Introduction

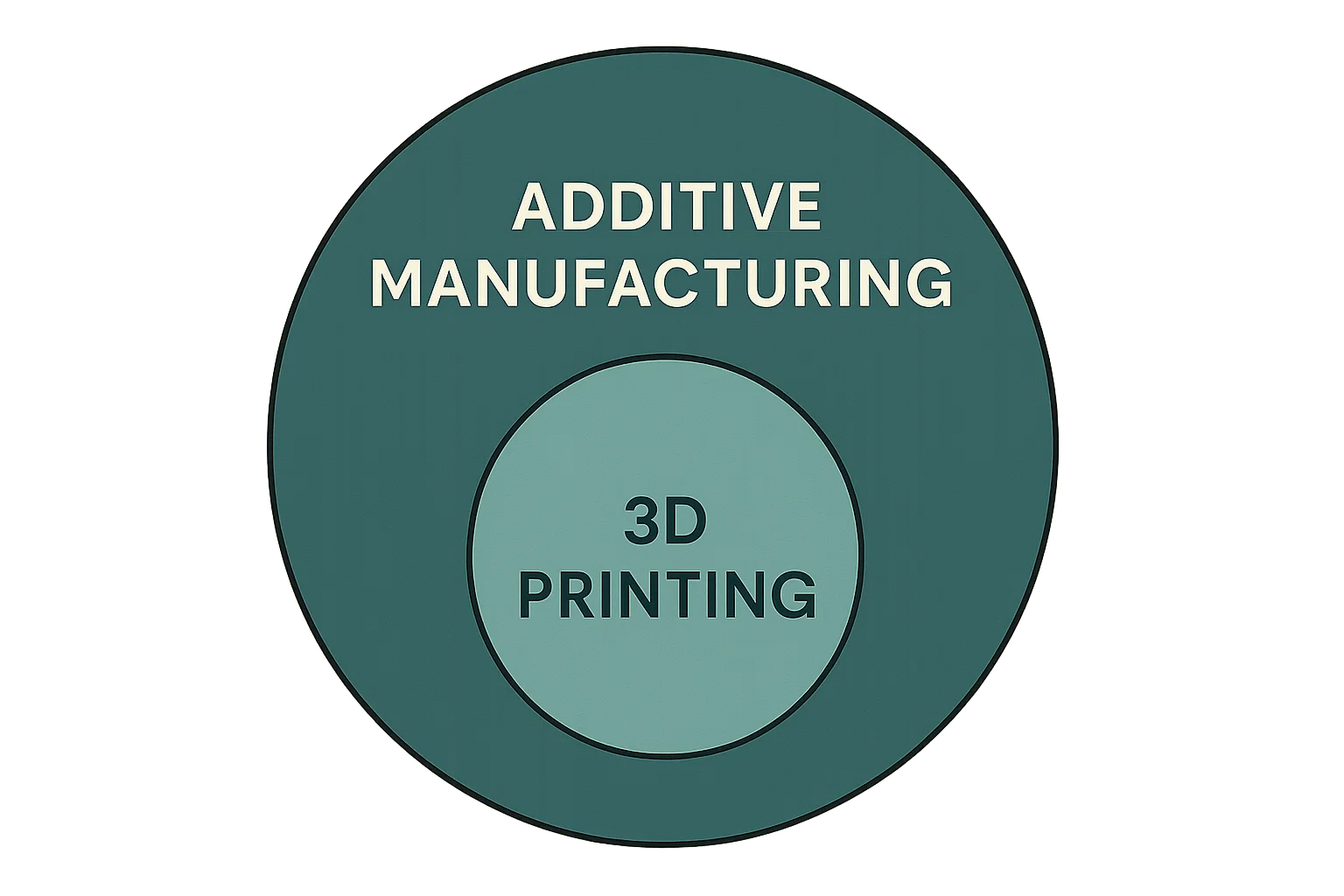

While often used interchangeably, 3D printing and additive manufacturing are not synonymous; rather, 3D printing is a specific form of the broader industrial process known as additive manufacturing.

To put it simply, think of it this way: All 3D printers do additive manufacturing, but not all additive manufacturing is done by what we typically call a 3D printer. It's like saying all cars are vehicles, but not all vehicles are cars (you also have trucks, motorcycles, buses, etc.).

Similarly, 3D printing is a popular type of additive manufacturing, particularly known for its accessibility and use in prototyping and personal projects, but the full scope of additive manufacturing extends far beyond that.

Table for quick overview:

| Feature | 3D Printing (Common Perception) | Additive Manufacturing (Broader Industrial Term) |

| Primary Focus | Prototyping, concept models, hobbyist projects, personal use | Functional end-use parts, industrial production, mass customization |

| Typical Scale | Smaller batches, single prototypes, one-off custom items | Medium to large-scale production, complex assemblies, critical components |

| Common Materials | Primarily thermoplastics (PLA, ABS, PETG), photopolymer resins | Metals (titanium, aluminum, nickel alloys), high-performance polymers (PEEK, Ultem), composites, ceramics |

| Precision & Quality | More tolerant of error, emphasis on visual representation or rapid iteration | Demands high precision, dimensional accuracy, stringent quality control, often requires post-processing |

| Typical Applications | Product design iteration, educational tools, custom figurines, basic jigs | Aerospace components, medical implants, automotive parts, industrial tooling |

| Cost (Equipment) | Generally lower, accessible desktop and entry-level industrial machines | Significantly higher, specialized industrial-grade systems |

| Relationship | A subset or specific type of additive manufacturing | The overarching industrial field that includes 3D printing |

To truly understand this distinction, let's first delve into the foundational concept of 3D printing.

What is 3D Printing?

At its core, 3D printing is a process of creating three-dimensional objects from a digital design by adding material layer by layer. Unlike traditional subtractive manufacturing methods, which remove material from a larger block (like machining or carving), 3D printing builds up the object from scratch. This "additive" approach is fundamental to its operation.

The basic process typically involves:

- Creating a 3D Model: This usually starts with a digital design, often created using Computer-Aided Design (CAD) software, or by scanning an existing object.

- Slicing the Model: The digital 3D model is then "sliced" by specialized software into hundreds or thousands of thin, horizontal layers.

- Material Deposition: A 3D printer then reads these slices and precisely deposits or solidifies material layer by layer, according to the cross-section of each slice, until the entire object is formed.

Several common technologies underpin the practice of 3D printing, each suited for different materials and applications:

- Fused Deposition Modeling (FDM) / Fused Filament Fabrication (FFF): This is perhaps the most well-known technology, used in many desktop 3D printers. It works by extruding a thermoplastic filament through a heated nozzle, melting the material, and depositing it layer by layer onto a build platform.

- Stereolithography (SLA): This method uses a UV laser to cure (harden) liquid photopolymer resin layer by layer. The laser traces the cross-section of an object in a vat of resin, solidifying it.

- Selective Laser Sintering (SLS): SLS employs a high-power laser to selectively fuse small particles of polymer powder into a solid structure. After each layer is solidified, a new layer of powder is spread over the build area.

- Digital Light Processing (DLP): Similar to SLA, but uses a digital projector screen to flash an entire layer of an image at once, rapidly curing the resin.

Historically, and still predominantly, 3D printing has found its primary applications in:

- Prototyping: Rapidly creating physical models of designs for testing and iteration before mass production. This significantly reduces design cycles and costs.

- Hobbyist Projects and Education: Its increasing accessibility has made it popular for personal projects, creating custom items, and as a valuable tool for learning about design and engineering in educational settings.

- Custom Tooling and Fixtures: Producing bespoke tools or jigs for specific manufacturing tasks, often at a lower cost and faster turnaround than traditional methods.

While incredibly versatile for these applications, 3D printing often implies a focus on relatively smaller scale production, often with plastics or resins, and with an emphasis on design iteration rather than end-use critical parts.

Having established what 3D printing entails, we can now elevate our understanding to the encompassing term: additive manufacturing

What is Additive Manufacturing?

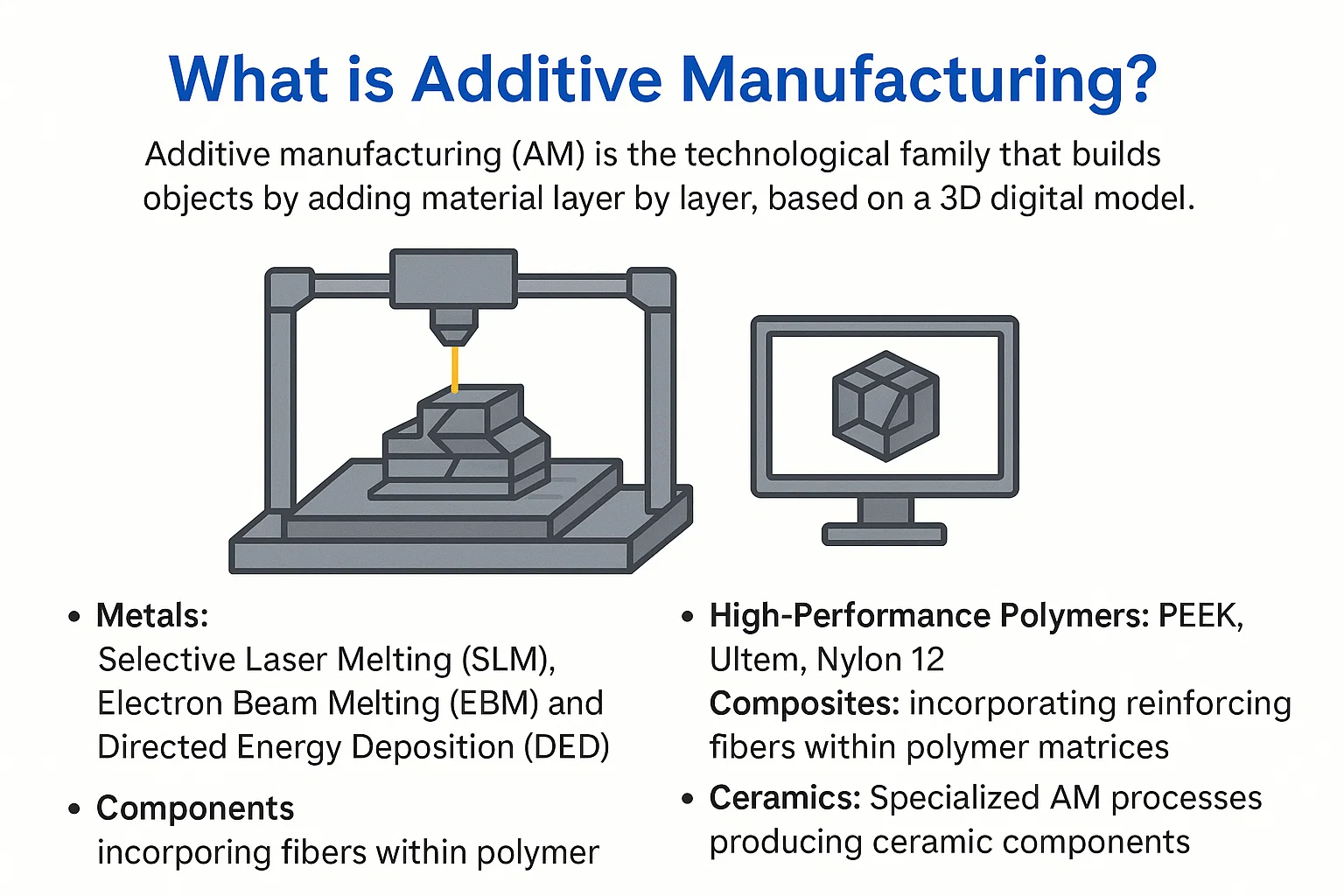

While 3D printing often brings to mind desktop machines fabricating plastic prototypes, additive manufacturing (AM) defines a much broader and more sophisticated industrial process. It is the formal, industry-recognized term for the technological family that builds objects by adding material layer by layer, based on a 3D digital model. Where 3D printing might be seen as the accessible tip of the iceberg, additive manufacturing represents the vast, complex, and powerful bulk beneath the surface, focused on producing high-performance, functional end-use parts.

Additive manufacturing goes beyond mere prototyping to encompass a wide array of industrial applications, where the focus is on robust production, stringent quality control, and the creation of parts that can withstand demanding operational environments. It's about engineering solutions, not just models. This broader concept includes, but is not limited to, the core principles of layer-by-layer construction.

A key differentiator for additive manufacturing is the extensive range of materials it employs, which are often engineered for specific performance characteristics required in demanding industries:

- Metals: This is where AM truly shines for industrial applications. Technologies like Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Directed Energy Deposition (DED) are used to fuse powdered metals (e.g., titanium, aluminum, stainless steel, nickel alloys) or metal wire, creating incredibly strong and complex metallic components for aerospace, automotive, and medical industries.

- High-Performance Polymers: Beyond common plastics, AM utilizes advanced polymers (e.g., PEEK, Ultem, Nylon 12) that offer superior mechanical strength, temperature resistance, and chemical inertness, suitable for demanding industrial uses.

- Composites: Additive manufacturing can also incorporate reinforcing fibers (like carbon fiber or fiberglass) within polymer matrices to create lightweight yet incredibly strong composite parts.

- Ceramics: Specialized AM processes can produce ceramic components that are resistant to high temperatures, wear, and corrosion, useful in aerospace and biomedical fields.

- Sand: For industrial casting, AM can print sand molds and cores directly from digital designs, dramatically speeding up the foundry process.

In essence, additive manufacturing is about transforming digital designs into functional, high-quality, and often highly complex physical products for direct use in various industries, pushing the boundaries of what is possible in design and production.

With a clear understanding of both terms, we can now articulate the key differences that truly distinguish additive manufacturing from what is commonly perceived as 3D printing.

Key Differences Between Additive Manufacturing and 3D Printing

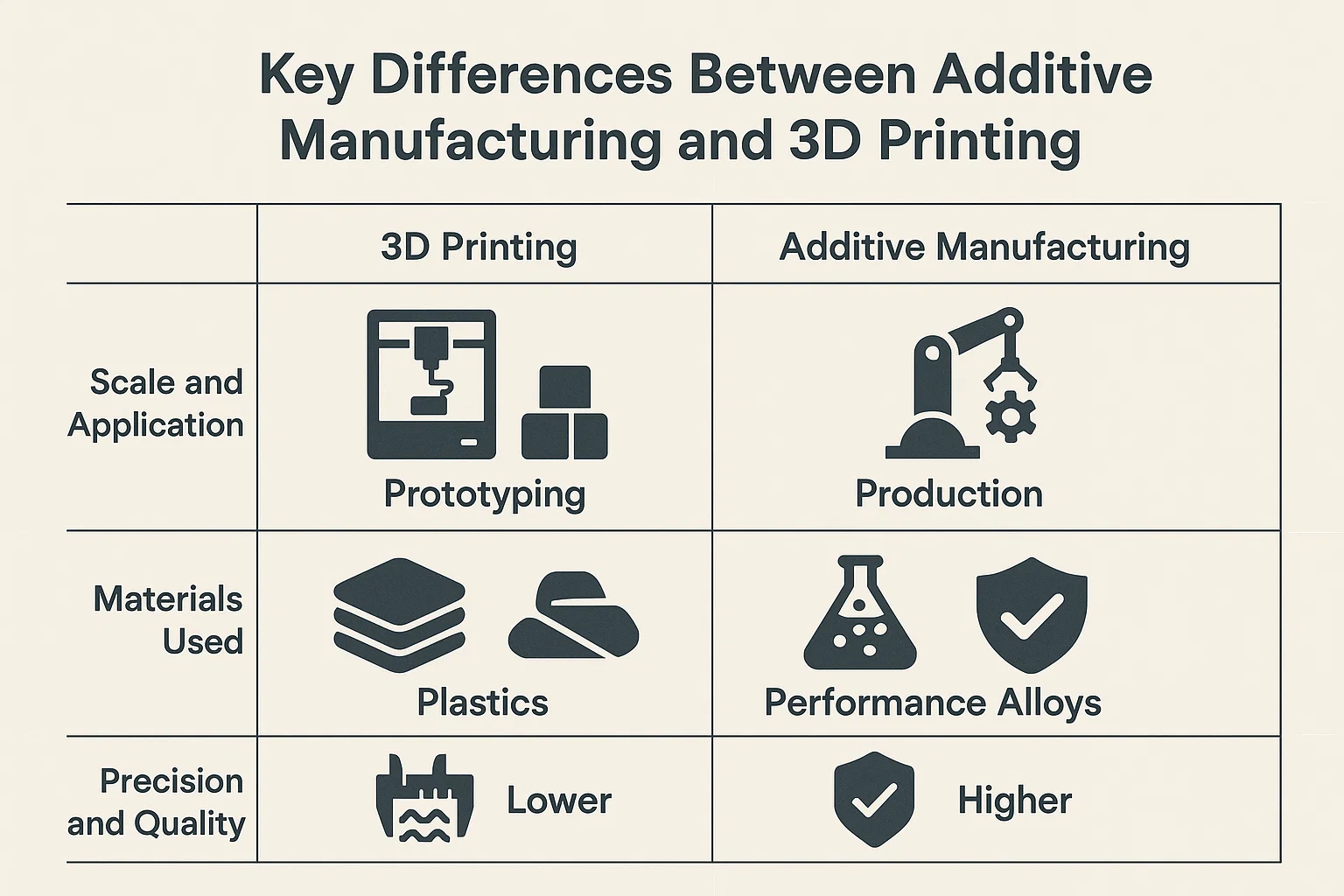

While 3D printing is a form of additive manufacturing, understanding their distinction is vital for appreciating the full scope and capabilities of these technologies. The differences primarily lie in their scale, typical applications, materials used, and the precision and quality expected of their outputs.

Scale and Application: From Prototyping to Production

- 3D Printing: Often associated with smaller scale operations, 3D printing is widely adopted for rapid prototyping, educational purposes, and hobbyist projects. Its strength lies in quickly creating physical models to visualize designs, test form and fit, and iterate concepts efficiently. The emphasis is typically on speed and affordability for conceptualization rather than final product performance.

- Additive Manufacturing: This refers to the industrial-grade application of additive technologies. It's geared towards larger scale production of functional, end-use parts and components. Additive manufacturing facilitates direct digital manufacturing, mass customization, and the production of complex geometries that are impossible or cost-prohibitive with traditional methods. The focus here is on robust performance, reliability, and integration into supply chains for final products.

Materials Used: From Plastics to Performance Alloys

- 3D Printing: Commonly utilizes a narrower range of materials, primarily thermoplastics (like PLA, ABS, PETG) and photopolymer resins. These materials are generally easier to process, less expensive, and ideal for non-critical parts or visual prototypes where high mechanical strength or specific environmental resistances are not paramount.

- Additive Manufacturing: Employs a significantly broader and more advanced array of materials, including high-performance metals (e.g., titanium alloys, nickel-based superalloys, stainless steel), engineering polymers (e.g., PEEK, Ultem), advanced composites, and even ceramics. These materials are selected for their specific mechanical, thermal, and chemical properties, enabling the creation of parts for demanding applications in aerospace, medical, and automotive industries.

Precision and Quality: From Tolerance to Certification

- 3D Printing: While improving, consumer and entry-level industrial 3D printing may have more tolerance for error or less stringent requirements for dimensional accuracy and surface finish. The primary goal is often to create a representative physical model quickly, where minor imperfections might be acceptable.

- Additive Manufacturing: Demands significantly higher precision, accuracy, and quality control for functional, end-use parts. Components produced via additive manufacturing often require rigorous testing, material property validation, and adherence to industry standards (e.g., aerospace certifications, medical device regulations). Post-processing steps (like heat treatment, machining, or surface finishing) are also often critical in additive manufacturing to achieve the required mechanical properties and surface quality, adding to the complexity and precision of the overall process.

The most accurate way to describe it is that 3D printing is a subset of additive manufacturing

The Relationship: Are They the Same?

No, they are not the same, but they are intricately linked. The most accurate way to understand the relationship between 3D printing and additive manufacturing is to recognize that 3D printing is a subset of additive manufacturing.

Think of it using a familiar analogy: All squares are rectangles, but not all rectangles are squares.

- A rectangle is a broader category of quadrilateral with four right angles.

- A square is a specific type of rectangle where all four sides are equal in length.

In the same vein:

- Additive Manufacturing is the overarching, industrial-grade process of building objects layer by layer using various materials and technologies for functional end-use parts. It's the broader "rectangle."

- 3D Printing is a specific, often more accessible and popularized, method within additive manufacturing, typically associated with prototyping, smaller scale production, and a narrower range of materials (often plastics). It's the more specific "square" within the larger "rectangle."

Therefore, when someone refers to 3D printing, they are describing a method that inherently performs additive manufacturing. However, when discussing additive manufacturing, one is encompassing a much wider range of advanced technologies, materials, and applications that extend far beyond what the general public typically associates with "3D printing." The term "additive manufacturing" emphasizes the industrial intent, precision, and performance capabilities crucial for critical applications, while "3D printing" often highlights the more generalized concept of creating three-dimensional objects layer by layer.

Advantages of Additive Manufacturing

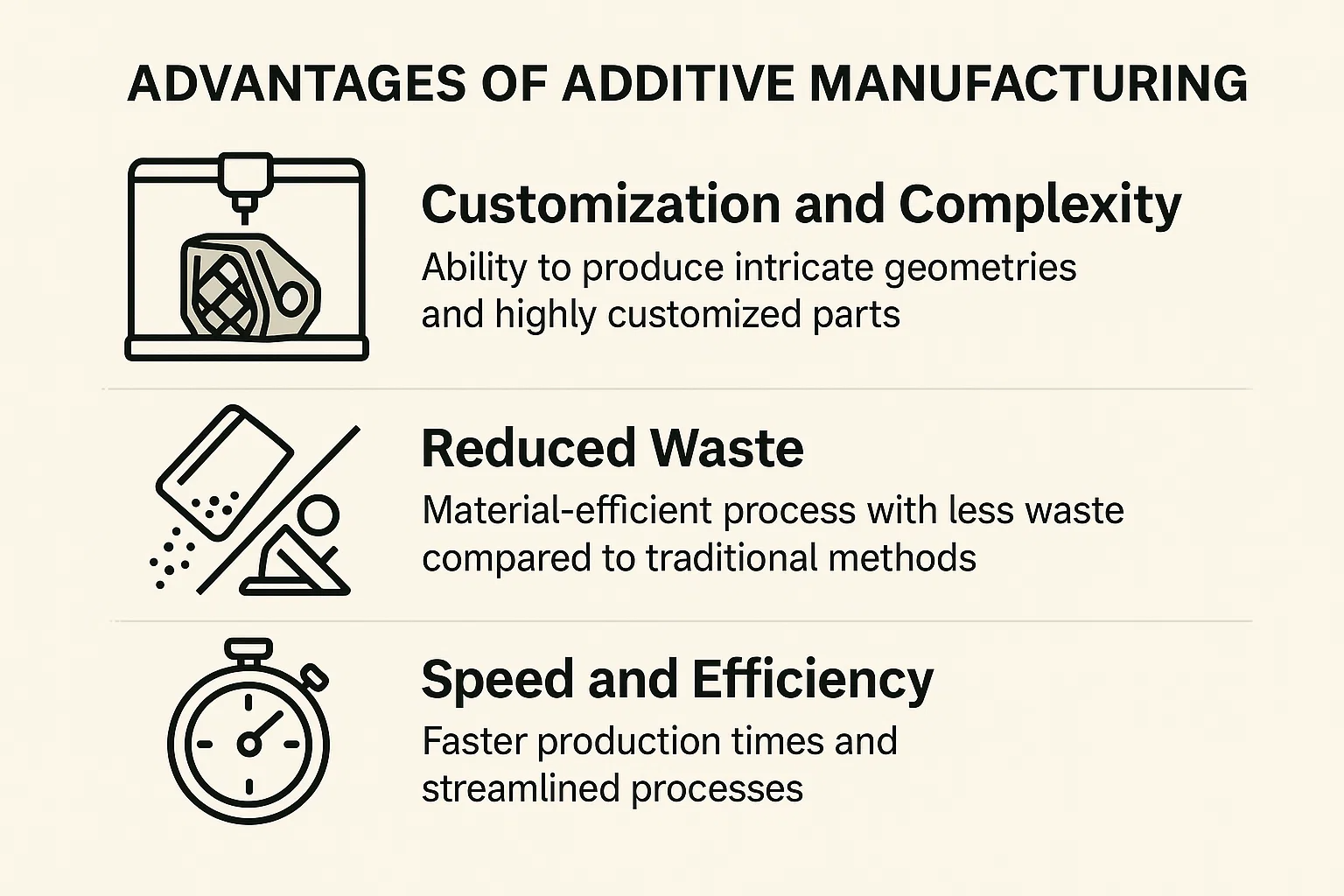

Additive manufacturing has emerged as a transformative technology, offering compelling advantages over traditional manufacturing methods. These benefits are driving its increasing adoption across a multitude of industries, from aerospace to healthcare.

Customization and Complexity

One of the most significant advantages of additive manufacturing is its unparalleled ability to create highly complex geometries and intricate internal structures that are impossible or prohibitively expensive to produce with conventional techniques like machining or molding. This design freedom allows engineers to:

- Optimize Part Performance: Create lightweight structures with internal lattices or honeycomb designs that reduce material usage without compromising strength.

- Consolidate Assemblies: Combine multiple parts into a single, complex component, reducing assembly time, potential failure points, and overall weight.

- Tailor Products to Specific Needs: Produce truly customized products, from patient-specific medical implants to bespoke tooling for a particular manufacturing process, all without the need for new molds or extensive retooling.

Reduced Waste

Unlike subtractive manufacturing, which starts with a larger block of material and removes excess until the desired shape is achieved (often resulting in significant waste), additive manufacturing is an inherently material-efficient process.

- Near Net Shape Production: Only the material precisely needed for the part is used, layer by layer. This significantly reduces material waste, often by 70-90% compared to traditional methods.

- Environmentally Friendly Approach: The reduced material consumption not only lowers costs but also contributes to more sustainable manufacturing practices, aligning with global efforts towards resource conservation and minimized environmental impact.

Speed and Efficiency

Additive manufacturing offers considerable benefits in terms of production timelines, especially for complex or customized parts.

- Faster Production Times: For many applications, particularly prototyping and small-to-medium batch production, AM can produce parts much faster than traditional methods that require extensive setup, tooling, or multiple processing steps.

- Reduced Lead Times: The ability to go directly from a digital design to a physical part without the need for complex tooling or molds dramatically shortens the lead time from concept to finished product. This agility allows companies to respond more quickly to market demands and accelerate product development cycles.

- On-Demand Manufacturing: AM facilitates "print-on-demand" capabilities, reducing the need for large inventories and enabling localized production, further improving efficiency and reducing logistics overhead.

Applications of Additive Manufacturing

The unique capabilities of additive manufacturing, particularly its ability to create complex geometries, use high-performance materials, and facilitate customization, have led to its transformative adoption across a wide range of industries. It's no longer just a prototyping tool but a viable method for producing mission-critical and highly specialized components.

Aerospace

The aerospace industry is a significant early adopter and beneficiary of additive manufacturing, driven by the critical need for lightweight, high-performance parts that can withstand extreme conditions.

- Manufacturing Lightweight Parts for Aircraft: AM allows for the creation of intricate internal structures, like lattices, that can significantly reduce the weight of components (e.g., brackets, air ducts, structural elements) without compromising strength. Lighter aircraft consume less fuel, leading to operational cost savings and reduced emissions.

- Custom Engine Components: Additive manufacturing is used to produce complex turbine blades, fuel nozzles, and other engine parts with optimized cooling channels and geometries impossible to achieve with traditional methods. This enhances engine efficiency and performance.

- On-Demand Replacement Parts: The ability to print parts on demand reduces the need for large inventories and speeds up maintenance and repair processes, particularly for older aircraft where conventional spare parts may be scarce.

Healthcare

Additive manufacturing is revolutionizing healthcare by enabling personalized medicine and innovative medical devices.

- Creating Customized Implants and Prosthetics: Based on patient-sleeve specific anatomical scans, AM can produce custom-fit surgical guides, cranial implants, orthopedic implants (e.g., hip and knee replacements), and prosthetic limbs that perfectly match the patient's anatomy, leading to better fit, comfort, and outcomes.

- Bioprinting of Tissues and Organs: While still largely in the research phase, bioprinting uses "bio-inks" containing living cells to create 3D structures that mimic human tissues and, eventually, potentially organs. This holds immense promise for drug testing, disease modeling, and regenerative medicine, though functional organ printing for transplantation is a long-term goal.

- Surgical Models: Surgeons can use 3D printed anatomical models derived from patient scans to plan complex procedures, improving precision and reducing surgical time.

Automotive

The automotive sector leverages additive manufacturing for both rapid development and the production of specialized components.

- Producing Custom Car Parts and Tooling: AM is used for low-volume production of specialty vehicles, classic car restoration, and highly customized components for performance cars. It's also widely used to print jigs, fixtures, and other manufacturing tools that optimize assembly lines.

- Rapid Prototyping of New Designs: The automotive industry heavily relies on 3D printing for quickly creating prototypes of new designs, from interior components to engine parts, accelerating the design and testing cycles of new vehicle models.

- Optimized Components for Electric Vehicles (EVs): As EVs evolve, AM is being explored for manufacturing lightweight battery enclosures, optimized cooling systems, and specialized motor components to improve efficiency and range.

Challenges and Limitations

Despite its revolutionary potential and numerous advantages, additive manufacturing is not without its hurdles. Several challenges and limitations currently impact its widespread adoption and performance in certain applications. Understanding these is crucial for realistic expectations and for guiding future development in the field.

Cost

The initial investment and ongoing operational expenses associated with additive manufacturing can be significant.

- Initial Investment in Equipment Can Be High: Industrial-grade additive manufacturing machines, especially those capable of processing metals or advanced polymers, represent a substantial capital expenditure. This can be a barrier for smaller companies or for adopting AM for less critical applications.

- Material Costs Can Be Significant: The specialized powders, filaments, or resins required for AM are often considerably more expensive per kilogram than traditional bulk materials used in conventional manufacturing processes. This is particularly true for high-performance metal alloys or custom-engineered polymers.

- Operating Costs: Energy consumption for some processes, specialized gas requirements (e.g., argon for metal printing), and the need for skilled operators also contribute to the overall cost.

Scalability

While AM excels at customization and low-volume production, scaling up for mass manufacturing remains a challenge in many cases.

- Scaling Up Production Can Be Challenging: The layer-by-layer nature of additive manufacturing often results in slower build rates compared to high-volume traditional processes like injection molding or stamping. Producing millions of identical parts efficiently with AM can be difficult and time-consuming.

- Meeting High-Volume Demands: For consumer goods or automotive parts requiring millions of units, traditional manufacturing methods often still hold an economic and speed advantage. AM is currently better suited for complex, customized, or low-to-medium volume production runs.

- Post-Processing Bottlenecks: Many AM parts require significant post-processing (e.g., support structure removal, heat treatment, surface finishing, machining) to achieve the desired mechanical properties and surface quality. These manual or semi-automated steps can add time, cost, and limit the scalability of the entire production workflow.

Material Properties

Ensuring consistent and predictable material properties in additively manufactured parts is an ongoing area of research and development.

- Ensuring Consistent Material Properties: The layer-by-layer build process, rapid heating and cooling cycles, and potential for internal stresses can lead to anisotropic properties (properties that vary with direction) or microscopic defects (e.g., porosity) within the part. This can affect the fatigue strength, ductility, and overall reliability, especially for critical applications.

- Limitations in Material Selection: While the range of compatible materials is growing, it is still more limited compared to traditional manufacturing. Not all materials can be processed additively, and achieving the same material performance as conventionally manufactured parts can be challenging for certain alloys or polymers.

- Qualification and Certification: For highly regulated industries like aerospace and medical, qualifying and certifying additively manufactured parts to meet stringent performance and safety standards is a complex, time-consuming, and expensive process.

Future Trends in Additive Manufacturing

Additive manufacturing is a dynamic field, constantly evolving with rapid advancements in technology, materials science, and integration. Looking ahead, several key trends are poised to further expand its capabilities and solidify its role as a mainstream manufacturing process.

Advancements in Materials

The continuous development of new and improved materials is critical to unlocking AM's full potential for diverse applications.

- Development of New Materials with Improved Properties: Researchers are actively developing novel alloys, high-performance polymers, and composite materials specifically optimized for additive processes. This includes materials with enhanced strength-to-weight ratios, better fatigue resistance, superior thermal properties, and increased biocompatibility. The goal is to match or even surpass the properties of conventionally manufactured parts.

- Use of Nanomaterials in Additive Manufacturing: The incorporation of nanoparticles and other nanomaterials into AM processes holds promise for creating parts with unprecedented properties. This could lead to materials with self-healing capabilities, increased conductivity, or superior toughness, opening doors to entirely new functional applications.

- Multi-Material Printing: The ability to precisely combine different materials within a single print, creating parts with varying properties in different regions, is a significant area of focus. This could lead to components with soft and rigid sections, conductive and insulating pathways, or integrated sensors.

Automation and AI

The integration of automation and artificial intelligence (AI) is set to enhance the efficiency, reliability, and intelligence of additive manufacturing workflows.

- Integrating AI for Process Optimization: AI and machine learning algorithms are being developed to optimize every stage of the AM process, from design generation (generative design) to real-time process monitoring and quality control. AI can predict potential print failures, suggest optimal build parameters, and even identify new material combinations.

- Automated Design and Production Workflows: Automation is streamlining pre-processing (e.g., automated part placement, support generation), in-situ monitoring during the build, and post-processing steps (e.g., automated support removal, surface finishing). This reduces manual intervention, increases throughput, and improves consistency.

- Digital Twins: Creating "digital twins" of additive manufacturing processes and parts allows for real-time monitoring, predictive maintenance, and simulation of performance under various conditions, further enhancing reliability and reducing development cycles.

Increased Adoption

As the technology matures and its benefits become more widely recognized, additive manufacturing is set to see even broader acceptance across various industries.

- Wider Adoption Across Various Industries: Beyond aerospace and medical, industries such as consumer goods, energy, construction, and even food are exploring and implementing AM for specialized applications. The focus is shifting from niche uses to more integrated roles within production chains.

- Growth in Additive Manufacturing Services: The proliferation of specialized AM service bureaus allows companies to leverage the technology without the significant upfront investment in equipment. These service providers offer expertise, a wide range of materials, and production capacity, making AM more accessible.

- Decentralized Manufacturing and Supply Chain Resilience: AM's ability to produce parts on demand and closer to the point of need can contribute to more resilient and localized supply chains, reducing reliance on distant manufacturing hubs and mitigating risks associated with global disruptions.

- Standardization and Certification: As the industry matures, the development of clearer standards and certification pathways for AM processes and materials will build greater confidence and facilitate wider adoption, particularly in highly regulated sectors.

English

English bahasa Indonesia

bahasa Indonesia