physics here.

Plus, there’s the “grain” issue. Just like wood, printed parts have layers. If you pull against those layers, the part might snap. It’s getting better with new resins and metals, but it’s still something that keeps engineers up at night.

Is it for you?

If you’re still tweaking your design, or if you only need a handful of custom parts that look like they belong in a sci-fi movie, stop looking. You’ve found your winner. But if you’re planning on filling a warehouse? Well, that’s a different conversation entirely.

Want to move on to Injection Molding? We can talk about why it’s such a headache to start, but so beautiful once it’s running.

Now, let’s talk about the heavy hitter: Injection Molding. If 3D printing is a sculptor carefully carving a statue, injection molding is a high-speed stamp. You take a block of steel or aluminum, carve a “negative” cavity of your part into it, and then blast molten plastic into that void at terrifyingly high pressures. Once it cools—which happens in seconds—the mold pops open, drops the part, and resets. Rinse and repeat, thousands of times a day.

The Upfront “Wall”

I’ll be blunt: getting started with injection molding is a slog. You don’t just “press print.” You have to design the mold, which is an engineering feat in itself. You have to think about “draft angles” (so the part doesn’t get stuck) and “gate locations” (where the plastic enters).

Then there’s the bill. A decent steel mold can easily set you back $5,000, $20,000, or even $100,000 before you’ve produced a single usable part. And the wait? Expect to sit on your hands for 4 to 10 weeks while the tool is being machined and polished.

Why Bother?

With all that hassle, why does anyone do it? Because once the “tooling” is done, the math flips in your favor. We’re talking about a per-part cost that drops from dollars to pennies.

It’s not just about the money, though. Injection molded parts are strong. Since the plastic is one continuous, pressurized mass rather than a stack of layers, the structural integrity is world-class. Want a specific texture? A “soft-touch” finish? A specific shade of “Ferrari Red”? Injection molding handles that effortlessly. From the ABS in your LEGO bricks to the medical-grade PEEK in a heart valve, the material library is basically infinite.

The Trade-off

The biggest drawback—besides the cost—is that you’re “locked in.” If you find a mistake in your design after the mold is cut, you’re looking at a very expensive paperweight and a lot of explaining to do to your accountant. It’s a process that rewards those who have done their homework and are ready to go big.

Should we move to the “Key Differences” section? This is where we break down the actual “Break-Even” math to see which one saves your budget.

Let’s get down to the brass tacks: The Decision Matrix. This is where the theoretical stuff ends and your budget begins. Most people get paralyzed here, but it really comes down to a few cold, hard variables.

1. The “Break-Even” Math

This is the big one. With 3D printing, your cost is flat. Whether you make 1 part or 100, you’re paying for the machine time and the material. It’s a straight line.

Injection molding, however, starts with a massive vertical spike (the tooling cost). But as you produce more, that cost gets “diluted.”

The Rule of Thumb: * 1 to 500 units: 3D printing is almost always the winner.

- 500 to 2,000 units: This is the “Gray Zone.” It depends on how complex your part is.

- 2,000+ units: Stop thinking and go with Injection Molding. The pennies you save per part will eventually pay for that expensive mold and then some.

2. Design Flexibility vs. Precision

Think of 3D printing as “Design for Anything.” You want a hollow lattice structure inside a sphere? No problem. 3D printing doesn’t care about complexity.

Injection molding is a different beast. You have to “Design for Manufacturing” (DFM). You need draft angles (slight tapers) so the part can actually slide out of the mold. You have to worry about wall thickness—if one part of your design is too thick, it’ll “sink” or warp as it cools. If you change your mind later? Changing a 3D file takes five minutes; changing a steel mold takes five weeks and a few thousand dollars.

3. Strength and Surface Finish

Let’s be real: if you need a part to look like it came off a retail shelf, injection molding is the gold standard. The surface is smooth, the color is baked in, and the part is “isotropic”—meaning it’s equally strong in every direction.

3D printing has come a long way, but most parts (especially FDM) still have that tell-tale “layered” look. They are also “anisotropic,” which is a fancy way of saying they might split along the layer lines if you put too much stress on them.

4. Material Selection

- 3D Printing: You’re limited to what can be turned into a filament, powder, or resin. It’s a growing list, but it’s still a subset.

- Injection Molding: If it’s a plastic, you can mold it. Want glass-filled nylon for high heat? Or flexible TPE that feels like rubber? You’ve got the keys to the entire polymer kingdom.

Ready to wrap this up with the “When to Use Which” summary and some real-world examples?

So, where do you actually put your money? Let’s stop talking theory and look at the real-world scenarios that usually land on my desk.

When to Stick with 3D Printing

Honestly, if you’re still in the “what if” phase, 3D printing is your best friend.

- The Prototyping Phase: If you need to feel the part in your hand, test the fit, or show a “looks-like-works-like” model to an investor by Monday, don’t even look at a mold.

- Bridge Manufacturing: This is a move I see smart teams make all the time. You’ve finished your design, and you’ve ordered your injection mold—but that mold won’t be ready for two months. You print 500 units now to start selling and seeding the market. It keeps the momentum alive.

- The “Impossible” Geometries: Sometimes, a designer goes wild with internal lattices or organic shapes that a steel tool simply can’t reach. If your part looks like a piece of coral, printing might be your only choice.

When to Pull the Trigger on Injection Molding

This is for when the “experiment” is over and the “business” begins.

- High-Volume Certainty: If you’re confident you’ll sell 5,000+ units, the upfront pain of the mold pays for itself in weeks. It’s the difference between a hobby and a production line.

- The “Retail Feel”: If your product is going to sit on a shelf at Best Buy or IKEA, it needs to feel “real.” No layers, no rough edges—just the smooth, heavy, consistent feel that only high-pressure molding delivers.

- The Medical/Auto Standards: When lives are on the line, “good enough” isn’t an option. Injection molding gives you access to certified, medical-grade resins that have been tested for decades.

The Cheat Sheet: Quick Tools & Materials

If you’re shopping for the “how,” here’s a quick pulse check on what’s actually being used in the industry right now:

| Method | Recommendation | Why? |

|---|---|---|

| 3D Printing (Pro) | Formlabs Form 4 or HP MJF | High detail (SLA) or rugged, functional parts (Nylon). |

| 3D Printing (Workhorse) | Bambu Lab X1-Carbon | It’s basically the “iPhone” of printers—fast, reliable, and just works. |

| Molding (The Go-To) | ABS or Polypropylene (PP) | ABS for toughness (think LEGO); PP for anything that needs to flex (think bottle caps). |

| Molding (The Pro) | Polycarbonate (PC) | When you need it to be bulletproof and crystal clear. |

The Final Word

Is one “better” than the other? Not really. It’s like asking if a hammer is better than a screwdriver.

Actually, the most successful projects I see don’t choose one side—they use both. They prototype with 3D printing, use it to build “bridge” stock, and then transition to injection molding once the market proves them right.

To be honest, the biggest mistake isn’t choosing the “wrong” tech; it’s waiting too long to make a choice at all. Look at your volume, check your bank account, and just start making. You can always pivot later.

The Reality of Customization: 3D Printing in Action

I remember a small medical tech firm trying to solve a specific problem: custom surgical guides for spinal operations. Every patient’s spine is different, so a “standard” part was useless.

If they had gone the injection molding route, they would have been dead in the water. Can you imagine machining a $10,000 steel mold for a part you’re only going to use once? It’s absurd. By using SLA (Stereolithography), they were able to take a patient’s CT scan and print a biocompatible guide in under 24 hours. The cost per part was high—maybe $50 for a bit of plastic—but the “tooling” cost was zero. Actually, in this niche, 3D printing isn’t just a choice; it’s the only reason the business exists.

The Power of the Pivot: Scaling with Injection Molding

Now, compare that to a startup I worked with that designed a “smart” reusable water bottle. They started on Kickstarter and used 3D printing (specifically Multi Jet Fusion) for their first 200 “beta” units. It was great for getting feedback, but as soon as they hit 5,000 orders, the math turned ugly.

They were paying nearly $12 per housing to print them. By biting the bullet and investing $25,000 in a high-quality aluminum mold, they dropped that cost to $0.85 per unit. To be honest, that $25,000 felt like a fortune at the time, but they made that money back in the first month of shipping. That’s the “beast” of injection molding—it’s a massive wall to climb, but the view on the other side is incredibly profitable.

What’s Actually Next?

We’re moving toward a world where you don’t really have to “pick a side” anymore. Have you heard about 3D-printed tooling? It’s a fascinating middle ground. Companies are now 3D printing the molds themselves using high-temp resins. You get the speed of a printer but the material properties of a molded part. It’s perfect for those “in-between” runs of 50 to 100 pieces where neither traditional method quite fits.

The Bottom Line

At the end of the day, your choice shouldn’t be about which tech is “cooler.” It’s about your specific finish line.

- Are you still iterating? Print it. * Is your design “frozen” and your order book full? Mold it. Mostly, just don’t get stuck in “analysis paralysis.” The most successful manufacturers I know are the ones who aren’t afraid to use a 3D printer to fail fast, so they can use an injection molder to succeed big.

Which one are you ready to start with today?

FAQs

Is 3D printing actually “cheaper” than injection molding?

Honestly? Only at the start. If you’re making one part, 3D printing is a bargain because you aren’t paying for a $10,000 mold. But once you hit a certain volume—usually around 500 to 1,000 units—the “per-part” cost of printing starts to hurt. Think of it like a taxi vs. buying a car: the taxi is cheaper for a single trip, but if you’re driving 100 miles every day, you’re better off owning the vehicle.

Can I use the same design for both processes?

Probably not. This is a trap many designers fall into. 3D printing lets you get away with “lazy” design—you can have thick blocks of plastic and sharp internal corners. If you try to shove that same design into an injection mold, it’ll warp, sink, or get stuck. If you plan on eventually molding your part, start designing for it now (think draft angles and uniform wall thickness), even if you’re just printing prototypes for now.

Which process produces stronger parts?

Injection molding wins this one, hands down. Because the plastic is injected as one continuous, molten mass under pressure, it’s structurally consistent throughout. 3D printed parts have “layers,” and those layers are essentially tiny fault lines. If you stress a printed part the wrong way, it’ll split like a piece of wood.

How fast can I get my parts?

If you need it tomorrow, print it. You can go from a CAD file to a physical part in hours. Injection molding is a waiting game. Even a “fast” mold takes 2 to 4 weeks to machine, and that’s before you even start the actual production run.

Is 3D printing only for plastic?

Actually, no. Metal 3D printing (SLM/DMLS) is huge in aerospace and medical implants. You can also print in ceramics or wax for investment casting. However, for most consumer products, we’re usually talking about various types of resins and thermoplastics.

Wait, what about 3D printing the mold?

That’s the “pro move” right now. If you need 50 real, molded parts, you can 3D print the mold inserts using a high-temp resin. It’s a great way to test the actual production material without spending a fortune on a steel tool. Just don’t expect that printed mold to last for 10,000 shots—it’ll probably give up after 50.

English

English bahasa Indonesia

bahasa Indonesia