The Reality of Low Volume Injection Molding: Bridging the Gap

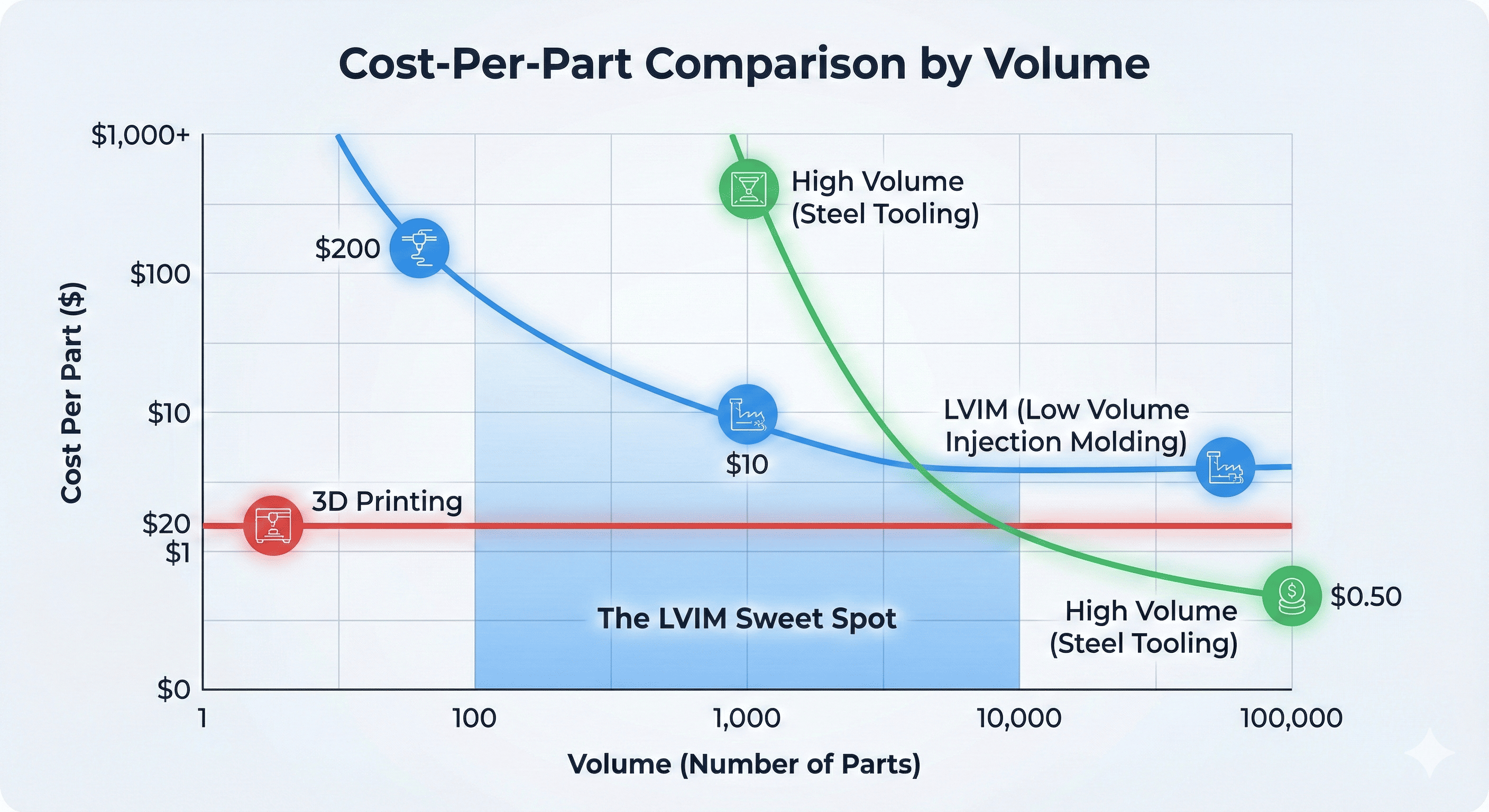

In manufacturing, we often hit a wall. You’ve outgrown the shaky tolerances of 3D printing, but you aren’t ready to drop $50,000 on a hardened steel mold that takes three months to build. This is where Low Volume Injection Molding (LVIM) steps in. It’s the “sweet spot” for hardware teams who need real parts, real materials, and real speed—without the enterprise-level debt.

What are we actually talking about?

Think of LVIM as the agile cousin of mass production. While traditional molding obsesses over “millions of cycles,” LVIM is designed for the 100 to 10,000 unit range.

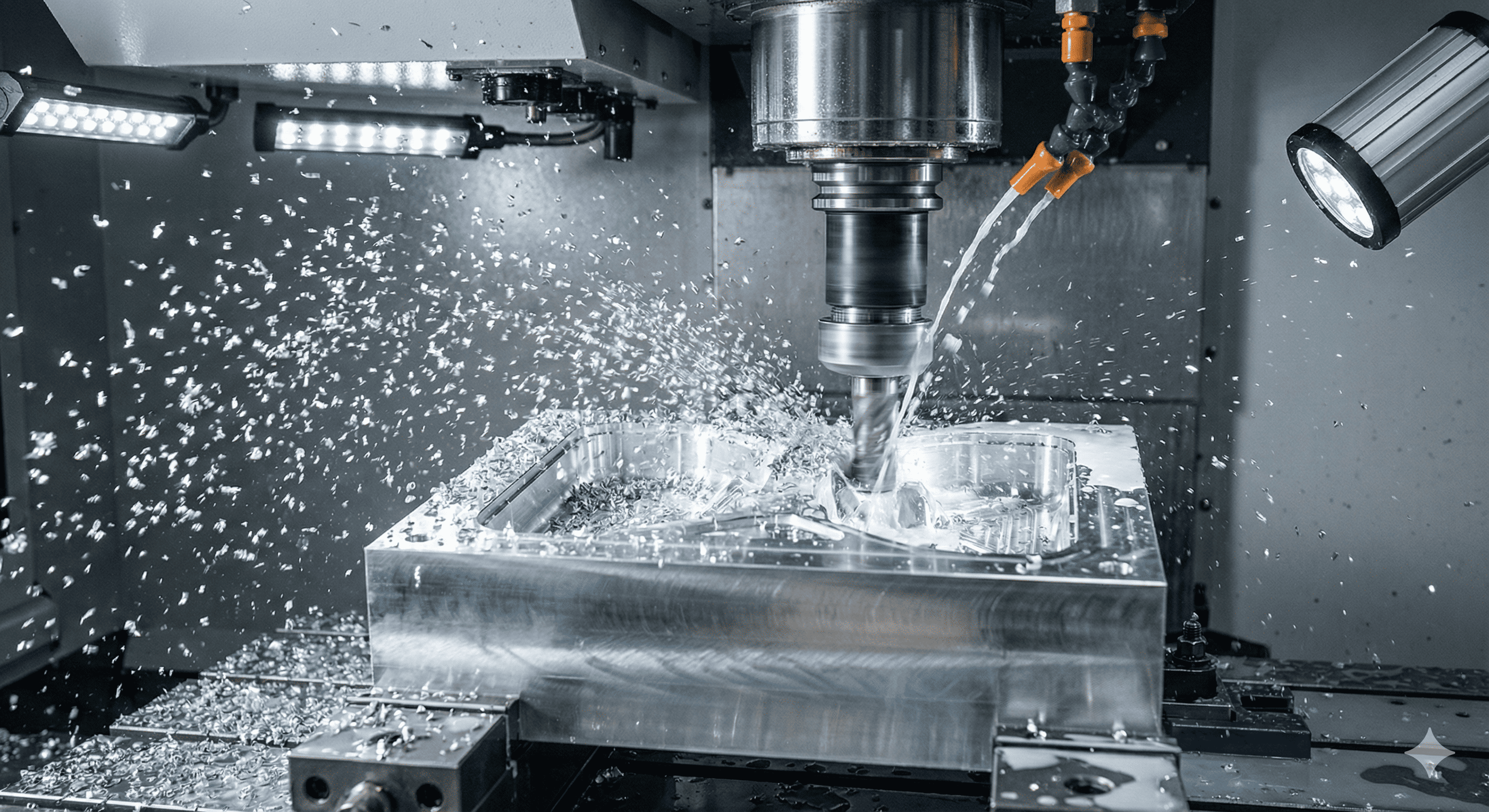

The real magic happens in the tool shop. Instead of grueling weeks spent machining hardened steel, we use high-grade aluminum or pre-hardened steel alloys. Why? Because aluminum sheds heat faster and cuts like butter. This shifts the conversation from “How many months?” to “How many days until we ship?”

Why bother with LVIM?

Honestly, the biggest win isn’t just the lower price tag—it’s the peace of mind.

- Market Testing without the Risk: Imagine launching a product, realizing the buttons feel “mushy,” and having to scrap a $60k tool. With low-volume molding, you can pivot. If the market wants a different texture or a slight tweak in the grip, your wallet won’t scream when you update the aluminum insert.

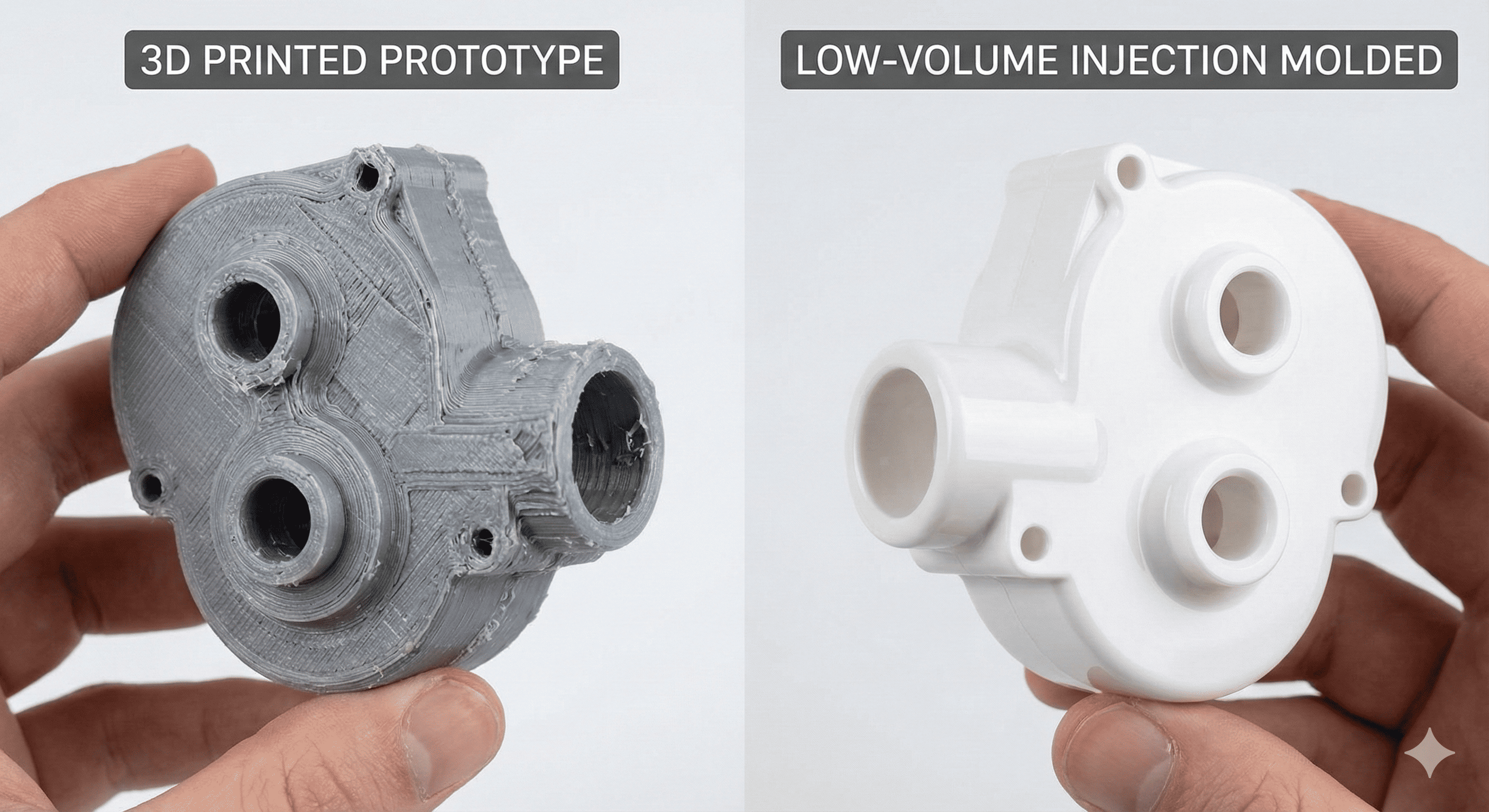

- The “Real Material” Advantage: Let’s be honest, 3D prints feel like 3D prints. They’re great for visual checks, but they don’t behave like the final product. LVIM uses the exact production-grade thermoplastics (like ABS, PC, or Nylon) your customers will actually hold. You get the snap-fits, the heat resistance, and the surface finish of a retail product from day one.

- Bridge Tooling: While your massive “multi-cavity” steel mold is being carved in a factory somewhere, your aluminum “bridge” tool is already pumping out parts. You’re in the market, generating revenue, and gathering feedback while your competitors are still looking at CAD files.

The Trade-off

It’s not all sunshine and fast lead times, though. Aluminum tools are softer. They won’t last for a million shots, and you might have to sacrifice some of the most complex internal cooling lines. But for a startup or an R&D team? That’s a trade-off most of us would make in a heartbeat.

It’s about getting “good enough” to be “great” in the eyes of your customers, as fast as humanly possible.

When to Pull the Trigger: Choosing the Right Moment for Low Volume Molding

It’s easy to get caught up in the “let’s just 3D print it” mindset, but there comes a point where that stops making sense—both for your budget and your sanity. LVIM isn’t just a middle ground; it’s a strategic move. So, when should you actually use it?

1. The Prototyping Final Exam

Think of this as the “Beta” phase. You’ve done your FDM or SLA prints, and the shape looks right. But will the clip snap? Will the heat from the internal electronics warp the casing? By using low-volume molding for your final prototypes, you’re testing the actual physics of the part. You get to see how the plastic flows into the corners and how it shrinks—real-world data you just can’t get from a printer.

2. Building the “Bridge”

This is arguably the most common use case. Suppose your product is a hit, and you’ve ordered a high-capacity steel mold. That tool might take 12 to 16 weeks to arrive. Can you afford to wait four months to start selling? Probably not. A “Bridge Tool” (an aluminum mold) gets you through those first few months. It keeps your assembly line moving while the heavy-duty iron is still being forged.

3. Pilot Production & Small Niches

Sometimes, “low volume” is actually your “full volume.” If you’re building medical devices, high-end automotive dash kits, or specialized drone components, you might only ever need 2,000 units a year. In these cases, spending $80,000 on a multi-cavity tool is just bad business. LVIM becomes your permanent production solution, keeping your overhead low and your margins healthy.

The Material Playbook: What Can You Actually Mold?

People often ask, “Can I use the same plastic as the big guys?” Absolutely. In fact, that’s the whole point.

The Heavy Hitters: Thermoplastics

Most of what we touch—from your toothbrush to your car’s trim—is made of thermoplastics. These are the stars of the show because they can be melted, injected, and cooled repeatedly.

- ABS: The reliable workhorse. Tough, impact-resistant, and finishes beautifully.

- Polycarbonate (PC): When you need it to be clear or incredibly strong.

- Nylon (PA): The engineering choice for gears and moving parts that need to resist wear.

The Specialists: Thermosets

These are a different breed. Once they set, they’re done—like baking a cake, you can’t melt it back into batter. They’re fantastic for high-heat environments or electrical insulation where you absolutely cannot have the part melting under pressure.

Picking Your Fighter

Choosing a material isn’t just about strength; it’s about the “shrink.” Different plastics behave differently when they hit the cold walls of a mold. If you switch materials halfway through a project, your parts might not fit together anymore. It’s always better to pick your production-intent material during the low-volume stage to avoid nasty surprises later.

When to Pull the Trigger: Choosing the Right Moment for Low Volume Molding

It’s easy to get caught up in the “let’s just 3D print it” mindset, but there comes a point where that stops making sense—both for your budget and your sanity. LVIM isn’t just a middle ground; it’s a strategic move. So, when should you actually use it?

1. The Prototyping Final Exam

Think of this as the “Beta” phase. You’ve done your FDM or SLA prints, and the shape looks right. But will the clip snap? Will the heat from the internal electronics warp the casing? By using low-volume molding for your final prototypes, you’re testing the actual physics of the part. You get to see how the plastic flows into the corners and how it shrinks—real-world data you just can’t get from a printer.

2. Building the “Bridge”

This is arguably the most common use case. Suppose your product is a hit, and you’ve ordered a high-capacity steel mold. That tool might take 12 to 16 weeks to arrive. Can you afford to wait four months to start selling? Probably not. A “Bridge Tool” (an aluminum mold) gets you through those first few months. It keeps your assembly line moving while the heavy-duty iron is still being forged.

3. Pilot Production & Small Niches

Sometimes, “low volume” is actually your “full volume.” If you’re building medical devices, high-end automotive dash kits, or specialized drone components, you might only ever need 2,000 units a year. In these cases, spending $80,000 on a multi-cavity tool is just bad business. LVIM becomes your permanent production solution, keeping your overhead low and your margins healthy.

The Material Playbook: What Can You Actually Mold?

People often ask, “Can I use the same plastic as the big guys?” Absolutely. In fact, that’s the whole point.

The Heavy Hitters: Thermoplastics

Most of what we touch—from your toothbrush to your car’s trim—is made of thermoplastics. These are the stars of the show because they can be melted, injected, and cooled repeatedly.

- ABS: The reliable workhorse. Tough, impact-resistant, and finishes beautifully.

- Polycarbonate (PC): When you need it to be clear or incredibly strong.

- Nylon (PA): The engineering choice for gears and moving parts that need to resist wear.

The Specialists: Thermosets

These are a different breed. Once they set, they’re done—like baking a cake, you can’t melt it back into batter. They’re fantastic for high-heat environments or electrical insulation where you absolutely cannot have the part melting under pressure.

Picking Your Fighter

Choosing a material isn’t just about strength; it’s about the “shrink.” Different plastics behave differently when they hit the cold walls of a mold. If you switch materials halfway through a project, your parts might not fit together anymore. It’s always better to pick your production-intent material during the low-volume stage to avoid nasty surprises later.

Cracking the Code: The Process and the Price Tag

How do we actually go from a digital file to a box of parts in two weeks? It isn’t magic, but it does require a bit of “trimming the fat” from traditional manufacturing.

From CAD to Cavity: The LVIM Process

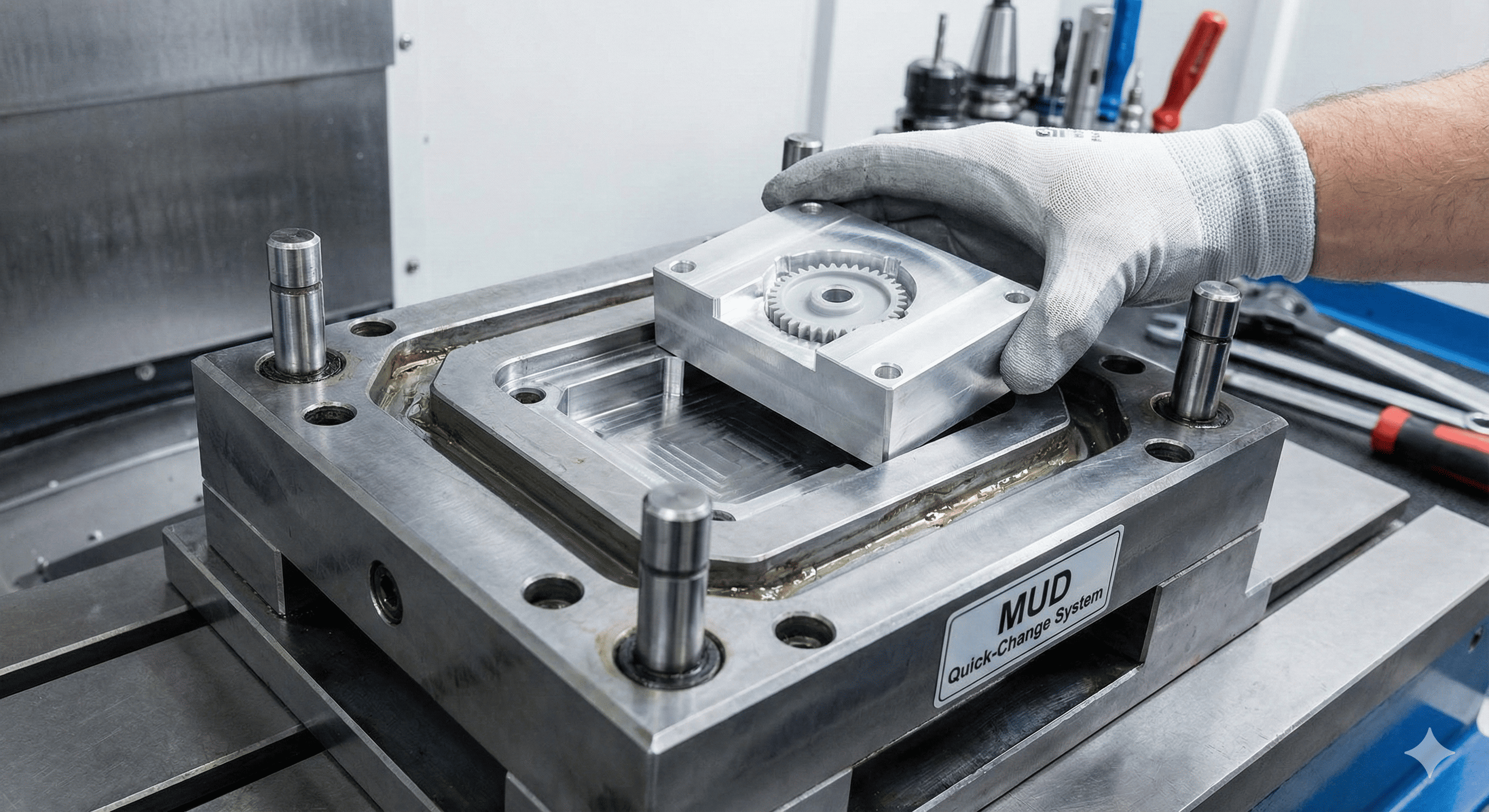

The heavy lifting happens during Mold Design. In high-volume production, you’re worried about every micro-second of cycle time, so you build complex “water jackets” for cooling. In low-volume molding, we simplify. We use Master Unit Die (MUD) bases—standardized frames that hold custom inserts. This means we only have to cut the “cavity” (the part shape) and not the entire massive block of metal.

Once the mold is machined—usually via high-speed CNC—it’s clamped into the press. The injection cycle itself is a dance of pressure and temperature. Molten resin is shoved into the tool, held under immense pressure to prevent “sink marks,” and then popped out. Because we use aluminum, the tool sheds heat quickly, which is a nice bonus for keeping things moving.

Quality Control: Not “Cheap,” Just “Fast”

A common misconception is that “low volume” means “low quality.” In reality, the parts are often better because the production runs are shorter. An operator can keep a much closer eye on 500 parts than they can on 500,000. We’re still checking tolerances with CMMs (Coordinate Measuring Machines) and ensuring the color matches your brand’s spec.

The Big Question: What’s This Going to Cost?

Let’s talk numbers—or at least, what drives them. In injection molding, you’re always fighting the Initial Setup Cost.

1. The Tooling Bill: This is your biggest hurdle. For LVIM, you’re looking at a range—maybe $2,000 for a simple gear and up to $15,000 for a complex enclosure with “side-actions” (moving parts in the mold). Compare that to $50,000+ for a production steel tool.

2. Part Price: Here’s the catch. Your “per-part” cost will be higher than at mass scale. Why? Because you’re spreading that setup time and machine calibration over 500 units instead of a million.

3. Geometry Matters: Want a “zero-degree” wall? Or a deep, narrow hole? That adds cost. If you can design with generous draft angles (tapered sides), the part pops out easier, the mold lasts longer, and the price drops.

How to Save a Few Grand

If you want to keep the invoice lean, think about Surface Finish. A high-gloss, “Class A” mirror finish requires manual polishing by a human being for hours. If you can live with a “Protomold” textured finish or a standard machine finish, you’ll save a significant chunk of change and a few days of lead time.

The Rivalry: Low Volume Molding vs. The Field

Choosing a manufacturing method shouldn’t feel like a guessing game. Usually, it comes down to a “break-even” point. When does the speed of a 3D printer stop being an advantage? When does the cost of a CNC-machined block become overkill?

Here is the “cheat sheet” most engineers use to decide:

| Feature | 3D Printing (SLA/SLS) | CNC Machining | Low Volume Injection Molding |

|---|---|---|---|

| Best Quantity | 1 – 10 parts | 1 – 50 parts | 100 – 10,000 parts |

| Lead Time | 2 – 5 days | 1 – 2 weeks | 2 – 4 weeks |

| Material Choice | Limited (Resins/Filaments) | Any metal or plastic | Unlimited (Production Resins) |

| Surface Finish | Visible layers (rough) | Tool marks (smooth) | Retail-ready (Polished/Textured) |

| Unit Cost | Fixed (High) | High | Decreases with volume |

The “Cost Cross-Over”

Think of it this way: 3D printing is like taking a taxi. It’s convenient for a short trip, but you wouldn’t use one to drive across the country. Low Volume Injection Molding is like leasing a car. There’s a bit of paperwork and a down payment (the mold cost) at the start, but after that, every mile—or every part—is significantly cheaper.

Real-World Impact: The SolarSack Success

Let’s look at a real example. A Danish company called SolarSack developed a simple, life-saving product: a plastic bag that uses UV radiation to purify water.

They needed a specific water tap that was food-grade, leak-proof, and cheap enough for developing markets.

- The Problem: 3D printing couldn’t handle the food-grade material requirements, and a “full-scale” steel mold was a $40,000 risk for a startup.

- The Solution: They used Low Volume Molding. It allowed them to iterate through six different designs of the tap without losing their shirts.

- The Result: They produced the first 10,000 units using this “soft” tooling. Once the product was a proven success and the design was locked, they finally invested in the “heavy” steel production tools.

What’s Next? The Future of Small Batches

We’re moving away from the “one-size-fits-all” factory model. The future of LVIM is getting smarter and greener.

- AI-Driven Molds: We’re seeing more software that uses AI to “predict” how plastic will flow before we even cut the metal. This means the first part off the line is much more likely to be perfect, reducing waste.

- Eco-Friendly Resins: With the rise of “Circular Economy” goals, more shops are offering recycled resins or bio-based plastics (like those made from corn starch) specifically for short-run projects. It’s a great way for brands to test “green” versions of their products without committing to a massive production overhaul.

- Desktop Automation: Small-scale robotic arms are now being used to “pick and place” parts even in small shops, which helps keep the labor costs of low-volume runs competitive with overseas mass production.

The Bottom Line

Low Volume Injection Molding isn’t just a “budget” version of mass production. It’s a tool for the fast-movers. It’s for the teams who want to get a high-quality product into their customers’ hands while their competitors are still arguing over a prototype.

Wrapping It Up: Is Low Volume Molding Your Next Move?

We’ve covered the “how,” the “what,” and the “how much.” But at the end of the day, low volume injection molding is more than just a line item on a manufacturing budget—it’s a strategy for survival in a market that moves at the speed of light.

The Takeaway

If you are sitting on a design that’s ready for the world, don’t let the “All or Nothing” myth of traditional manufacturing hold you back. You don’t need to choose between a plastic part that feels like a toy (3D printing) and a massive financial gamble (hardened steel tooling).

Low Volume Injection Molding gives you:

- The Professional Edge: Parts that look and act like they belong on a retail shelf.

- Financial Breathing Room: Lower upfront costs that let you keep your capital for marketing and growth.

- The Ability to Pivot: If your customers want a change, you aren’t married to a $50k piece of iron.

A Final Tip from the Shop Floor

Before you send off your CAD files for a quote, do yourself a favor: Talk to your molder early. A ten-minute conversation about draft angles or wall thickness can often save you thousands of dollars in tooling modifications. Most low-volume shops are used to working with “messy” R&D files—they expect to help you refine the design for the mold. Take advantage of that expertise.

Summary Table: The Lifecycle of a Part

| Phase | Quantity | Goal | Best Method |

|---|---|---|---|

| Concept | 1 - 5 | Form & Fit | 3D Printing |

| Validation | 10 - 50 | Functional Testing | CNC Machining |

| Market Launch | 100 - 5k | Revenue & Feedback | Low Volume Molding |

| Mass Scale | 50k+ | Unit Cost Optimization | High Volume (Steel) |

The gap between “idea” and “product” is narrower than it’s ever been. Whether you’re building the next great medical device or a niche piece of consumer tech, LVIM is the bridge that gets you across.

Frequently Asked Questions

When it comes to low volume molding, the same few questions tend to pop up on the shop floor. Here’s the “straight talk” on what you really need to know.

How “low” is low volume, exactly?

While there’s no law written in stone, the industry generally considers anything from 100 to 10,000 units as the sweet spot. Below 100, you’re usually better off with 3D printing or CNC machining. Above 10,000, the wear and tear on an aluminum mold might start to affect your tolerances, making a transition to steel a smarter long-term bet.

Will my parts look “prototype-y”?

Not at all. That’s the beauty of it. Because we’re using real injection molding presses and production-grade resins, your parts will have the same weight, texture, and structural integrity as something you’d buy at a big-box retailer. If you want a specific texture (like a matte finish or a spark-eroded surface), we can apply that directly to the mold.

Can I make changes to the mold once it’s built?

Yes—to a point. It’s much easier to remove metal than to add it. If you need to make a hole smaller or a wall thinner, we can usually “machine away” more of the mold. Adding material (making a part thicker) is trickier and might require welding or a new insert. This is why aluminum is so popular; it’s incredibly forgiving and fast to modify compared to hardened steel.

Why is the lead time so much shorter?

Traditional molds are like bank vaults—they are built to survive millions of high-pressure cycles. That takes time. Low volume tools use simplified designs and “softer” metals that can be cut at much higher speeds on a CNC machine. We also skip the complex automated cooling systems used in mass production, which trims weeks off the fabrication schedule.

Is there a limit to the materials I can use?

If it’s a thermoplastic, we can mold it. From basic Polypropylene to high-performance PEEK or glass-filled Nylon, the process handles them all. The only real “limit” is ensuring your material choice matches the mold design (since different plastics shrink at different rates).

What if I eventually need 100,000 parts?

Think of your low volume tool as your “market entry” tool. Once your sales volume justifies the investment, you take the lessons learned from the low-volume run—like where the sink marks appeared or which tolerances were tight—and apply them to a multi-cavity steel production tool. You’ve essentially used LVIM to “de-risk” your mass production phase.

English

English bahasa Indonesia

bahasa Indonesia