Introduction

In the intricate world of modern manufacturing, product design often demands the integration of multiple materials or components into a single, cohesive unit. This not only enhances functionality and aesthetics but can also streamline assembly and reduce overall production costs. When it comes to plastic parts, three advanced injection molding techniques stand out for their ability to achieve this integration: insert molding, overmolding, and co-molding.

While all three processes leverage the fundamental principles of injection molding, they differ significantly in their methodology, material combinations, applications, and the benefits they offer. Understanding these distinctions is crucial for engineers, designers, and manufacturers alike to select the optimal process for their specific project requirements. A misstep in choosing the right technique can lead to material incompatibility issues, increased costs, compromised part performance, or complex secondary operations.

This comprehensive guide will delve into each of these sophisticated molding processes, explaining their unique characteristics, detailing the materials typically employed, exploring their diverse applications across industries, and outlining their respective advantages and disadvantages.

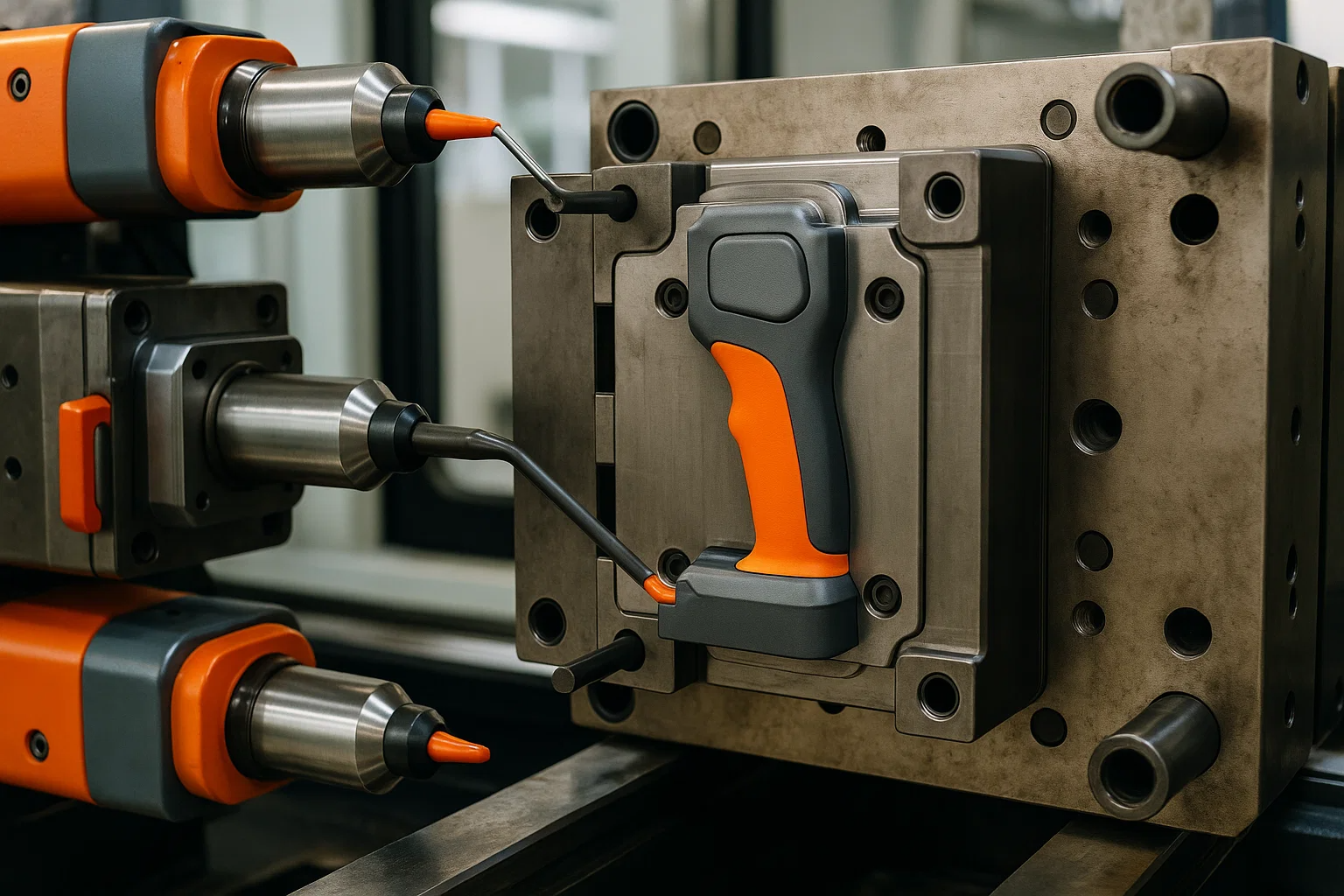

Insert Molding

Insert molding is a highly versatile injection molding process where pre-formed components, known as inserts, are placed into a mold cavity and then plastic material is injected around them. The molten plastic flows and solidifies, encapsulating or bonding with the insert, effectively creating a single, integrated part. The insert becomes an integral, functional, or structural element of the final molded product.

Process Overview

The insert molding process typically involves the following steps:

-

Insert Preparation: Inserts, which can be made of various materials like metal, ceramic, or even pre-molded plastic parts, are prepared. This might include cleaning, pre-heating, or applying an adhesive/primer if enhanced bonding is required.

-

Insert Placement: The prepared inserts are precisely positioned within the mold cavity. This can be done manually for low-volume production or, more commonly in high-volume settings, automatically using robotic arms, pick-and-place units, or specialized feeding systems to ensure accurate and repeatable placement.

-

Mold Clamping: Once the inserts are in place, the mold halves are securely clamped together.

-

Material Injection: Molten plastic (thermoplastic or thermoset) is injected under high pressure into the mold cavity, flowing around and encapsulating the inserts. The material fills all voids, creating a strong bond or mechanical lock with the insert.

-

Cooling and Solidification: The plastic material cools and solidifies around the insert, taking the shape of the mold cavity.

-

Ejection: The mold opens, and the finished part, with the integrated insert, is ejected.

Materials Commonly Used

Insert molding is compatible with a wide range of materials for both the insert and the overmolding material:

-

For Inserts:

-

Metals: Brass, stainless steel, aluminum, copper (e.g., threaded inserts, pins, contacts, shafts). These provide strength, conductivity, or wear resistance.

-

Plastics: Other pre-molded plastic components (e.g., filters, lenses, gears).

-

Ceramics: For specific electrical or thermal properties.

-

Glass: For lenses or optical components.

-

Electronic Components: PCBs, sensors, connectors.

-

-

For the Molded Material (Plastic):

-

Thermoplastics: ABS, PC, Nylon (PA), PBT, PP, PE, PEEK, PSU. The choice depends on the required strength, temperature resistance, chemical resistance, and aesthetic properties.

-

Thermosets: Less common but used for specific high-performance applications where heat resistance or chemical inertness is critical.

-

Applications

Insert molding is widely utilized across numerous industries for a variety of products:

-

Electronic Components: Connectors, switches, sensors, circuit board encapsulation, solenoids, terminal blocks, often integrating metal pins or leads into plastic housings.

-

Medical Devices: Surgical instruments (integrating metal blades or tips into plastic handles), diagnostic equipment components, fluid connectors, housings for electronic medical devices.

-

Automotive Parts: Bushings, bearings, gears, electronic housings, switches, dashboard components, often integrating metal inserts for durability or functionality.

-

Consumer Electronics: Buttons, knobs, handles, housings for handheld devices, incorporating metal contacts or structural elements.

-

Industrial Components: Impellers with metal hubs, control knobs with threaded inserts, filtration systems.

Advantages

-

Improved Part Strength and Durability: Metal inserts significantly enhance the structural integrity, wear resistance, and thread strength of plastic parts.

-

Reduced Assembly Time and Costs: By integrating multiple components into a single molding step, secondary assembly operations (like screwing, gluing, or welding) are eliminated or drastically reduced, leading to significant labor and cost savings.

-

Enhanced Functionality: Allows for the combination of properties from different materials (e.g., the strength of metal with the lightweight or insulative properties of plastic).

-

Compact Design: Enables the creation of smaller, more integrated parts, which is crucial for miniaturization in electronics and medical devices.

-

Cost-Effective for High-Volume Production: While initial tooling costs can be moderate, the efficiency gains in high-volume runs make it very economical.

Disadvantages

-

Potential for Insert Damage During Molding: Delicate or thin inserts can be bent, deformed, or damaged by the high pressure of the injected molten plastic.

-

Limited Design Flexibility (for Inserts): The design of the insert itself must be robust enough to withstand the molding process. Features that prevent rotation or pull-out (e.g., knurls, undercuts) must be incorporated into the insert design.

-

Insert Preparation and Placement Complexity: For complex or very small inserts, manual placement can be slow and expensive. Automated systems require significant initial investment and setup time.

-

Increased Tooling Complexity and Cost: Molds must be designed with features to precisely hold the inserts in place during injection, potentially increasing mold design and manufacturing costs compared to a simple injection mold.

-

Material Compatibility Considerations: Proper adhesion or mechanical lock between the insert and the plastic must be ensured to prevent loosening or delamination, especially under stress or temperature fluctuations.

Overmolding

Overmolding is an injection molding process where a layer of one material (the overmold material) is molded over an existing, pre-formed part (the substrate or first shot). This process creates a single, integrated component with distinct material properties on different surfaces, often enhancing aesthetics, ergonomics, or functionality. Unlike insert molding where the insert is a separate component, in overmolding, the substrate itself is typically a plastic part that has already been molded.

Process Overview

Overmolding can be achieved through various methods, but the core principle involves two or more distinct molding steps:

-

Substrate (First Shot) Molding: The base part, or substrate, is injection molded using a rigid material (e.g., ABS, PC, Nylon). This part is allowed to cool and solidify.

-

Substrate Transfer:

-

Two-Shot (Multi-Shot) Overmolding: In highly automated processes, the substrate part remains in the mold or is rotated to a second cavity within the same specialized multi-shot molding machine. This is the most efficient method for high-volume production.

-

Insert Overmolding (Manual or Robotic): For less complex geometries or lower volumes, the finished substrate part is manually or robotically transferred from one mold (or molding machine) to a second mold (or another cavity in the same machine) where the overmold material will be injected.

-

-

Overmold Material Injection: The second, often softer or more flexible, material (e.g., TPE, TPU) is then injected into the second cavity, flowing over and bonding to specific areas of the pre-molded substrate.

-

Cooling and Solidification: The overmold material cools and solidifies, forming a strong chemical or mechanical bond with the substrate.

-

Ejection: The finished, overmolded part is ejected from the mold.

Materials Commonly Used

The selection of materials is critical in overmolding to ensure proper adhesion, desired aesthetics, and functional performance.

-

For the Substrate (First Shot): Typically rigid thermoplastics that provide structural integrity. Common choices include:

-

ABS (Acrylonitrile Butadiene Styrene)

-

Polycarbonate (PC)

-

Nylon (PA)

-

Polypropylene (PP)

-

High-Density Polyethylene (HDPE)

-

Acrylic (PMMA)

-

-

For the Overmold (Second Shot): Often softer, elastomeric, or aesthetically distinct materials that bond well with the substrate. Common choices include:

-

Thermoplastic Elastomers (TPEs): A broad class including TPUs (Thermoplastic Polyurethanes), TPVs (Thermoplastic Vulcanizates), COPEs (Copolyester Elastomers), and others. These provide soft-touch, grip, sealing, or vibration damping properties.

-

Thermoplastic Polyurethanes (TPUs): Excellent abrasion resistance, elasticity, and good adhesion to many rigid plastics.

-

Softer Grades of Polypropylene (PP) or Polyethylene (PE): For applications requiring a different texture or color without the need for a rubber-like feel.

-

Other Plastics: Sometimes a second rigid plastic is overmolded for multi-color or multi-texture effects without a soft-touch requirement.

-

Applications

Overmolding is extensively used across various industries to add value, functionality, and appeal to products:

-

Soft-Touch Grips: Tool handles (power tools, hand tools), toothbrush handles, razor grips, sporting equipment, automotive interior grips, and consumer electronics casings where a comfortable, non-slip grip is desired.

-

Seals and Gaskets: Creating integrated seals on enclosures, caps, or electronic devices to provide water or dust resistance, eliminating the need for separate O-rings or gaskets.

-

Encapsulation and Protection: Protecting sensitive electronic components, medical instruments, or delicate mechanisms from impact, moisture, or chemicals.

-

Vibration Damping: Integrating softer materials to absorb shocks and vibrations in automotive parts, electronic devices, or appliance components.

-

Enhanced Aesthetics: Creating multi-colored or multi-textured parts for improved visual appeal, branding, or tactile differentiation (e.g., contrasting color buttons on a remote control).

-

Medical Devices: Surgical instrument handles, patient contact surfaces, and flexible tubing connectors.

Advantages

-

Enhanced Aesthetics and Ergonomics: Creates parts with improved tactile feel, comfortable grips, and multi-color/texture designs, significantly improving user experience and product appeal.

-

Improved Grip and Non-Slip Properties: Ideal for handles and surfaces that require a secure hold, even when wet.

-

Sealing Capabilities: Eliminates the need for separate gaskets or seals, reducing assembly steps and potential leak paths, leading to cost savings and improved performance.

-

Vibration and Shock Absorption: The softer overmold material can effectively dampen vibrations and absorb impact, protecting internal components.

-

Design Freedom: Allows for complex geometries and functional integration that would be difficult or impossible with single-shot molding.

-

Reduced Assembly Costs: By integrating multiple materials into a single process, secondary operations like gluing, fastening, or manual assembly of grips are minimized or eliminated.

Disadvantages

-

Material Compatibility Issues: Achieving a strong bond between the substrate and overmold material is critical. Incompatible materials can lead to delamination, warpage, or poor adhesion. Careful material selection and sometimes chemical bonding agents are necessary.

-

Potential for Delamination: If material compatibility or processing conditions are not optimized, the overmold layer can separate from the substrate, compromising the part's integrity.

-

More Complex Tooling: Overmolding tools are inherently more complex than single-shot molds, especially for two-shot systems, leading to higher initial tooling costs and longer lead times.

-

Longer Cycle Times (for some methods): While two-shot overmolding is efficient, methods involving manual transfer of parts can significantly increase cycle times compared to simple injection molding.

-

Shrinkage Differences: Different shrinkage rates between the substrate and overmold materials can lead to warpage or internal stresses in the final part.

-

Flash and Contamination Concerns: Ensuring clean transfer and preventing flash of the first material into the second cavity requires precise mold design and process control.

Co-molding (Multi-shot Molding)

Co-molding, often interchangeably referred to as multi-shot molding, two-shot molding, or multi-component injection molding, is an advanced manufacturing process that allows for the simultaneous or sequential injection of two or more different materials into a single mold within a single molding cycle. This technique produces highly integrated, multi-material parts, eliminating the need for separate assembly steps and enabling complex designs with varying material properties within a single component.

Process Overview

The core of co-molding lies in using specialized injection molding machines equipped with multiple injection units and often a rotating platen or core:

-

First Material Injection: The first material (e.g., a rigid plastic) is injected into a portion of the mold cavity to form the initial part or substrate.

-

Mold Reconfiguration/Rotation:

-

Rotating Platen/Core: In the most common two-shot systems, the mold core (or a platen containing multiple cavities) rotates to present the partially molded part to a second injection unit.

-

Core-Back/Sliding Core: In some systems, a sliding core or core-back mechanism shifts to create a new cavity for the second material, without rotating the entire mold.

-

-

Second Material Injection: While the first material is still in the mold (and sometimes still warm), the second material (e.g., a soft TPE, a different color plastic, or a different functional plastic) is injected into the newly formed or exposed cavity, bonding with the first material.

-

Subsequent Injections (for Multi-shot): For parts requiring three or more materials, this process repeats with additional injection units and mold reconfigurations.

-

Cooling and Solidification: All materials cool and solidify together within the single mold.

-

Ejection: The fully formed, multi-material part is ejected from the mold.

Types of Co-molding

While "co-molding" is a broad term, the most prominent types include:

-

Two-Shot Molding (2K Molding): This is the most prevalent form of co-molding, involving two different materials injected sequentially within the same machine and mold. It's widely used for creating parts with soft-touch grips, multi-color aesthetics, or integrated seals.

-

Multi-Component Molding: An extension of two-shot, involving three or more different materials. This requires more complex machinery and mold designs.

-

Co-Injection Molding: A distinct type where two (or more) materials are injectedsimultaneouslythrough the same gate, often creating a "sandwich" structure. For example, a core material (e.g., recycled plastic) is surrounded by a skin material (e.g., virgin plastic for aesthetics or specific properties). This is excellent for material savings or achieving unique material gradients.

-

Overmolding (as a form of Co-molding): While discussed separately due to its distinct application, overmolding, when performed on a multi-shot machine without removing the part, is technically a form of co-molding.

Materials Commonly Used

Co-molding allows for a vast array of material combinations, primarily thermoplastics and thermoplastic elastomers:

-

Thermoplastic-Thermoplastic Combinations:

-

Different Colors: E.g., rigid ABS in black with rigid ABS in white for multi-colored buttons or keycaps.

-

Different Stiffnesses: E.g., rigid Polycarbonate for a structural backbone with a slightly more flexible Nylon for a living hinge or snap-fit feature.

-

Different Properties: E.g., a clear acrylic for a lens with an opaque ABS for the housing.

-

-

Thermoplastic-Thermoplastic Elastomer (TPE) Combinations:

-

This is extremely common for soft-touch grips (e.g., rigid PC or ABS with soft TPE/TPU), integrated seals, or vibration-damping features.

-

-

Material Compatibility: The success of co-molding heavily relies on the chemical and physical compatibility between the chosen materials to ensure strong adhesion and prevent delamination. Factors like melt temperature, viscosity, and chemical affinity are critical considerations.

Applications

Co-molding is revolutionizing product design across diverse sectors, enabling highly functional and aesthetically appealing components:

-

Multi-colored Parts: Keyboards, remote controls, automotive interior buttons, appliance control panels, and toys, where different colors are integrated without painting or secondary assembly.

-

Parts with Varying Stiffness/Tactile Zones: Power tool handles with rigid cores and soft-touch grips, medical device housings with both structural and ergonomic zones, automotive interior components combining hard and soft textures (e.g., dashboards, door panels).

-

Complex Geometries with Integrated Functions:

-

Integrated Seals and Gaskets: Eliminating separate sealing components in electronics, automotive sensors, or household appliances.

-

Living Hinges: Creating flexible hinge mechanisms within rigid parts.

-

Encapsulation: Protecting delicate internal electronics or sensors with a robust outer shell.

-

Optical Components: Combining clear lenses with opaque housings.

-

-

Automotive Industry: Interior trim, steering wheel components, control knobs, weatherstripping, and mirror housings that integrate multiple materials for aesthetics, feel, and function.

-

Medical Devices: Surgical tool handles, diagnostic equipment housings, wearable medical sensors requiring integrated soft components for patient comfort or sealing.

-

Consumer Electronics: Mobile phone casings, wearable devices, headphones, and gaming controllers with integrated soft-touch areas or multi-color designs.

Advantages

-

Greater Design Freedom and Complexity: Allows designers to create parts with highly intricate geometries and varying material properties within a single component, enabling innovative product features.

-

Functional Integration: Combines multiple functions into a single part (e.g., structure, grip, seal, color), reducing part count and simplifying bills of material.

-

Elimination of Secondary Operations: Significantly reduces or eliminates the need for post-molding assembly steps like gluing, welding, painting, or attaching separate gaskets, leading to substantial labor and cost savings.

-

Improved Part Quality and Performance: Achieves strong, consistent bonds between materials, leading to more durable parts with enhanced performance characteristics (e.g., better sealing, improved ergonomics).

-

Reduced Overall Cycle Time (vs. separate molding and assembly): While the machine cycle itself can be longer than single-shot, the elimination of assembly steps makes the overall production process much faster and more efficient.

-

Cost-Effective for High-Volume Production: The initial investment is high, but the long-term savings from reduced assembly and improved efficiency make it very economical for mass production.

Disadvantages

-

High Tooling Costs: Molds for co-molding are exceptionally complex, requiring precise machining, often multiple gates, and sophisticated rotating or sliding mechanisms. This leads to significantly higher initial tooling costs compared to single-shot molds.

-

Complex Process Control: Achieving optimal bonding and material flow requires precise control over multiple injection units, temperatures, pressures, and mold movements. This demands highly skilled operators and advanced machinery.

-

Material Compatibility Constraints: Selecting materials that bond well chemically and have compatible processing temperatures and shrinkage rates is crucial and can be challenging. Poor compatibility leads to delamination, warpage, or stress.

-

Longer Development Cycles: Due to the complexity of tooling and process setup, the initial development and prototyping phase can be more extensive.

-

Larger Machine Footprint: Multi-shot machines are generally larger and more expensive than standard injection molding machines.

-

Limited Material Combinations: While versatile, not all material combinations are possible or practical due to compatibility issues.

Comparison Table

To help clarify the distinctions and aid in decision-making, the table below provides a side-by-side comparison of insert molding, overmolding, and co-molding across various critical parameters.

| Feature / Process | Insert Molding | Overmolding | Co-molding (Multi-shot Molding) |

| Definition | Molding plastic around a pre-formed non-plastic or pre-existing component (insert). | Molding a second material (often softer/different) over an existing plastic part (substrate). | Molding two or more different materials into a single part within one molding cycle. |

| Substrate/Insert Type | Pre-formed non-plastic (metal, ceramic, electronics, etc.) or a previously molded plastic part treated as an insert. | Pre-molded plastic part (rigid substrate) that the second material molds onto. | Two or more different materials molded sequentially/simultaneously in the same machine. |

| Process Flow | 1. Insert placement. 2. Plastic injection around insert. 3. Ejection. | 1. Substrate molded. 2. Substrate transferred to second cavity/mold. 3. Second material injected onto substrate. 4. Ejection. | 1. First material injected. 2. Mold reconfigures (rotates/slides). 3. Second material injected. 4. (Repeat for more shots). 5. Ejection. |

| Typical Materials | Inserts: Metal, ceramic, glass, electronics. Molded: Thermoplastics (ABS, Nylon, PC, PP). | Substrate: Rigid Thermoplastics (ABS, PC, Nylon, PP). Overmold: TPEs, TPUs, softer plastics. | Various compatible Thermoplastic-Thermoplastic or Thermoplastic-TPE combinations. |

| Key Application Focus | Part reinforcement, electrical conductivity, enhanced thread strength, integrating electronics. | Soft-touch grips, ergonomic enhancements, integrated seals, vibration damping, aesthetic differentiation. | Multi-color parts, integrated seals, varying stiffness zones, complex functional integration without assembly. |

| Advantages | Improved strength, reduced assembly, cost-effective for high volume, compact design. | Enhanced aesthetics/ergonomics, improved grip, integrated sealing, vibration damping, reduced assembly. | Greater design freedom, functional integration, elimination of secondary operations, high quality. |

| Disadvantages | Potential insert damage, limited insert design flexibility, complex insert placement, specific tooling. | Material compatibility challenges, potential delamination, more complex tooling, shrinkage differences. | Very high tooling costs, complex process control, strict material compatibility, longer development cycles. |

| Tooling Complexity | Moderate to High (needs to hold inserts) | High (requires two cavities or mold changes) | Very High (multi-station molds, rotating platens, multiple injection units) |

| Typical Machine | Standard injection molding machine (often with automation for insert placement). | Standard IMM (with automation for transfer) or specialized 2K/Multi-shot IMM. | Specialized 2K/Multi-shot injection molding machine. |

| Cost (Initial) | Moderate to High | High | Very High |

| Cost (Per Part, High Vol.) | Low to Moderate (due to assembly savings) | Moderate (due to assembly savings) | Low (most cost-effective due to no assembly) |

| Primary Bond Type | Mechanical Interlock, Adhesion | Chemical/Mechanical Adhesion | Chemical/Mechanical Adhesion |

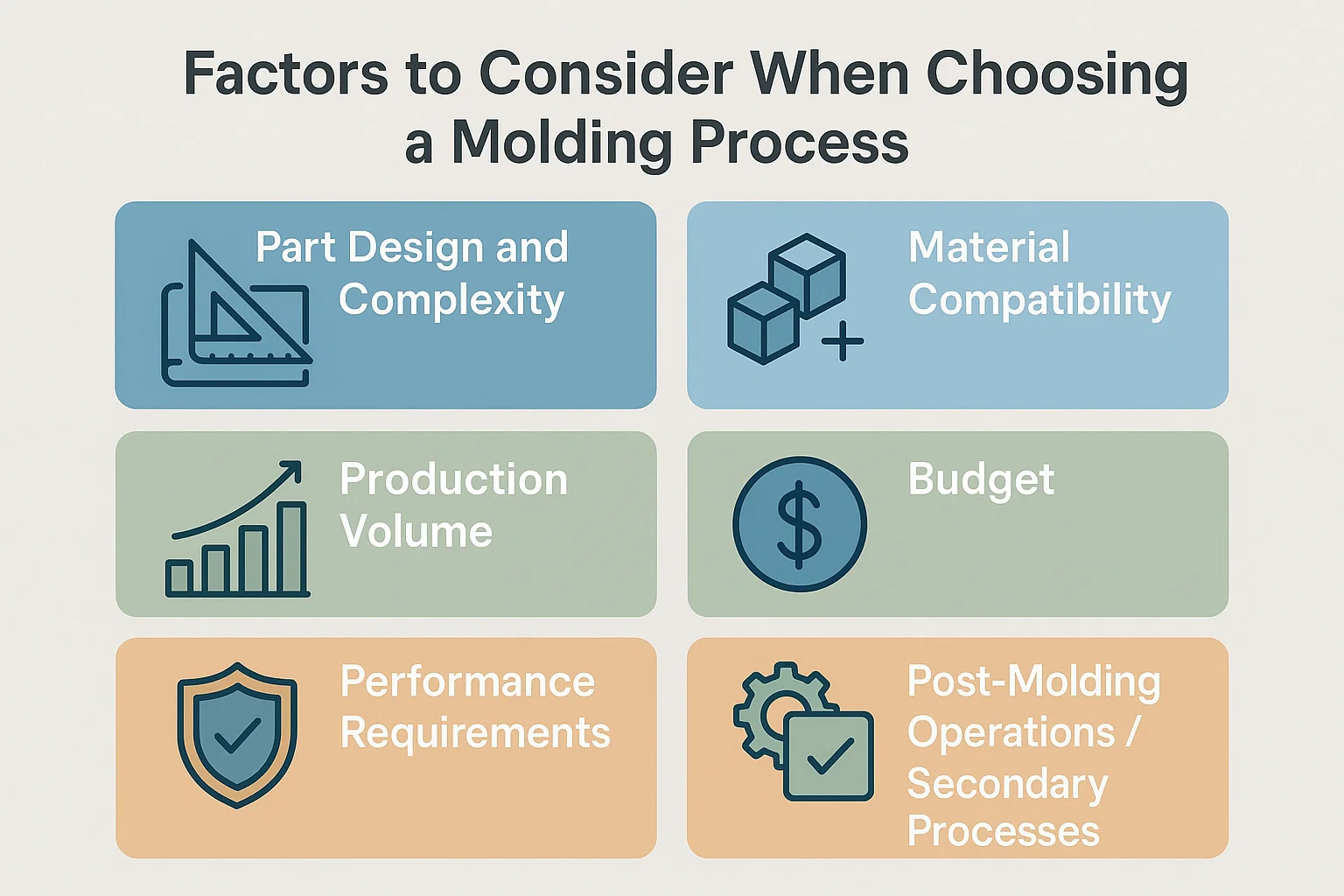

Factors to Consider When Choosing a Molding Process

Selecting the most appropriate molding process among insert molding, overmolding, and co-molding is a critical decision that impacts product performance, manufacturing efficiency, and overall cost. A thorough evaluation of several key factors is essential before committing to a specific technique.

1. Part Design and Complexity

-

Geometry and Integration:

-

Insert Molding: Ideal when you need to integrate discrete, pre-formed components (often non-plastic like metal or electronics) into a plastic part. Consider if the insert's shape can be securely held in the mold and withstand injection pressures.

-

Overmolding: Best suited for adding a softer, more ergonomic, or aesthetically distinct layer onto apre-existing plastic substrate. Evaluate if the overmold material can flow cleanly over the substrate's contours without trapping air or creating voids.

-

Co-molding: Offers the highest design freedom for integrating multiple plastic-based materials directly in one process. It's excellent for complex multi-color features, integrated seals, or parts with varying stiffness zones.

-

-

Dimensional Tolerances: All methods require careful consideration of material shrinkage, especially when combining different materials. Co-molding, in particular, demands precise control due to the multiple materials solidifying simultaneously.

-

Functional Requirements: What specific properties does each part of the component need? Is it strength, grip, sealing, electrical conductivity, or aesthetics? This will heavily influence material selection and thus the process.

2. Material Compatibility

-

Adhesion: This is paramount, especially for overmolding and co-molding. The chosen materials must form a strong chemical or mechanical bond to prevent delamination or separation over time. Research specific material grades and their compatibility (e.g., specific TPE grades for bonding with PC or Nylon).

-

Processing Temperatures: The melt temperatures of the different materials should be compatible. In overmolding and co-molding, the second material's melt temperature must not be so high that it damages or deforms the first material (substrate).

-

Shrinkage Rates: Differing shrinkage rates between combined materials can lead to warpage, internal stresses, or poor dimensional stability in the final part. Engineers often use simulation software to predict and mitigate these issues.

3. Production Volume

-

Low to Medium Volume:

-

Insert Molding (manual placement): Can be viable for lower volumes where the cost of automated insert placement isn't justified.

-

Overmolding (manual transfer): Similarly, if parts are manually transferred between molds, it can suit lower production runs, though labor costs become a factor.

-

-

High Volume:

-

Automated Insert Molding: Essential for high-volume insert molding to maintain efficiency and precision.

-

Two-Shot (Multi-shot) Overmolding & Co-molding: These processes are specifically designed for high-volume, high-efficiency production. The significant upfront tooling and machine investment is amortized over millions of parts, making them extremely cost-effective per piece.

-

4. Budget

-

Initial Tooling Costs:

-

Insert Molding: Typically moderate to high, as the mold needs features to secure the inserts.

-

Overmolding: High, especially for multi-cavity or rotating molds.

-

Co-molding: The highest, due to the extreme complexity of multi-shot molds and specialized machinery.

-

-

Machine Investment: Multi-shot injection molding machines required for co-molding and integrated overmolding are significantly more expensive than standard machines.

-

Per-Part Cost: While initial costs are high for advanced methods, the elimination of secondary operations (assembly, painting, sealing) can drastically reduce the per-part cost in high-volume production, leading to overall savings.

5. Performance Requirements

-

Durability and Lifespan: Does the part need to withstand harsh environments, repeated use, or specific loads? This influences material choice and the integrity of the bond between materials.

-

Environmental Factors: Will the part be exposed to chemicals, UV light, extreme temperatures, or moisture? Material selection and bonding mechanisms must account for these conditions.

-

Aesthetics: Is a specific look, feel, or color combination critical to the product's market appeal? Overmolding and co-molding excel at delivering integrated aesthetic features.

-

Certifications/Standards: For industries like medical or automotive, specific material properties and manufacturing processes must meet stringent regulatory standards.

6. Post-Molding Operations / Secondary Processes

-

One of the primary drivers for choosing these advanced molding techniques is the reduction or elimination of post-molding assembly.

-

Insert Molding: Reduces assembly of fasteners, bushings, etc.

-

Overmolding & Co-molding: Can eliminate manual gluing of grips, assembly of seals, or painting for multi-color parts.

-

-

Evaluate the true "total cost of ownership" by factoring in not just molding costs, but also labor, equipment, and quality control associated with secondary operations. The higher initial investment in advanced molding can often pay for itself by drastically cutting these subsequent costs.

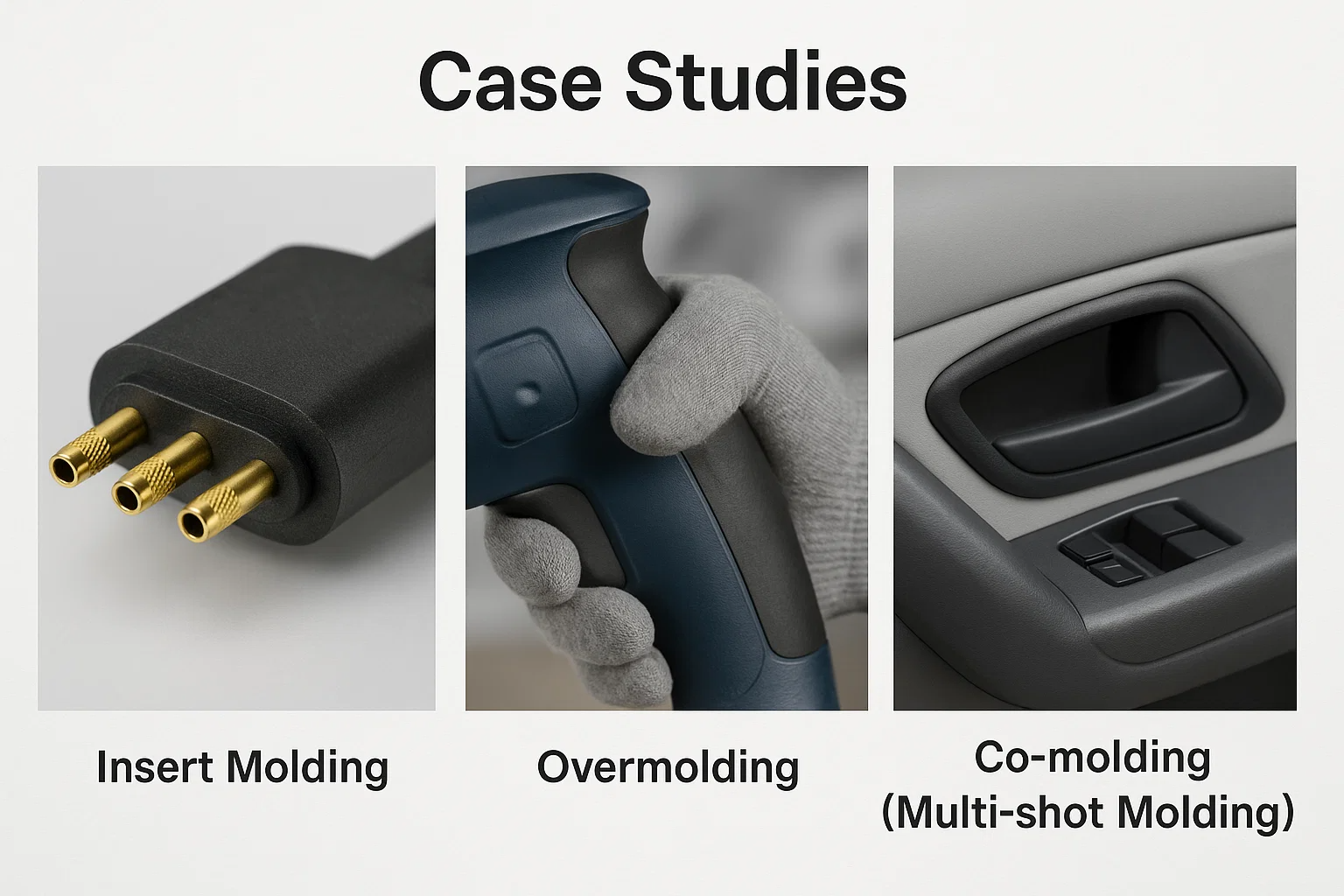

Case Studies

To illustrate the practical application and benefits of each molding process, let's explore real-world examples where insert molding, overmolding, and co-molding have been successfully employed to create innovative and efficient products.

Insert Molding: Electronic Connectors

Challenge: A manufacturer of consumer electronics needed to produce highly reliable USB-C connectors. The connector required robust metal pins for electrical conductivity and structural integrity, integrated seamlessly into a plastic housing that would provide insulation and a secure interface with devices. Traditional assembly of individual pins into a plastic housing was slow, prone to misalignment, and costly due to manual labor.

Solution: The company opted for insert molding. Precision-machined brass pins were pre-formed and then automatically placed into a multi-cavity mold. Molten Liquid Crystal Polymer (LCP), chosen for its excellent electrical insulation properties, dimensional stability, and high-temperature resistance, was then injected around the pins.

Result: This process allowed for the creation of hundreds of thousands of highly consistent, durable, and precisely aligned USB-C connectors per day. The strong mechanical lock between the LCP and the knurled features on the brass pins ensured exceptional pull-out strength and long-term reliability. The elimination of manual pin insertion significantly reduced manufacturing costs and assembly time, while improving the overall quality and miniaturization of the connector.

Overmolding: Power Tool Handles

Challenge: A leading power tool company aimed to improve the ergonomics, grip, and user comfort of its cordless drills. The existing handles, made solely of rigid ABS plastic, became slippery when hands were sweaty or oily, leading to user fatigue and potential safety issues. Adding a separate rubber grip was an extra assembly step and sometimes resulted in adhesive failure over time.

Solution: The manufacturer implemented overmolding using a two-shot injection molding process. First, the structural handle body was molded from a durable, rigid ABS plastic. This rigid "substrate" was then rotated within the same molding machine to a second cavity. Here, a soft, elastomeric Thermoplastic Vulcanizate (TPV) was injected over specific areas of the ABS handle, forming a comfortable, non-slip grip.

Result: The overmolded handles provided superior grip, significantly enhanced user comfort, and improved safety, especially in demanding work environments. The chemical and mechanical bond between the ABS and TPV ensured excellent adhesion, preventing delamination even after prolonged heavy use. This integrated solution eliminated the need for separate grip assembly, streamlining the manufacturing process and reducing overall production costs while delivering a premium user experience.

Co-molding (Multi-shot Molding): Automotive Interior Components

Challenge: An automotive supplier sought to produce a sophisticated car door panel component that integrated multiple functions and aesthetics, including a hard structural base, a soft-touch armrest, and distinct colored buttons for window controls. Traditionally, this involved molding several separate parts and then assembling them, leading to complex supply chains, potential fitment issues, and higher labor costs.

Solution: The supplier adopted a co-molding (multi-shot molding) process using a specialized three-shot injection molding machine.

-

Shot 1: A rigid, glass-filled Polypropylene (PP) was injected to form the structural backbone of the door panel and the base for the buttons.

-

Shot 2: A soft-touch Thermoplastic Polyurethane (TPU) was injected onto designated areas to create the comfortable armrest surface and other ergonomic zones.

-

Shot 3: A contrasting colored, UV-stabilized ABS was injected to form the distinct window control buttons directly onto the rigid PP base.

Result: This advanced co-molding approach enabled the production of a highly integrated, multi-material door panel component in a single, continuous process. It achieved superior aesthetic quality with seamless transitions between materials and colors, while ensuring durable mechanical and chemical bonds. The significant reduction in part count and elimination of multiple assembly steps led to substantial cost savings, reduced logistical complexity, and improved overall part quality and consistency for the automotive interior.

Insert molding excels at incorporating pre-formed, often non-plastic, components into a plastic part, primarily to enhance structural integrity, electrical conductivity, or provide specific functional features. It's the go-to for durable, integrated components like electronic connectors or reinforced gears.

Overmolding, particularly when applying softer materials onto a rigid plastic substrate, shines in improving product ergonomics, aesthetics, and user interaction. From soft-touch grips on power tools to integrated seals on electronic devices, it elevates comfort, safety, and functionality.

Co-molding (multi-shot molding) represents the pinnacle of multi-material integration within a single molding cycle. It offers unparalleled design freedom for creating complex parts with multiple colors, varying stiffnesses, and intricate integrated functions, often eliminating entire assembly lines in high-volume production.

Ultimately, the choice among these powerful injection molding processes hinges on a careful evaluation of your project's specific needs:

-

What materials are you combining, and what are their properties?

-

What level of design complexity and functional integration is required?

-

What is your projected production volume?

-

What are your budget constraints, both upfront and per-part?

-

What are the critical performance and aesthetic requirements of the final product?

Still confused which to choose, simply contact us at https://www.imtecmould.com/contact/.

English

English bahasa Indonesia

bahasa Indonesia