Mold Core vs. Mold Cavity: Understanding the Key Differences in Injection Molding

Introduction to Mold Cores and Mold Cavities

Injection molding is a cornerstone of modern manufacturing, used to produce a vast array of plastic products, from car dashboards to bottle caps. It's a precise process where molten plastic is injected into a mold to form a desired shape. The quality and accuracy of the final part depend almost entirely on the design and construction of the mold itself.

A typical injection mold is composed of two primary halves: the mold core and the mold cavity. Together, these two halves form the complete shape of the part. While they work in tandem, they each have distinct functions and characteristics.

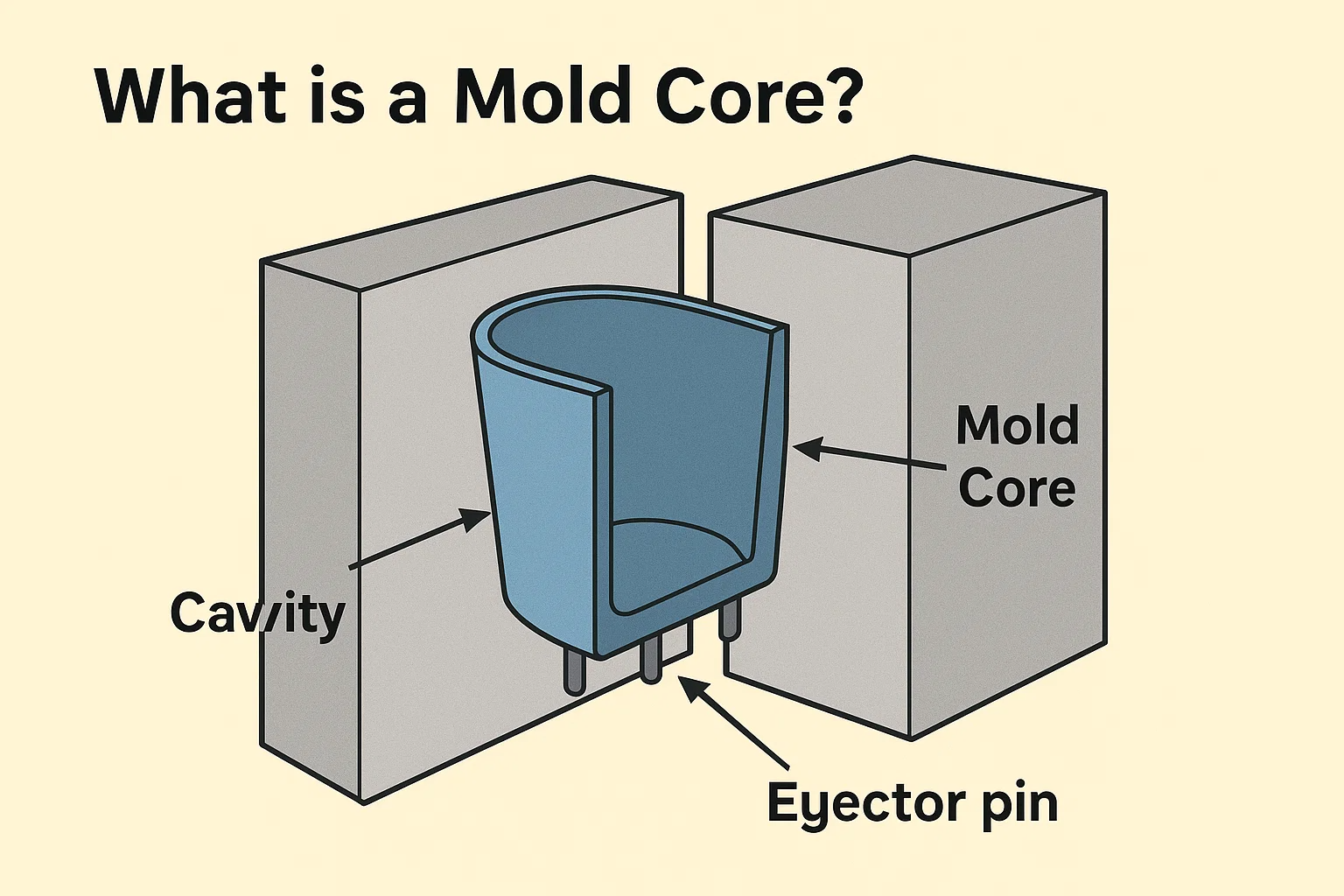

What is a Mold Core?

The mold core, also known as the "B-side" or "core half" of the mold, is the component that forms the internal features of a plastic part. When the mold is closed, the core fits inside the cavity, creating the space into which the molten plastic is injected. Think of it like a punch that creates the hollow or recessed areas within a part.

For example, if you're molding a plastic cup, the core would be the part that forms the inside of the cup. For a hollow box, the core would form the interior space. The core also typically contains features like ejector pins, which are used to push the finished part out of the mold after it has cooled. Because it forms the internal shape, the core often has a more complex design with features such as ribs, bosses (cylindrical protrusions for mounting), and other intricate details.

Commonly, mold cores are made from durable and heat-resistant materials like hardened steel, tool steel, or, for lower production volumes, aluminum. The choice of material depends on factors such as the plastic being molded, the part's complexity, and the required production volume.

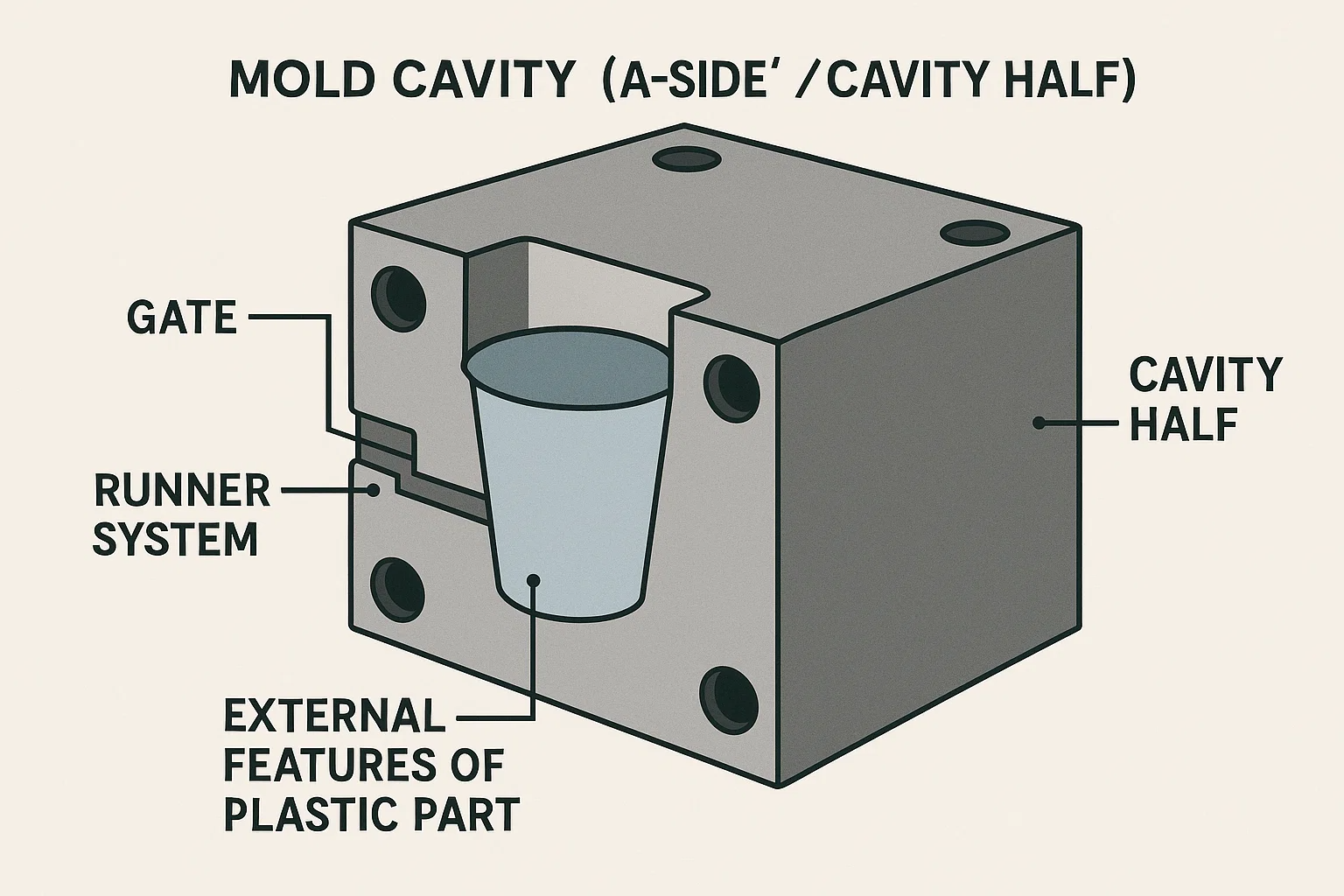

What is a Mold Cavity?

The mold cavity, also known as the "A-side" or "cavity half," is the component that forms the external features of the plastic part. It is the outer shell or container that the molten plastic fills. Using the plastic cup analogy, the cavity would form the outside of the cup, including its lip and outer walls.

The cavity half of the mold is typically where the gate and runner system are located. This system is the channel through which the molten plastic (or resin) flows from the injection unit into the mold. The cavity also requires careful design considerations for venting, which allows trapped air to escape as the plastic fills the mold. Proper venting is crucial for preventing defects like short shots (incomplete parts) and burn marks.

Like the core, mold cavities are made from steel or aluminum, with the material chosen based on the same factors of durability and cost. While the core forms the internal shape, the cavity is what gives the part its final external form and surface finish.

Key Differences Between Mold Cores and Mold Cavities

The core and cavity are two sides of the same coin, but they have fundamentally different roles in injection molding. Understanding these distinctions is crucial for proper mold and part design.

Shape Formation: Internal vs. External

The most significant difference lies in the shape each component forms. The mold core creates the internal shape and features of the part, such as holes, hollow sections, or the inside of a container. In contrast, the mold cavity forms the external shape, including the outer surface, decorative details, and the overall dimensions of the part. This division of labor is what allows for the creation of complex, three-dimensional objects.

Position Relative to the Parting Line

The parting line is the line where the two halves of the mold meet. The cavity half is typically on the sprue side (the side where the plastic is injected), and it forms the visible outer surface of the part. The core half is on the ejector side, and it's where the finished part is pushed out of the mold. The location of the ejector pins on the core side is a key difference, as they are not found on the cavity side.

Role in the Injection Molding Process

-

Core: The core is often the side with the ejection system, which includes ejector pins and return pins. Its main role is to facilitate the removal of the cooled part from the mold.

-

Cavity: The cavity is the side that typically contains the gate and runner system, which directs the molten plastic into the mold. Its primary role is to receive the injected material and form the outer shell.

| Feature | Mold Core | Mold Cavity |

| Primary Function | Forms the internal shape of the part | Forms the external shape of the part |

| Position in Mold | Ejector side (B-side) | Sprue side (A-side) |

| Key Features | Ejector pins, slides, lifters | Gates, runners, vents |

| Role in Process | Ejects the finished part | Receives injected plastic |

| Impact on Part | Affects internal features, strength, and ejection | Affects surface finish, texture, and cosmetic appearance |

Impact on Part Design and Functionality

The core and cavity have a direct impact on the final part's design. Features on the core side, like ribs and bosses, are crucial for adding strength or for assembly purposes. The design of the core can also dictate the need for specific draft angles to ensure the part can be cleanly ejected. The cavity side, on the other hand, determines the surface finish, texture, and cosmetic appearance of the part. Any imperfections in the cavity will be visible on the final product.

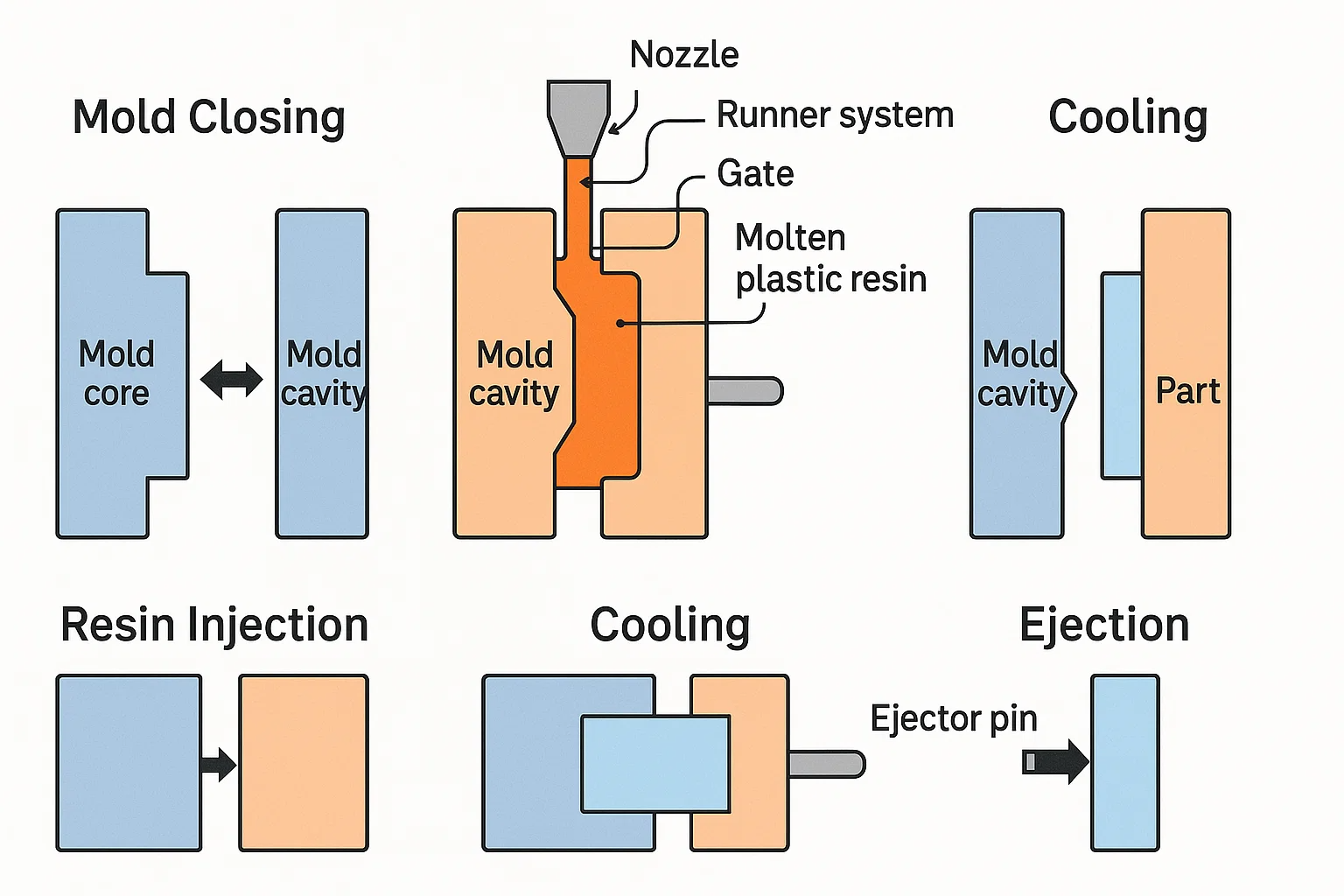

The Injection Molding Process: Core and Cavity in Action

The core and cavity don't just sit statically; they are dynamic partners in a highly synchronized manufacturing process. Here's a step-by-step breakdown of how they work together:

-

Mold Closing: The process begins with the mold core and mold cavity moving toward each other until they clamp together. This action creates the sealed internal void—the shape of the final part. The accuracy of this alignment is critical, as any misalignment can cause a "flash" (excess material seeping out along the parting line).

-

Resin Injection: Molten plastic resin is injected under high pressure through a nozzle and into the mold. The material travels through the runner system and gate—which are part of the cavity half—and fills the space between the core and cavity. The core displaces the resin to form the part's internal shape, while the cavity forms the outer shell.

-

Cooling: After the resin fills the mold, a dedicated cooling system circulates a fluid (usually water or oil) through channels within both the core and cavity. This process solidifies the plastic from the outside in, with the core and cavity halves acting as heat sinks to cool the part efficiently.

-

Ejection: Once the part has cooled and solidified, the mold opens. The ejection system—located on the core half—activates, using ejector pins to push the newly formed part off the core. Because the part often shrinks onto the core during cooling, the core's design must incorporate draft angles to prevent it from getting stuck and to ensure a clean release. The part then falls into a collection bin or is picked up by a robotic arm.

Design Considerations for Mold Cores and Cavities

The design of the core and cavity is a meticulous process that dictates the success of the final part. Engineers must consider several critical factors to ensure functionality, manufacturability, and a high-quality finish.

Draft Angles and Their Importance

A draft angle is a slight taper or slant applied to the vertical walls of a plastic part. It is essential for a clean release from the mold. Without proper draft, the part can stick to the core or cavity, leading to damage, warping, or difficult ejection. The draft must be designed on both the core and cavity sides to ensure that the part doesn't catch on either half as the mold opens.

Cooling Channel Design

Proper cooling is vital for reducing cycle time and preventing defects like warpage and sink marks. Engineers design intricate cooling channels within both the core and cavity halves. These channels circulate a cooling fluid to evenly and quickly extract heat from the molten plastic, ensuring uniform solidification. The design of these channels must be optimized for the part's geometry to avoid hot spots.

Gating and Runner System Design

The runner system is the network of channels that guides the molten plastic from the injection nozzle to the mold cavity. The gate is the point where the runner meets the part. The gate and runner are almost always located on the cavity half. Their design is crucial for controlling how the resin fills the mold, as it affects the part's flow marks, knit lines, and overall strength.

Ejection System Design

The ejection system is located exclusively on the core half of the mold. It consists of ejector pins, blades, or sleeves that push the finished part off the core. The number, size, and location of these pins must be carefully considered to apply even force, preventing the part from deforming or being damaged during ejection.

Venting Considerations

As the plastic resin fills the mold, air trapped inside must have a way to escape. Venting, typically designed into the parting line or the cavity half, consists of small, shallow channels that allow air to be pushed out. Insufficient venting can lead to cosmetic defects like burn marks and functional problems like short shots, where the part is incomplete.

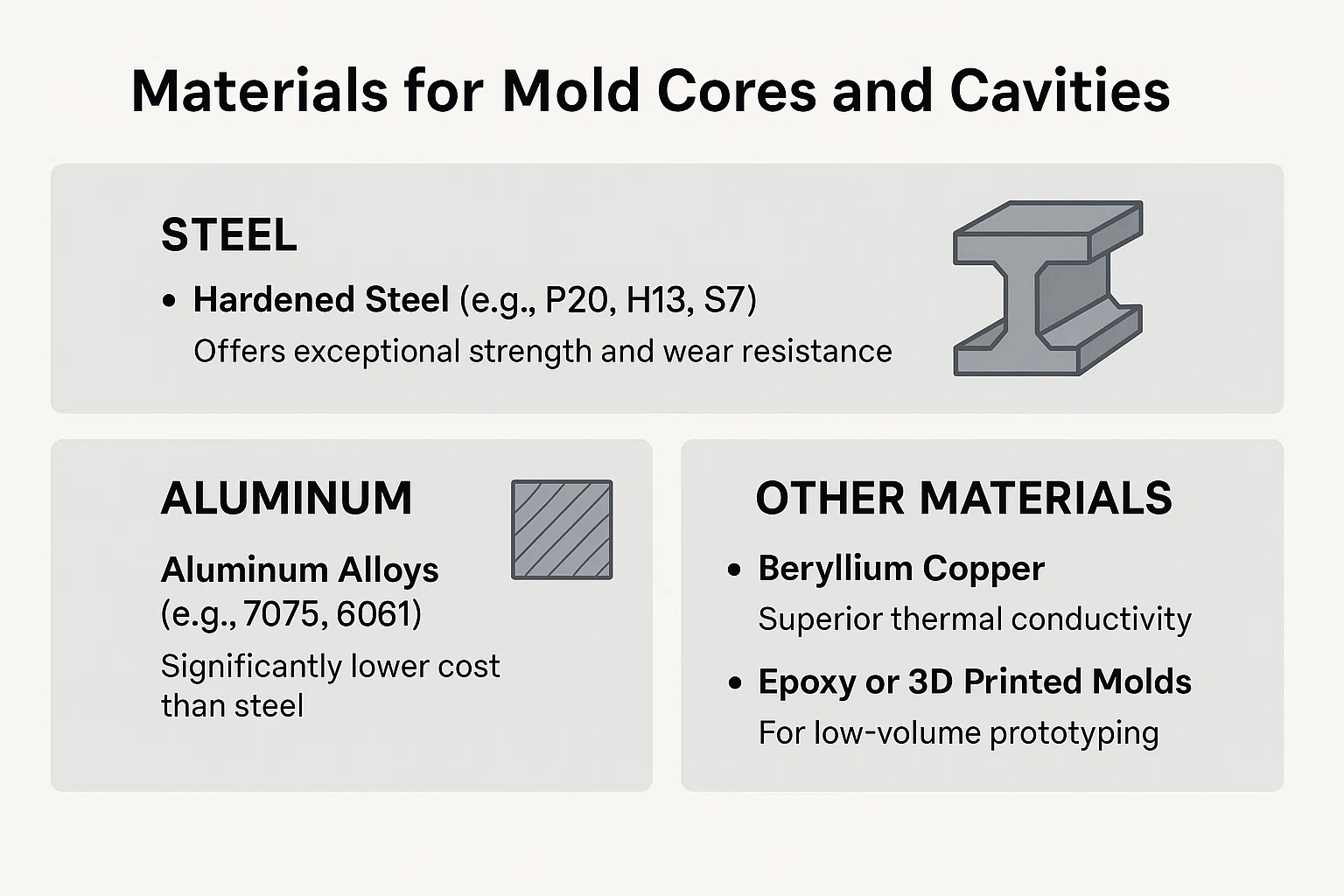

Materials for Mold Cores and Cavities

The material chosen for the mold core and cavity is critical, as it directly affects the mold's durability, cost, and ability to produce high-quality parts efficiently. The selection depends on factors like the type of plastic being molded, the required production volume, and the complexity of the part design.

Steel

Steel is the most common and preferred material for injection molds, particularly for high-volume production runs.

-

Hardened Steel (e.g., P20, H13, S7): This type of steel offers exceptional strength and wear resistance. It's ideal for producing millions of parts over the mold's lifetime. P20 is a popular choice for its balance of hardness and machinability. H13 and S7 are excellent for applications requiring resistance to heat and pressure. The high hardness of these steels allows for a superior surface finish.

-

Stainless Steel (e.g., 420 SS): This is used when the plastic material being molded is corrosive or when the mold will be used in a humid environment. It provides excellent corrosion resistance, which is crucial for maintaining a pristine mold surface.

Aluminum

Aluminum alloys (e.g., 7075, 6061) are often used for prototype molds or for low-volume production runs (typically under 100,000 parts).

-

Advantages: Aluminum offers several benefits, including a significantly lower cost than steel and a much faster machining time. Its excellent thermal conductivity allows for faster cooling, which can reduce the injection molding cycle time.

-

Disadvantages: It is less durable and more susceptible to wear and damage than steel. It may not be suitable for molding abrasive or glass-filled plastics.

Other Materials

-

Beryllium Copper: This material is an excellent choice for mold inserts or components where rapid heat removal is critical, such as in areas with a thick wall section. It has superior thermal conductivity compared to steel, making it ideal for localized cooling.

-

Epoxy or 3D Printed Molds: For very low-volume or rapid prototyping, non-traditional materials can be used. These are inexpensive and quick to produce but have very limited lifespans and are not suitable for complex or high-precision parts.

Manufacturing Mold Cores and Cavities

The manufacturing of mold cores and cavities is a highly precise and specialized process. It requires advanced machinery and skilled craftsmanship to transform raw material blocks into the intricate, functional components of an injection mold. The goal is to achieve extremely tight tolerances and a flawless surface finish.

Machining Processes: CNC Milling and EDM

-

CNC Milling (Computer Numerical Control): This is the primary method for shaping both the core and cavity. CNC machines use computer-guided cutting tools to remove material layer by layer. They are essential for creating the basic geometry, pockets, and most of the detailed features. Modern multi-axis CNC machines can produce complex, curved surfaces with incredible accuracy.

-

EDM (Electrical Discharge Machining): Also known as spark machining, EDM is a non-contact process used for creating features that are difficult or impossible to machine with traditional cutting tools. It works by using electrical sparks to erode material. EDM is particularly useful for creating sharp corners, deep ribs, and very small, intricate features in hardened steel.

Surface Treatment and Finishing

After machining, the mold surfaces are polished and treated to achieve the desired texture and durability.

-

Polishing: Mold surfaces are polished to a mirror finish to ensure the part releases easily and to produce a smooth, high-gloss surface on the final product. The core, in particular, often requires a highly polished finish to aid in ejection.

-

Texturing: Texturing, or adding a grain or pattern to the mold surface, is often done to give the final part a specific aesthetic look or feel. This can also help to hide cosmetic defects like flow marks.

-

Coatings: Coatings like electroless nickel plating or TiN (titanium nitride) are applied to increase the mold's hardness, corrosion resistance, and lubricity, extending its lifespan and reducing wear.

Quality Control and Inspection

Throughout the manufacturing process, strict quality control measures are in place. High-precision instruments like Coordinate Measuring Machines (CMMs) are used to verify that the dimensions and tolerances of the core and cavity are accurate to within a few micrometers. This meticulous inspection is vital for ensuring the mold will produce consistent, high-quality parts without defects.

Common Problems and Solutions

Even with meticulous design and manufacturing, injection molding can encounter common issues. Many of these problems are directly related to the interaction between the mold core and mold cavity.

Warpage and Distortion

Problem: Warpage is the deformation of a plastic part after it cools. It's typically caused by uneven cooling rates. If the core and cavity cool the part at different rates, internal stresses can build up, causing the part to bend or twist.

Solution: The most effective solution is to optimize the design of the cooling channels in both the core and cavity. Ensuring that cooling is uniform across the entire mold surface is essential. Adjusting the melt temperature, injection pressure, and holding time can also help to mitigate internal stress.

Short Shots and Sink Marks

Problem: A short shot occurs when the plastic resin fails to completely fill the mold cavity, resulting in an incomplete part. This is often due to insufficient pressure or poor venting. Conversely, sink marks are depressions on the surface of a part, caused by the plastic shrinking as it cools, pulling the surface inward.

Solution: For short shots, the solution involves improving the venting on the mold cavity to allow trapped air to escape. Increasing the injection pressure, speed, or melt temperature can also help. For sink marks, the issue is typically a result of a thick wall section or insufficient cooling. Solutions include redesigning the part to have uniform wall thickness, increasing the holding pressure, or improving the efficiency of the cooling channels in both the core and cavity.

Ejection Problems

Problem: Ejection issues occur when the finished part sticks to the mold and cannot be cleanly removed. This is almost always a problem with the core half of the mold. It can be caused by insufficient or improperly designed draft angles, an inadequate ejection system, or the part shrinking onto the core too tightly.

Solution: The primary solution is to ensure all walls on the core side have a proper draft angle. Increasing the number of ejector pins or optimizing their placement to distribute the ejection force more evenly can also solve the problem. If the material is prone to sticking, a highly polished surface finish or a specific mold release agent can be used.

| Problem | Likely Cause | Solution |

| Warpage | Uneven cooling, internal stress | Optimize cooling channels, adjust processing parameters. |

| Short Shots | Trapped air, low pressure | Improve venting on the cavity, increase injection pressure. |

| Sink Marks | Thick walls, insufficient cooling | Redesign part for uniform thickness, increase holding pressure on the cavity. |

| Ejection Problems | Insufficient draft angle, part stuck | Add or increase draft angles on the core, add more ejector pins. |

So

The distinction between the mold core and the mold cavity is fundamental to the entire injection molding process. While they are two halves of a single tool, they perform distinctly different, yet complementary, functions. The mold cavity forms the external shape of the part, defining its outer dimensions and cosmetic surface. In contrast, the mold core creates the internal shape and features, and also plays the critical role of facilitating part ejection.

Together, the core and cavity represent the heart of injection molding, turning raw plastic resin into a precise, finished product. A deep understanding of their individual functions and design requirements is crucial for preventing common defects, optimizing production efficiency, and ultimately, producing high-quality plastic parts that meet exacting standards.

English

English bahasa Indonesia

bahasa Indonesia