Introduction

In manufacturing, the right mold is crucial for creating high-quality parts. The material you choose for that mold directly impacts everything from cost and production speed to the final product's quality. While many materials are available, two stand out as the most common and versatile: aluminum and steel.

This article dives into the world of aluminum and steel molds, exploring their unique properties, advantages, and disadvantages. We'll compare them across key factors like cost, durability, and performance to help you understand which material is the best fit for your specific project.

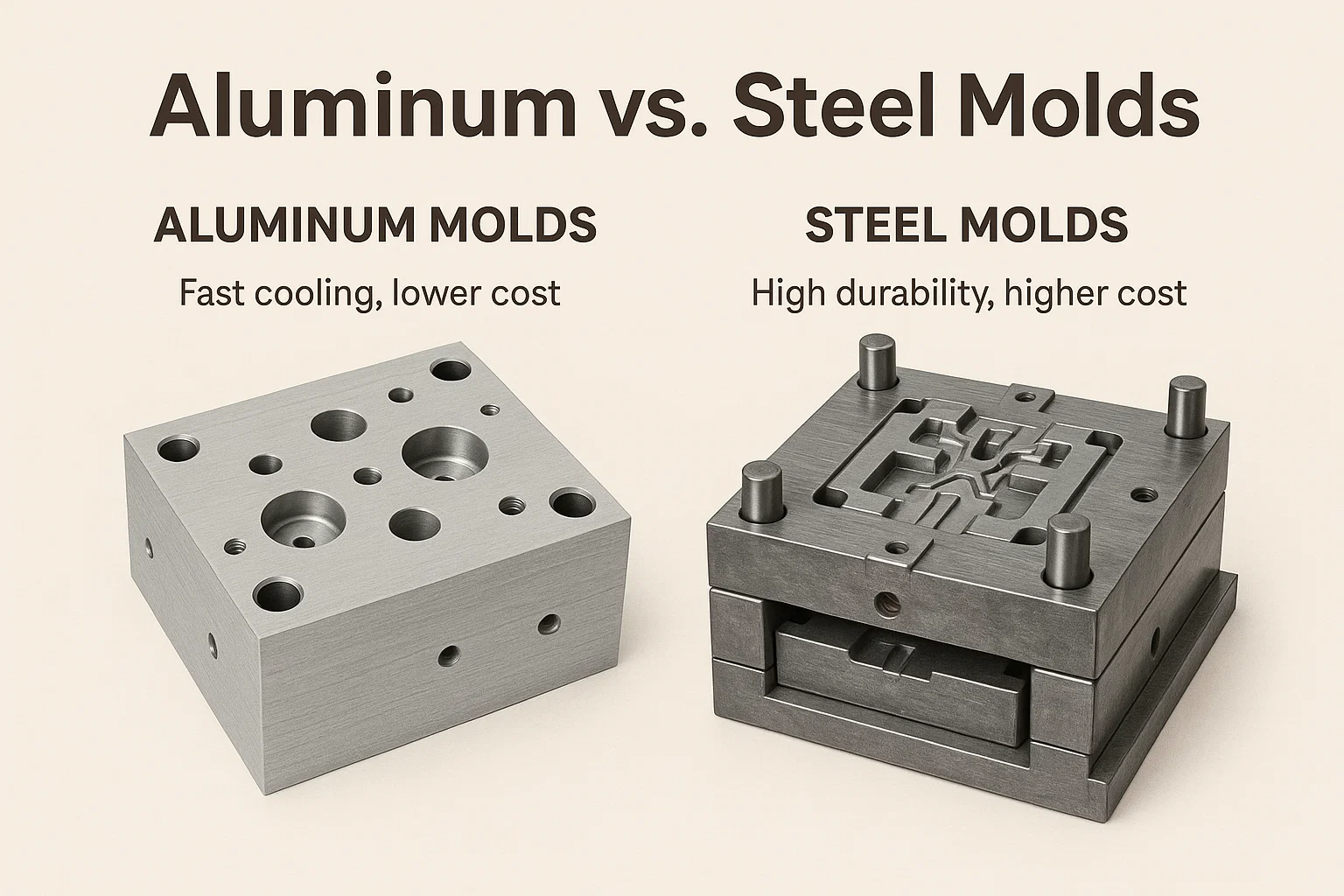

What are Aluminum Molds?

Aluminum molds are a popular choice for their unique balance of speed and efficiency. These molds are typically made from high-strength aluminum alloys, such as 7075 and 6061, which are known for their excellent machinability and high thermal conductivity.

Unlike steel, aluminum can dissipate heat very quickly. This makes it ideal for applications where rapid cooling is essential, such as prototyping or low-volume production runs. Because of their fast cycle times and lower machining costs, aluminum molds are often the go-to solution for projects that don't require the extreme durability of steel.

What are Steel Molds?

Steel molds are the industry standard for high-volume and demanding production. They are crafted from various grades of tool steel, with common types including P20, H13, and 420 stainless steel. These materials are valued for their exceptional hardness, wear resistance, and ability to hold precise dimensions.

Steel molds are built to last. They can withstand the rigors of millions of cycles, making them the most reliable choice for mass production. While they take longer to machine and cool compared to aluminum, their long-term durability and resistance to abrasion make them essential for producing parts with abrasive plastics or for operations that run continuously over many years.

Key Differences Between Aluminum and Steel Molds

When choosing between aluminum and steel, the decision comes down to a few critical differences that impact production.

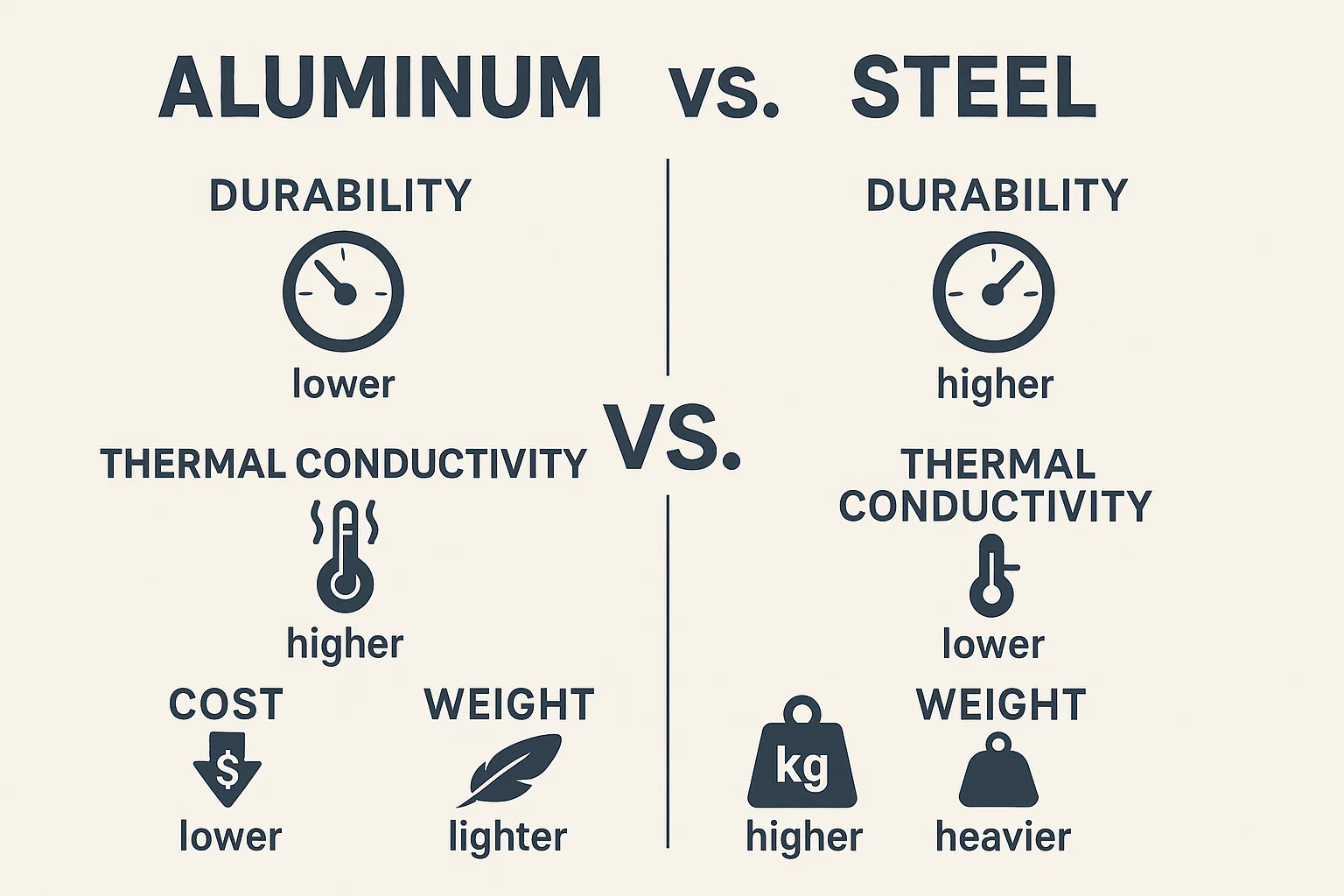

Durability and Lifespan

Steel molds are the undisputed champions of durability. Built to endure millions of cycles, they resist wear, abrasion, and corrosion, making them perfect for high-volume manufacturing. Aluminum molds, while strong, are softer. They wear down faster and are best suited for shorter production runs, typically under 100,000 parts, unless they are treated with special coatings to extend their life.

Thermal Conductivity

This is where aluminum molds truly shine. Aluminum transfers heat up to five times faster than steel. This high thermal conductivity means the mold cools down significantly faster, which dramatically reduces cycle times and increases production speed. Steel molds, in contrast, retain heat longer, leading to slower cooling and a longer overall cycle time.

Cost Analysis

The cost difference is significant. The initial material for aluminum is cheaper, and its excellent machinability means it requires less time and energy to manufacture into a finished mold. This makes aluminum a highly cost-effective choice for prototypes and low-volume projects. Steel, however, is more expensive to buy and much harder to machine, leading to higher upfront costs. While the initial investment is higher, the long-term operational cost per part is lower for high-volume production due to its incredible longevity.

Weight

Aluminum is much lighter than steel—roughly a third of the weight. This makes aluminum molds easier and safer to handle, transport, and set up. The reduced weight also puts less strain on the molding machine, potentially allowing for the use of smaller presses. Steel molds are heavy and cumbersome, often requiring specialized equipment for handling and installation.

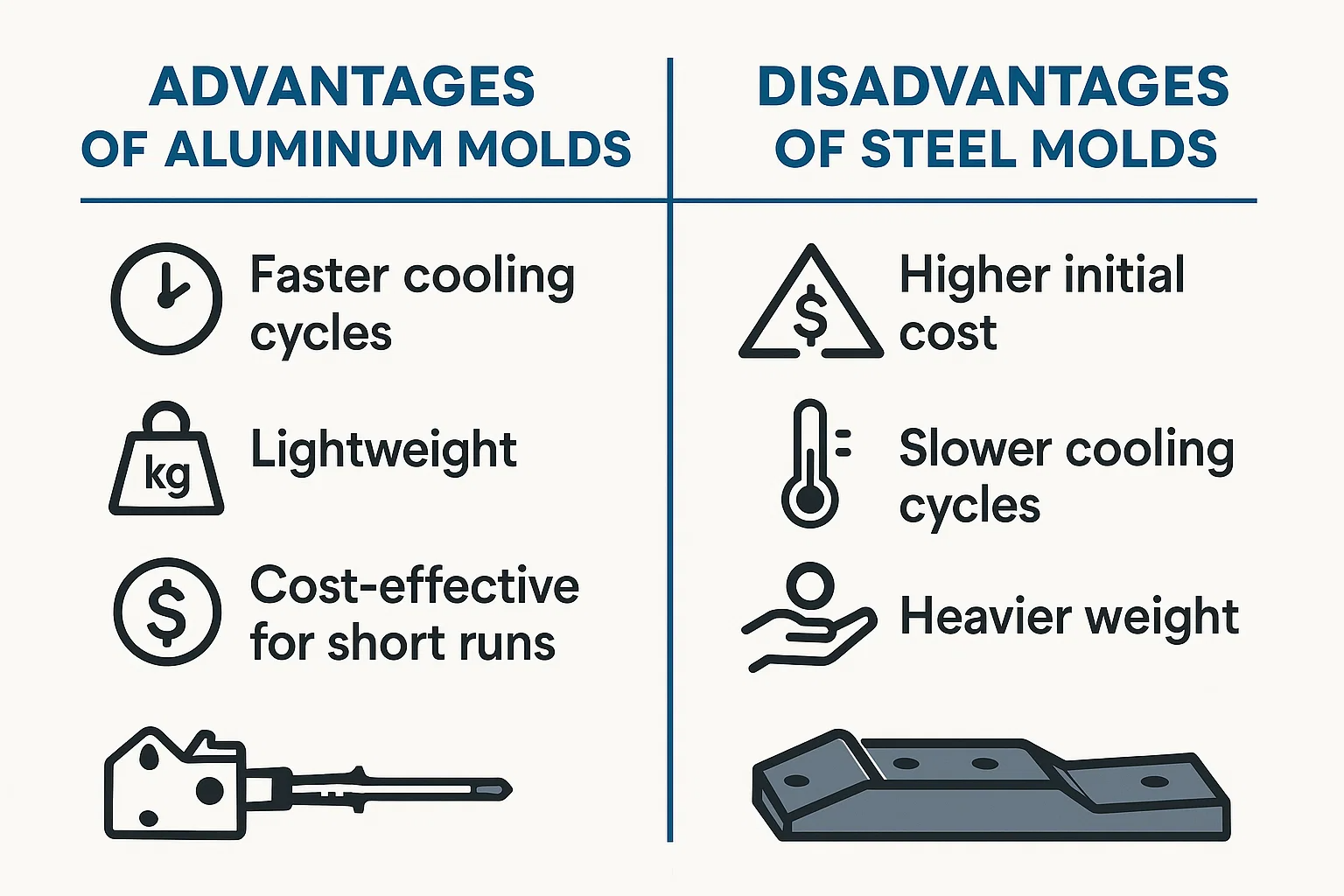

Advantages of Aluminum Molds

-

Faster Cooling Cycles: Aluminum's high thermal conductivity means it pulls heat away from the part quickly. This drastically cuts down on cooling time, leading to faster production cycles and higher output per hour.

-

Lightweight: Being significantly lighter than steel, aluminum molds are easier to handle, transport, and install. This not only improves safety but also reduces wear and tear on molding machinery, potentially allowing for the use of smaller, more energy-efficient presses.

-

Cost-Effective for Short Runs: The lower material cost and easier machinability of aluminum make it an excellent choice for prototyping and low-volume production. You can get a mold made quickly and at a lower upfront cost, making it ideal for testing designs or producing limited runs.

Disadvantages of Aluminum Molds

-

Lower Durability: Aluminum is softer than steel and cannot withstand the millions of cycles required for mass production. It's more susceptible to dings, scratches, and wear over time, which limits its lifespan.

-

Susceptibility to Wear: Without a protective coating, aluminum molds can wear out quickly, especially when molding abrasive materials like glass-filled plastics.

-

Less Suitable for Abrasive Materials: For materials that are highly abrasive, a steel mold is almost always required. The softer surface of an aluminum mold would degrade too quickly, compromising part quality and requiring frequent repairs.

Advantages of Steel Molds

-

High Durability and Lifespan: Steel is incredibly tough. Molds made from tool steel are designed to withstand constant use, making them perfect for high-volume production runs that can last for years.

-

Resistance to Wear and Abrasion: The hardness of steel makes it highly resistant to abrasion from filled plastics or other tough materials. This ensures the mold maintains its dimensional accuracy and surface finish over millions of parts.

-

Dimensional Stability: Steel holds its shape and size under pressure and temperature changes better than aluminum. This stability is critical for producing parts with tight tolerances and complex geometries.

Disadvantages of Steel Molds

-

Higher Initial Cost: The raw material for steel molds is more expensive, and the machining process is much slower and more labor-intensive. This results in a higher upfront investment and longer lead times.

-

Slower Cooling Cycles: Steel's lower thermal conductivity means it retains heat longer. This extends the cooling time for each part, leading to slower production cycles and reduced output compared to an aluminum mold.

-

Heavier Weight: The sheer weight of a steel mold can make it difficult to handle and transport. It also requires a more robust molding machine, which can increase operational costs and limit flexibility.

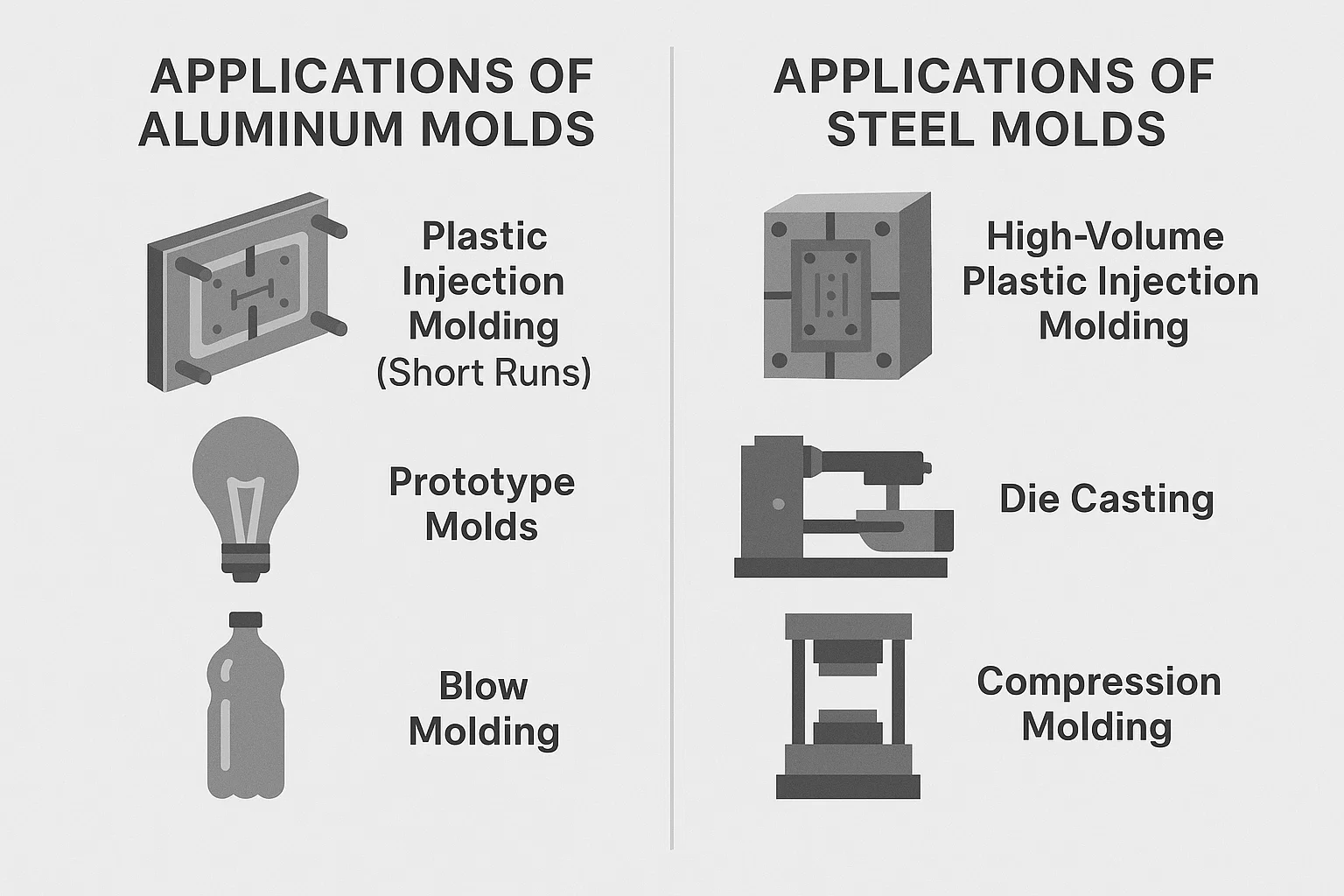

Applications of Aluminum Molds

-

Plastic Injection Molding (Short Runs): Aluminum is perfect for projects where you need a limited number of parts, from a few hundred to tens of thousands. Its fast cycle times make it a go-to for quick turnaround jobs and initial market testing.

-

Prototype Molds: When you need to create functional prototypes for a new product, aluminum is the clear winner. The low cost and rapid machining allow engineers to iterate on designs quickly and affordably.

-

Blow Molding: In industries like packaging and container manufacturing, where cooling is the limiting factor, aluminum's superior thermal properties are a huge advantage. It helps create uniform walls and consistent part quality faster.

Applications of Steel Molds

-

High-Volume Plastic Injection Molding: For large-scale production, where millions of parts are needed, steel is the only viable option. Its durability ensures the mold can run continuously for years without significant wear.

-

Die Casting: In die casting, molten metal is injected into a mold at high pressure. Steel's strength and heat resistance make it ideal for handling the extreme temperatures and forces involved in casting materials like aluminum, zinc, and magnesium.

-

Compression Molding: When molding thermoset materials or composites, high pressure and temperature are required. Steel's robust nature makes it the best choice for withstanding these demanding conditions, ensuring the mold doesn't deform over time.

Case Studies: Aluminum vs. Steel Mold Selection

The choice between aluminum and steel is often a balance of trade-offs. Here are two examples:

-

Case Study 1 (Aluminum): The Consumer Electronics Prototype A tech company needed to create 5,000 units of a new gadget casing for a market test. They chose an aluminum mold. The primary decision factors were a tight deadline and a limited budget. Aluminum allowed them to machine the mold quickly and at a fraction of the cost of steel. The mold's lower durability wasn't an issue since the production run was short, and the faster cycle times helped them meet the launch date.

-

Case Study 2 (Steel): The Medical Device Component A medical device manufacturer required a critical component to be produced in the millions. The part had to be dimensionally perfect and made from a highly abrasive, glass-filled plastic. They opted for a steel mold. Despite the higher initial cost and longer lead time, the decision was based on steel's unmatched durability and ability to resist abrasion. The long-term reliability and precision were non-negotiable for this high-volume, mission-critical application.

Factors to Consider When Choosing a Mold Material

-

Production Volume: This is the most important factor. For low-volume runs and prototypes, aluminum is the most cost-effective solution. For high-volume, mass production, the durability and lifespan of steel are essential.

-

Material Being Molded: If you're working with abrasive plastics (like those with glass or carbon fiber fillers), steel's wear resistance is a necessity. For non-abrasive polymers, aluminum can be a viable and faster alternative.

-

Part Complexity: For parts with intricate details or tight tolerances, the dimensional stability of steel often provides a more reliable and precise outcome. While aluminum can achieve high detail, it is more susceptible to pressure-related deformation.

-

Budget: Consider both the initial cost and the long-term operational costs. An aluminum mold has a lower upfront price but may have a higher cost-per-part over time if it needs to be replaced. A steel mold has a high initial investment but a very low long-term cost per part.

-

Cycle Time Requirements: If your project demands the fastest possible production speed, aluminum's superior thermal conductivity and faster cycle times can be a game-changer.

Best Practices for Mold Maintenance

Regardless of whether you use aluminum or steel, proper maintenance is key to extending the life of your mold and ensuring part quality.

-

Cleaning and Storage: After each production run, molds should be thoroughly cleaned to remove any residue. Proper storage in a climate-controlled environment prevents rust and corrosion, especially for steel molds.

-

Regular Inspection: Routinely inspect the mold for signs of wear, damage, or buildup. Catching issues early can prevent more costly repairs down the line. Look for scratches, dents, or signs of flash.

-

Lubrication and Corrosion Prevention: Apply a light coat of a non-damaging lubricant or corrosion inhibitor, particularly to moving parts like ejector pins and slides. This prevents seizing and rust, ensuring smooth operation.

Future Trends in Mold Materials

The world of mold making is always evolving, with new materials and technologies on the horizon.

-

Advancements in Aluminum Alloys: Researchers are developing new aluminum alloys with enhanced hardness and wear resistance, blurring the line between aluminum and steel for some applications.

-

Developments in Tool Steel Technology: Innovations in steel are focused on creating grades that are easier to machine and offer improved thermal conductivity without sacrificing durability. Additive manufacturing (3D printing) is also being used to create complex steel molds with internal cooling channels.

-

Emerging Materials: Other materials are gaining attention. Beryllium copper, for example, offers exceptional thermal conductivity, making it an excellent choice for mold inserts that require rapid heat dissipation in specific areas.

English

English bahasa Indonesia

bahasa Indonesia