I. Definition and Manifestations of Stress Marks

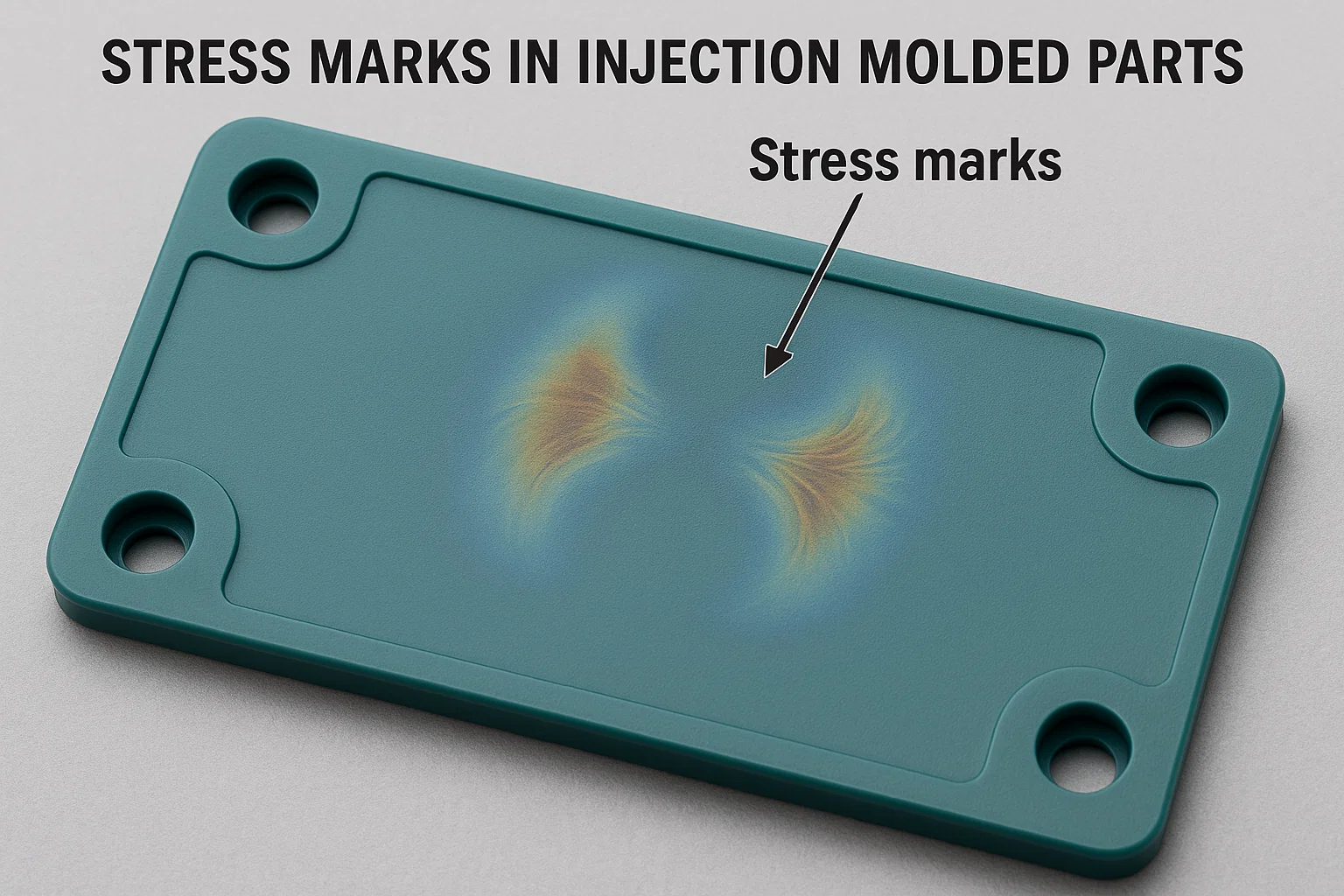

Stress marks in injection molded parts are surface defects caused by localized stress concentration, appearing as glossy or uneven texture. Common locations include:

- Visual Discrepancies: More noticeable on dark-colored parts, resembling "ghost lines" or uneven shading.

- Positional Features: Often occur near flow ends, weld lines, and areas with uneven cooling.

II. Root Cause Analysis

1. Mold Design Flaws

- Improper Gate Design: Small gates or poor placement lead to high shear rates and temperature gradients.

- Abrupt Wall Thickness Changes: Thickness variations exceeding 30% cause uneven shrinkage (e.g., thin-walled areas restrict contraction, generating tensile stress).

- Inadequate Venting: Gas traps at parting lines or flow ends create localized overheating and flow turbulence.

- Sharp Corners and Rib Design: High flow resistance at sharp angles; ribs thicker than 40%-60% of the main wall thickness disrupt cooling uniformity.

2. Process Parameter Issues

- Excessive Injection Speed/Pressure: High shear stress and molecular orientation increase residual stress.

- Temperature Mismanagement: Low melt temperature or uneven mold cooling (e.g., poorly designed cooling channels) amplifies shrinkage differences.

- Insufficient Packing Pressure: Short packing time or low pressure fails to compensate for shrinkage, causing sink marks and stress marks in thick sections.

3. Material Characteristics

- High Melt Flow Index (MFI): Excessively fluid materials promote molecular orientation and uneven shrinkage.

- Crystallinity Effects: Crystalline materials (e.g., PP, PA) are sensitive to cooling rates; thick-wall areas develop crystallinity disparities.

- Additive Segregation: Fillers like glass fibers accumulate at flow ends, weakening interfacial bonding.

4. Product Design Limitations

- Non-Uniform Wall Thickness: Examples include laptop back covers with 40%-60% thickness variations.

- Poor Weld Line Placement: Stress marks form when weld lines coincide with cosmetic surfaces.

III. Comprehensive Solutions

1. Mold Design Optimization

- Gate Modifications: Enlarge gates (e.g., 1.5mm → 2.0mm); adopt fan or overlap gates to reduce shear.

- Gradual Thickness Transitions: Add radii (≥0.5× wall thickness) at abrupt changes; case studies show 80% stress mark reduction.

- Enhanced Venting: Add vent slots (0.02-0.04mm depth) at flow ends; use porous steel or insert vents.

- Conformal Cooling: Implement conformal cooling channels to limit temperature variation to ±5°C.

2. Process Adjustments

- Temperature Control: Raise melt temperature by 10-20°C (e.g., PA66: 270°C → 290°C) and mold temperature by 20-30°C (e.g., ABS: 60°C → 80°C).

- Multi-Stage Injection: Start with low speed (30%-50% max) for initial filling, then switch to high speed; set packing pressure at 70%-90% injection pressure.

- Extended Packing Time: Increase from 2s to 4s to mitigate shrinkage and residual stress.

3. Material Modifications

- Low-Shrinkage Materials: Add 30% talc to PP, reducing shrinkage from 1.8% to 0.8%.

- Flow Additives: 0.1%-0.5% silicone-based lubricants lower melt viscosity by 10%-20%.

- Fiber Compatibility: Treat glass fibers with coupling agents to minimize interfacial stress.

4. Post-Processing & Testing

- Annealing: PC parts annealed at 120°C for 2 hours eliminate 60%-80% internal stress.

- Stress Detection: Use polarized light or solvent immersion (e.g., ABS in glacial acetic acid for 2 minutes) for qualitative analysis.

IV. Case Studies

Case 1: Toy Gun Stock Stress Marks

- Issue: PP+10%GF part showed stress marks on ribs (50% thickness difference).

- Fix: Reduce rib thickness to 40% of main wall; add radii; lower packing pressure (80MPa → 60MPa); raise mold temp (60°C → 80°C).

- Result: 100% elimination; yield increased from 70% to 95%.

Case 2: Laptop Cover Stress Marks

- Issue: PC+ABS part had stress marks due to 0.9mm/1.5mm wall mismatch.

- Fix: Reposition gate to fill thick areas first; raise mold temp (90°C → 110°C); extend packing to 6s.

- Result: 90% reduction; 98% cosmetic pass rate.

V. Summary

Stress mark mitigation requires multidisciplinary optimization:

- Preventive Design: Limit wall thickness variation (≤20%); use radii and balanced runners.

- Precision Processing: Gradient temperature/pressure control with adequate packing.

- Material Selection: Prioritize low-shrinkage, high-flow materials; use modifiers as needed.

Systematic improvements enhance aesthetics, mechanical performance, and cost efficiency.

English

English bahasa Indonesia

bahasa Indonesia