Aluminum Molds: A Comprehensive Guide to Types, Applications, and Benefits

In the vast and innovative world of manufacturing, the choice of tooling material is a critical decision that can define a project's success. While steel has long been the traditional workhorse for mold making, a new contender has risen to prominence, revolutionizing the way products are brought to life: aluminum. With its unique combination of properties, from exceptional thermal conductivity to a lightweight nature, aluminum molds have become an indispensable tool for engineers, designers, and manufacturers across a myriad of industries. This guide will take you on a journey into the world of aluminum molds, exploring their types, applications, and the distinct advantages they offer over traditional materials.

What are Aluminum Molds?

An aluminum mold is a tool used in various manufacturing processes to shape and form materials, such as plastics, rubber, and foam. At its core, it is a precision-machined block of aluminum alloy that contains a cavity in the shape of the desired final product. When a molten or pliable material is injected, poured, or pressed into this cavity, it takes on the mold's form and, upon cooling or solidifying, is ejected as a finished part.

A Brief History and Evolution

For decades, steel dominated the mold-making industry due to its incredible hardness and durability. However, the need for faster prototyping and more cost-effective low-to-mid-volume production led to the exploration of alternative materials. Early attempts to use aluminum were met with skepticism, but as advancements in CNC machining and the development of high-strength aluminum alloys (like 7075 and 6061) emerged, the material's potential became undeniable. Today, aluminum is not just a secondary option but a primary choice for a wide range of applications, playing a pivotal role in everything from the development of new automotive parts to the production of everyday consumer goods. Its evolution has mirrored the industry's shift towards rapid innovation and efficiency, making it a cornerstone of modern manufacturing.

Types of Aluminum Molds

Aluminum molds are incredibly versatile, and their design and function are tailored to the specific manufacturing process they are used for. While the base material remains the same, the engineering behind each mold type is unique. We can categorize aluminum molds in two primary ways: based on the manufacturing process they support and based on their specific application.

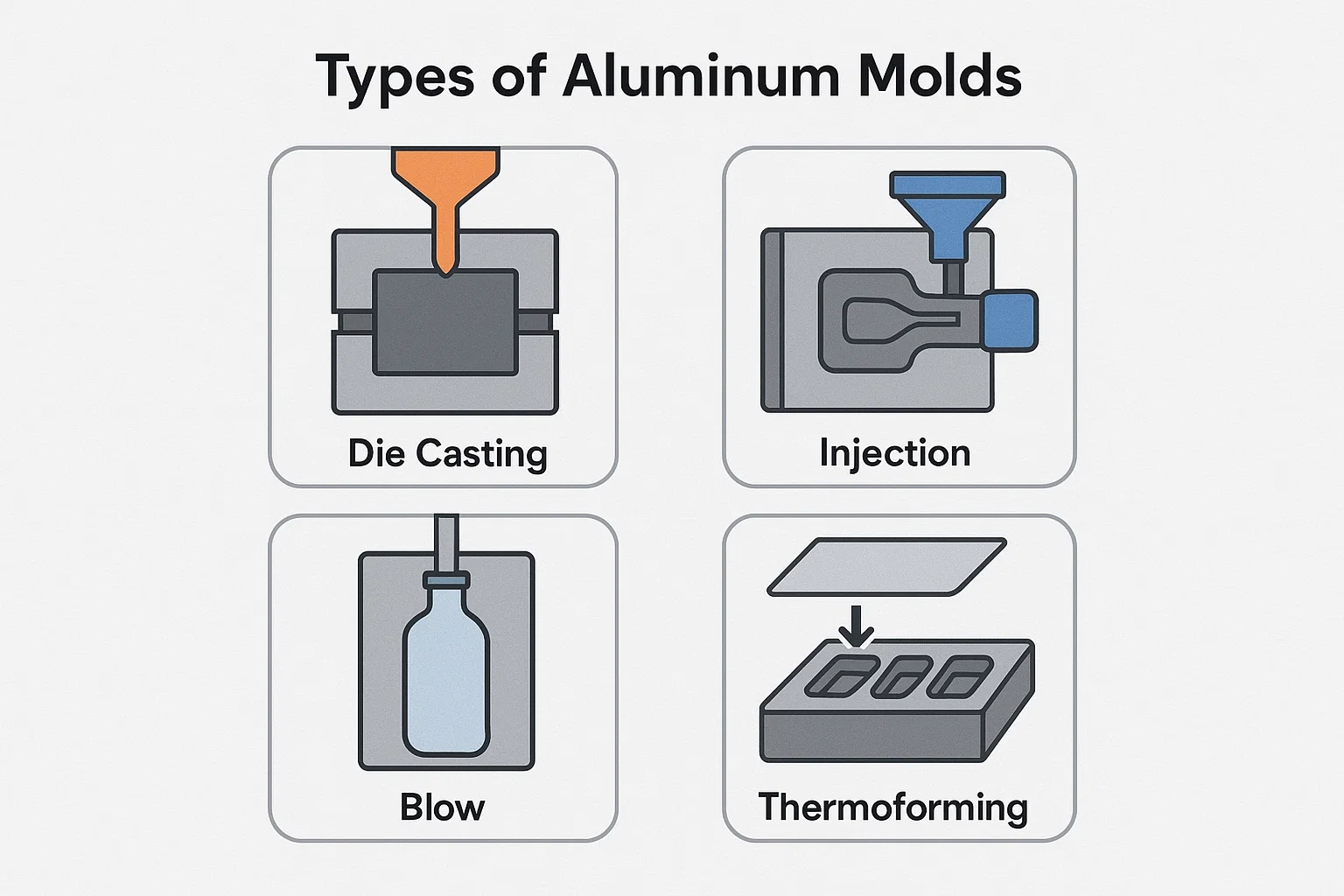

Based on Manufacturing Process

Die Casting Molds: Die casting is a process that forces molten metal under high pressure into a mold cavity. Aluminum is a popular material for the finished parts in die casting (e.g., engine blocks, camera bodies), but it can also be used to create the mold itself, particularly for prototyping and short-run production. Aluminum's excellent thermal conductivity helps to rapidly cool the molten metal, increasing the speed of the casting cycle.

Injection Molds: This is perhaps the most common application for aluminum molds. Injection molding involves injecting molten plastic into a mold under high pressure. Aluminum's standout feature here is its ability to dissipate heat quickly. This means the plastic solidifies faster, dramatically shortening the "cycle time" – the time it takes to produce one part. For a manufacturer, a faster cycle time translates directly into higher production efficiency and lower costs.

Blow Molds: Blow molding is a process used to create hollow plastic parts, like bottles and containers. It involves inflating a heated plastic tube (a parison) inside a closed mold. Aluminum molds are ideal for blow molding due to their lightweight nature, which makes them easier to handle and install, and their thermal properties, which help to evenly cool the plastic part, ensuring a consistent wall thickness.

Thermoforming Molds: Thermoforming is a process where a sheet of plastic is heated until pliable, then draped over or pressed into a mold. A vacuum is often applied to suck the sheet into the mold's contours. Aluminum's high thermal conductivity is crucial here, as it allows the mold to quickly heat or cool the plastic sheet, ensuring the final part holds its shape with precision. These molds are common in packaging, especially for food and consumer goods.

Based on Application

Plastic Molds: This broad category encompasses a huge variety of products, from children's toys and household items to complex electronic casings. As mentioned, aluminum is particularly effective for molding plastics due to its thermal properties and easy machinability, making it the material of choice for rapid prototyping and moderate-volume production.

Rubber Molds: Aluminum molds are also used to shape rubber, often through compression molding or injection molding. The ease with which aluminum can be machined allows for the creation of intricate mold cavities for products like gaskets, seals, and specialized rubber components.

Foam Molds: In industries like automotive and packaging, foam is molded to create insulation, seating components, and protective inserts. Aluminum molds are a great fit for this application because their lower weight and excellent thermal properties help in the delicate process of expanding and solidifying foam materials.

Food Molds: From chocolate bars to frozen desserts, aluminum molds are a staple in the food industry. Their corrosion resistance and ability to quickly transfer heat (or cold) are invaluable for ensuring consistent quality and speeding up production cycles. The material is also non-toxic and easy to clean, meeting strict hygiene standards.

Investment Casting Molds: While less common than for other processes, aluminum molds can be used as a "master" pattern for creating wax patterns in the investment casting process. This allows for the production of a large number of detailed wax patterns, which are then used to create ceramic molds for metal casting. The aluminum mold's durability and ability to capture fine details make it a good fit for this specific application.

Applications of Aluminum Molds

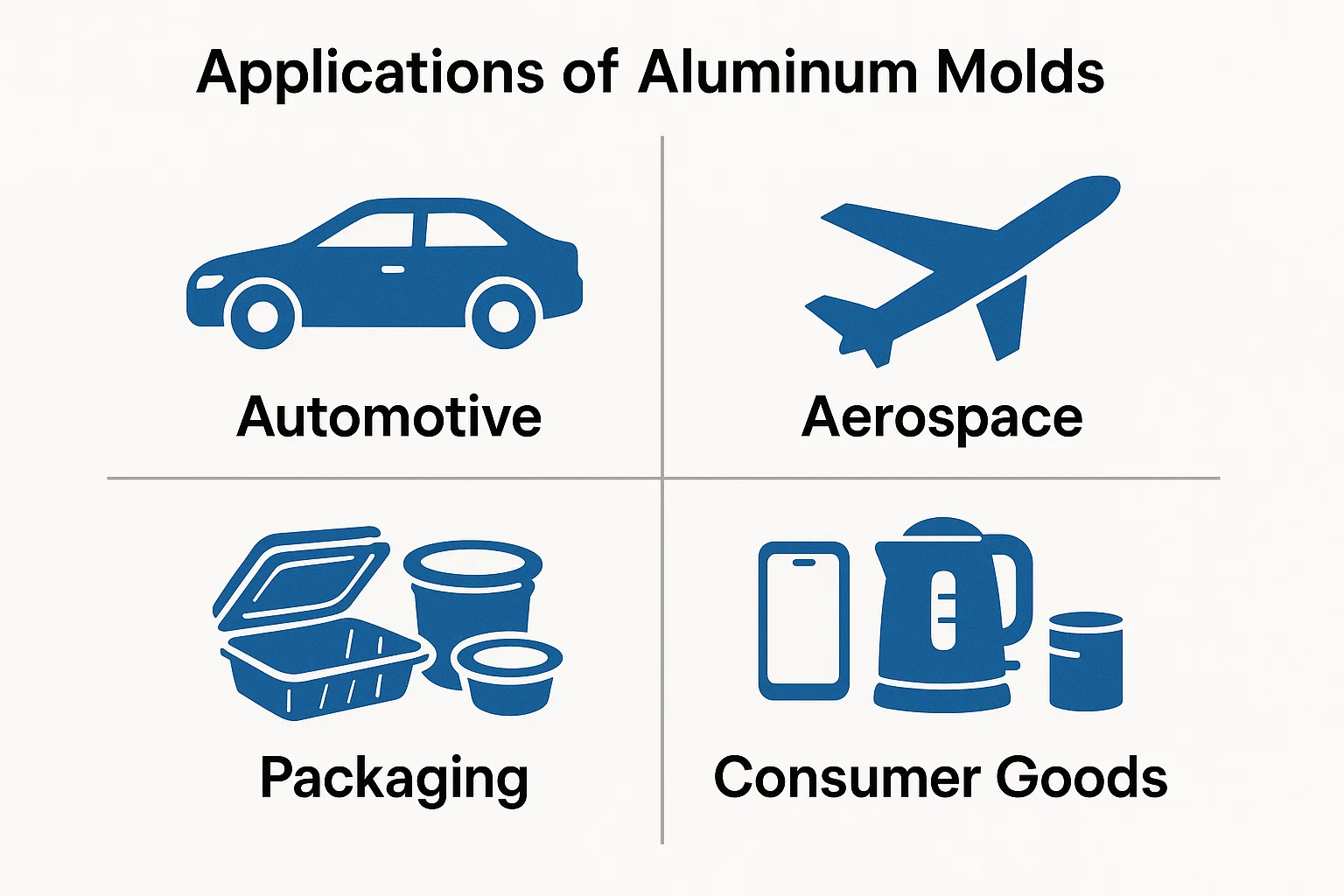

Aluminum molds have found their way into a diverse range of industries, driven by the need for faster, more cost-effective, and adaptable manufacturing processes. Their unique properties make them a preferred choice for companies looking to streamline production and bring new products to market quickly.

Industries Using Aluminum Molds

Automotive The automotive industry is a major user of aluminum molds, particularly for prototyping and low-volume production of interior components. Aluminum's ability to create complex shapes with a high degree of precision is crucial for parts like dashboards, door panels, and trim pieces. Furthermore, its rapid heat dissipation helps reduce the cycle time for molding plastic parts, which is a significant advantage in the fast-paced development cycles of new vehicle models.

Aerospace In the aerospace sector, where precision and weight are paramount, aluminum molds are used to create non-structural parts and components for both aircraft interiors and exteriors. Their lightweight nature simplifies handling during the molding process, and their cost-effectiveness makes them ideal for the production of specialized parts in smaller quantities.

Packaging Walk into any grocery store, and you'll see countless examples of products made with the help of aluminum molds. From plastic food containers and bottle caps to blister packs and consumer goods packaging, aluminum's quick cooling properties allow for mass production at high speeds. This efficiency is critical in the packaging industry, where millions of units are produced daily.

Consumer Goods The consumer goods market is driven by innovation and rapid product cycles. . Aluminum molds are a perfect fit, enabling manufacturers to quickly prototype and produce a wide array of products, including electronic device casings, appliance parts, and household items. The lower cost of aluminum molds compared to steel makes it feasible to produce molds for products with a shorter market lifespan or for limited edition runs.

Medical The medical industry relies on precision and sterility for a vast range of products, including diagnostic device housings, surgical tool handles, and single-use medical equipment. Aluminum molds are used to produce these items, offering the necessary accuracy and the ability to work with a variety of specialized plastic resins. The material's corrosion resistance also makes it suitable for sterile environments and repeated cleaning.

Benefits and Disadvantages of Using Aluminum Molds

While aluminum has a clear place in modern manufacturing, a balanced perspective requires understanding both its advantages and its limitations. The decision to use an aluminum mold often comes down to a careful weighing of these factors against a project's specific requirements.

Advantages of Aluminum Molds

High Thermal Conductivity This is perhaps the most significant benefit of aluminum molds. Aluminum conducts heat up to five times better than steel. In processes like injection molding, this means the molten material cools and solidifies much faster, dramatically reducing the overall cycle time. This efficiency directly translates to higher production output and lower per-part costs.

Lightweight Aluminum is approximately one-third the weight of steel. This makes aluminum molds easier to handle, move, and install in machinery, reducing strain on equipment and speeding up mold changeovers. The lower weight can also contribute to reduced energy consumption during the molding process.

Corrosion Resistance Unlike many types of steel, aluminum alloys used in mold making, such as 7075, have excellent natural resistance to corrosion. This property is crucial in environments where the molds may be exposed to moisture or certain chemicals, extending their lifespan and reducing maintenance needs.

Easy Machinability Aluminum is a softer metal than steel, making it much easier and faster to machine. A complex mold cavity that might take 100 hours to machine in steel could be completed in as little as 40 hours in aluminum. This ease of machining is a major factor in the cost-effectiveness and rapid turnaround times associated with aluminum molds, making them perfect for rapid prototyping and iterating on designs.

Cost-Effectiveness Due to its lower material cost and the reduced machining time, an aluminum mold can be significantly cheaper to produce than a comparable steel mold. This makes it an attractive option for projects with limited budgets or for production runs that don't require the extreme durability of steel.

Disadvantages of Aluminum Molds

Durability (compared to steel) The primary drawback of aluminum is its lower hardness compared to steel. While aluminum molds are strong enough for thousands of cycles, they will wear out faster than a hardened steel mold, especially when molding abrasive materials like glass-filled plastics. This makes them less suitable for ultra-high-volume production (e.g., millions of parts).

Wear Resistance The surface of an aluminum mold is more susceptible to scratching, dinging, and general wear and tear than a steel mold. This can impact the surface finish of the final product over time. However, this disadvantage can be mitigated by applying special surface treatments or coatings to the mold.

How to Choose the Right Aluminum Mold

Selecting the right mold for a project is a strategic decision that can significantly impact both the budget and the final product's quality. While aluminum offers many advantages, it isn't a one-size-fits-all solution. Here are the key factors to consider when deciding if an aluminum mold is the right choice for your project.

Factors to Consider

Production Volume This is often the most important factor. If your project requires a low to medium production run (typically from a few hundred to 50,000 parts), an aluminum mold is likely the most cost-effective and efficient choice. For high-volume production, where millions of cycles are needed, the superior durability and wear resistance of steel molds make them a better investment in the long run.

Part Complexity The complexity of the part design plays a major role. Aluminum's easy machinability allows for the creation of intricate and highly detailed mold cavities with less effort and time than steel. If your part has complex geometries, fine textures, or intricate features, an aluminum mold can provide a faster and more economical way to achieve the desired result.

Material Compatibility The material you plan to mold is critical. Aluminum molds are perfect for most commodity plastics like ABS, PP, and HDPE. However, if you are molding abrasive materials such as glass-filled nylon or materials that require very high processing temperatures, the mold will experience accelerated wear. In such cases, a more durable material like steel or a surface-treated aluminum mold may be necessary.

Budget For projects with a limited budget, aluminum molds are an attractive option. The lower material cost and reduced machining time translate into a lower upfront investment. This makes them ideal for startups, R&D projects, and anyone looking to test a new product on the market without committing a large amount of capital to tooling.

Part 6: Maintenance and Care of Aluminum Molds

Proper maintenance is crucial for extending the life of any mold, and aluminum molds are no exception. While they are more susceptible to wear than steel, a consistent care regimen can ensure they continue to produce high-quality parts for thousands of cycles.

Cleaning Procedures

Regular cleaning is essential to prevent the buildup of plastic residue, release agents, or other contaminants that can affect part quality.

-

Gentle Cleaning Agents: Use non-abrasive cleaners specifically designed for mold maintenance. Harsh chemicals or solvents can damage the mold surface and any protective coatings.

-

Soft Tools: Avoid using metal scrapers or wire brushes. Instead, use brass or plastic brushes, cotton swabs, and soft cloths to clean the mold surfaces without scratching them.

-

Preventative Sprays: Apply a thin, even coat of a high-quality mold release spray before each production run. This not only aids in part ejection but also acts as a protective layer, making future cleaning easier.

Storage Guidelines

When a mold is not in use, proper storage is key to preventing rust, corrosion, and physical damage.

-

Clean and Dry: Ensure the mold is completely clean and dry before storing it. Any moisture can lead to oxidation.

-

Protective Coating: Apply a rust preventative or a specialized mold protector spray to all surfaces of the mold. This creates a barrier against environmental elements.

-

Climate-Controlled Environment: Store molds in a climate-controlled area to avoid temperature fluctuations that can cause condensation.

-

Proper Casing: Store the mold in a sturdy, sealed container or on a designated shelf to prevent physical damage from accidental bumps or drops.

Preventative Maintenance Tips

Being proactive with maintenance can save you from costly repairs down the line.

-

Regular Inspections: Routinely inspect the mold for signs of wear, such as scratches, nicks, or erosion in critical areas like gates and runners. Catching these issues early allows for minor repairs before they become major problems.

-

Ejector Pin Checks: Regularly check that all ejector pins are moving freely and are not sticking, as this can cause stress on the mold and damage the finished part.

-

Lubrication: Keep moving parts, such as guide pins and bushings, properly lubricated to ensure smooth operation and prevent wear.

Future Trends in Aluminum Molds

The world of manufacturing is in a constant state of evolution, and aluminum molds are at the forefront of this change. Advancements in technology and a growing demand for faster production cycles are shaping the future of aluminum tooling.

Advancements in Manufacturing Techniques

The integration of Additive Manufacturing (3D Printing) is revolutionizing how aluminum molds are made. While a complete mold may still be CNC machined, 3D printing can be used to create complex internal features, such as conformal cooling channels. These channels follow the exact contours of the mold cavity, allowing for more uniform and rapid cooling of the part, which further reduces cycle times and improves part quality.

Another key trend is the use of Hybrid Molds, where an aluminum base is combined with hardened steel inserts in areas of high wear, such as gates and ejector pins. This clever design leverages the best of both worlds: the cost-effectiveness and rapid thermal properties of aluminum with the durability of steel in critical areas.

New Applications

As new high-performance aluminum alloys are developed, the use of aluminum molds will expand into industries that previously relied solely on steel. We can expect to see them used more frequently in applications involving stronger, more abrasive materials or in fields like electric vehicle manufacturing, where rapid prototyping and quick design iterations are essential for a competitive edge.

So

Aluminum molds have cemented their place as a vital component of modern manufacturing. They offer a compelling blend of cost-effectiveness, speed, and design flexibility that is unmatched by traditional tooling materials. While they may not be the ideal choice for every project, their exceptional thermal conductivity, lightweight nature, and ease of machining make them the go-to solution for prototyping, low-to-mid volume production, and products with complex geometries.

In an era defined by rapid innovation, the ability to quickly and economically transform an idea into a tangible product is more valuable than ever. Aluminum molds provide that crucial bridge between design and reality, empowering manufacturers to bring products to market faster and more efficiently. They represent not just a material choice, but a strategic decision that drives efficiency, innovation, and profitability across diverse industries.

Frequently Asked Questions (FAQs)

1. What is the main difference between aluminum and steel molds?

-

Answer: The primary differences are in cost, durability, and thermal properties. Aluminum molds are generally more affordable, lighter, and have much higher thermal conductivity, which shortens cycle times. However, steel molds are more durable and have a higher wear resistance, making them better for very high-volume production or molding abrasive materials.

2. How many parts can an aluminum mold produce?

-

Answer: The lifespan of an aluminum mold varies widely depending on the material being molded, part complexity, and maintenance. Aluminum molds are typically used for production runs ranging from a few hundred to tens of thousands of parts. With proper care and a non-abrasive material, some aluminum molds can even exceed 100,000 cycles.

3. Are aluminum molds suitable for injection molding?

-

Answer: Yes, absolutely. Aluminum molds are widely used in injection molding, especially for prototyping, low-volume production, and products with a non-abrasive plastic. Their high thermal conductivity allows for faster cooling of the plastic, which can significantly reduce the overall cycle time.

4. Can you use aluminum molds for high-temperature applications?

-

Answer: Aluminum alloys have a lower melting point than steel, so they are not suitable for extremely high-temperature molding processes like those used for certain engineering plastics. However, for most common plastics and rubber, aluminum molds perform exceptionally well.

5. What is the typical cost of an aluminum mold compared to a steel mold?

-

Answer: An aluminum mold can often be 30% to 50% less expensive than a comparable steel mold. This is primarily due to the lower material cost of aluminum and the reduced machining time required to create the mold.

English

English bahasa Indonesia

bahasa Indonesia