Introduction

Nylon Injection Molding: A Comprehensive Guide

Injection molding stands as the single most important and widely utilized process for mass-producing plastic parts. This manufacturing technique involves injecting molten material into a mold cavity, where it cools and solidifies into the final desired shape. The process is responsible for creating everything from common household goods and sophisticated medical equipment to critical automotive components.

While the technique itself is versatile, its success hinges on the properties of the material used. Enter Nylon, also known chemically as Polyamide (PA).

Nylon is a high-performance thermoplastic, meaning it can be repeatedly melted and reformed without significant chemical degradation. Since its invention, it has become one of the most popular and important engineering plastics in the world.

Why Nylon is a Popular Choice for Injection Molding

Nylon’s popularity in injection molding is rooted in its unique balance of properties that are often unavailable in other, lower-cost plastics:

-

Exceptional Mechanical Properties: Nylon offers a combination of high strength, stiffness, and toughness, making it ideal for parts subjected to high loads and stresses.

-

Superior Wear Resistance: It possesses an inherently low coefficient of friction, making it the material of choice for parts that involve movement or sliding against other surfaces, such as gears and bearings.

-

Thermal Stability: It can withstand higher operating temperatures than many other common thermoplastics, crucial for applications in engine bays or electrical components.

-

Chemical Resistance: It offers good resistance to many oils, fuels, and solvents.

The capability to rapidly transform raw polyamide pellets into complex, durable, and precisely engineered parts makes nylon injection molding an indispensable process across numerous high-demand industries.

What is Nylon Injection Molding?

Definition and Core Process

Nylon injection molding is a high-volume manufacturing process used to create complex, three-dimensional parts by injecting molten polyamide (nylon) into a mold cavity. As a thermoplastic, nylon is heated until it becomes liquid, forced under high pressure into a closed mold, allowed to cool and solidify, and finally ejected as a finished part.

The process is fundamentally similar to the injection molding of other plastics, but it requires specific attention to temperature, moisture control, and injection pressure due to nylon's unique material characteristics (specifically its high melting point and hygroscopic nature).

Key Steps in Nylon Injection Molding

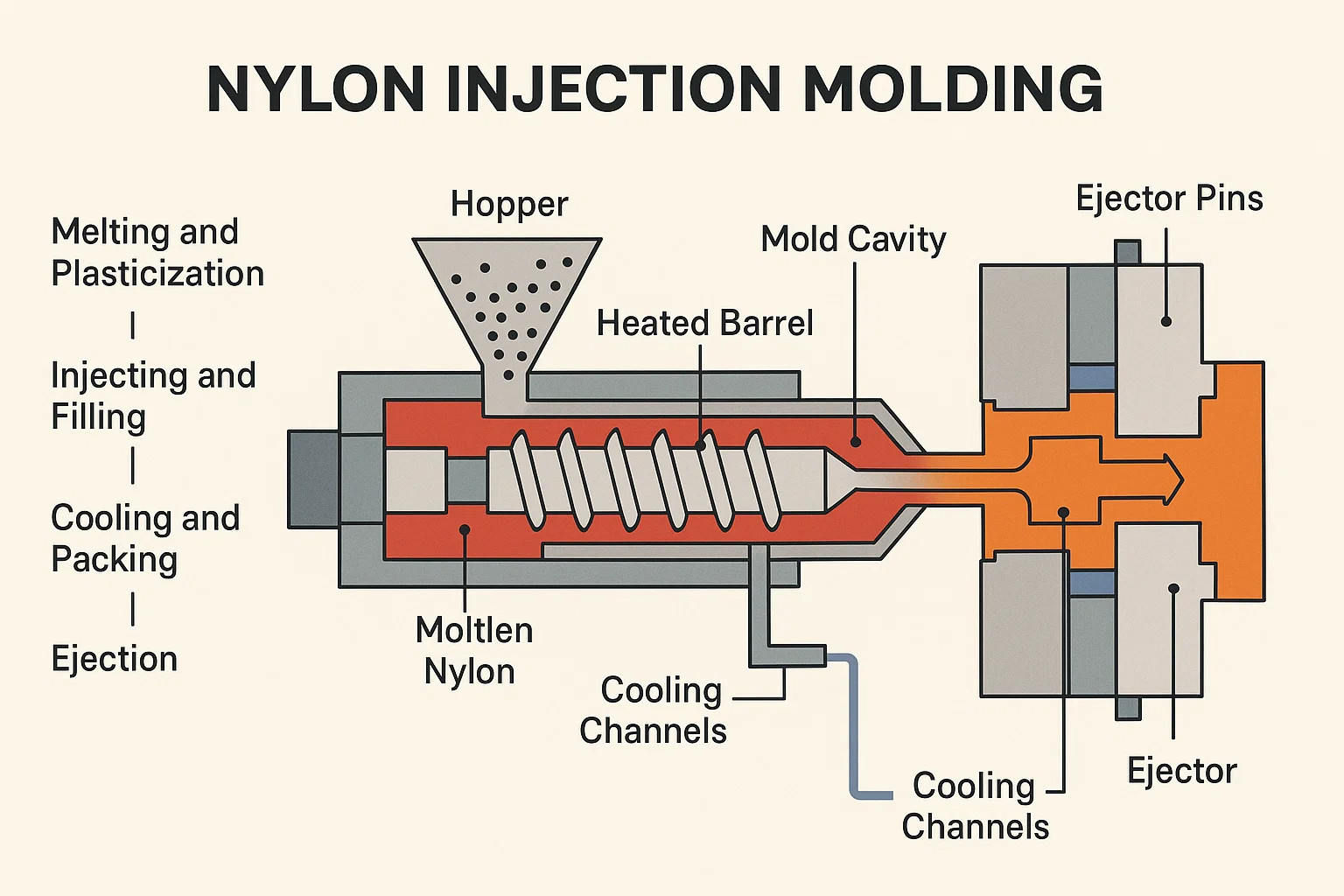

The entire process is cyclical and involves four core stages:

1. Melting and Plasticization

The raw nylon material (typically in pellet form) is fed from a hopper into a heated barrel. A reciprocating screw inside the barrel shears and compresses the material. The combination of heat from the barrel heaters and frictional heat from the screw movement melts the nylon and moves it toward the front of the barrel. This step must be carefully controlled to prevent thermal degradation of the nylon, which can compromise the final part's mechanical properties.

2. Injecting and Filling

Once a sufficient "shot" of molten nylon has accumulated, the screw rapidly moves forward, acting as a plunger. This action forces the molten nylon at very high pressure through the nozzle, the sprue, the runners, and the gates, finally filling the mold cavity. Injection speed and pressure are crucial and must be optimized to ensure the thin-walled, crystalline nylon fills all sections without causing defects like short shots or jetting.

3. Cooling and Packing

After the mold cavity is filled, a brief packing (or holding) pressure is maintained to compensate for the material's shrinkage as it begins to cool and solidify. Nylon is a semi-crystalline plastic, meaning it shrinks significantly. This packing pressure is vital for minimizing defects like sink marks and ensuring dimensional accuracy. Cooling water circulating through channels in the mold removes heat, causing the part to solidify.

4. Ejection

Once the part is sufficiently rigid, the mold opens, and the ejector pins push the finished nylon part out of the cavity. Because nylon parts can be relatively tough even when warm, appropriate draft angles and pin locations are critical to ensure smooth ejection without damaging the part or the mold. The mold then closes, ready to begin the next cycle.

Types of Nylon Materials & Composites

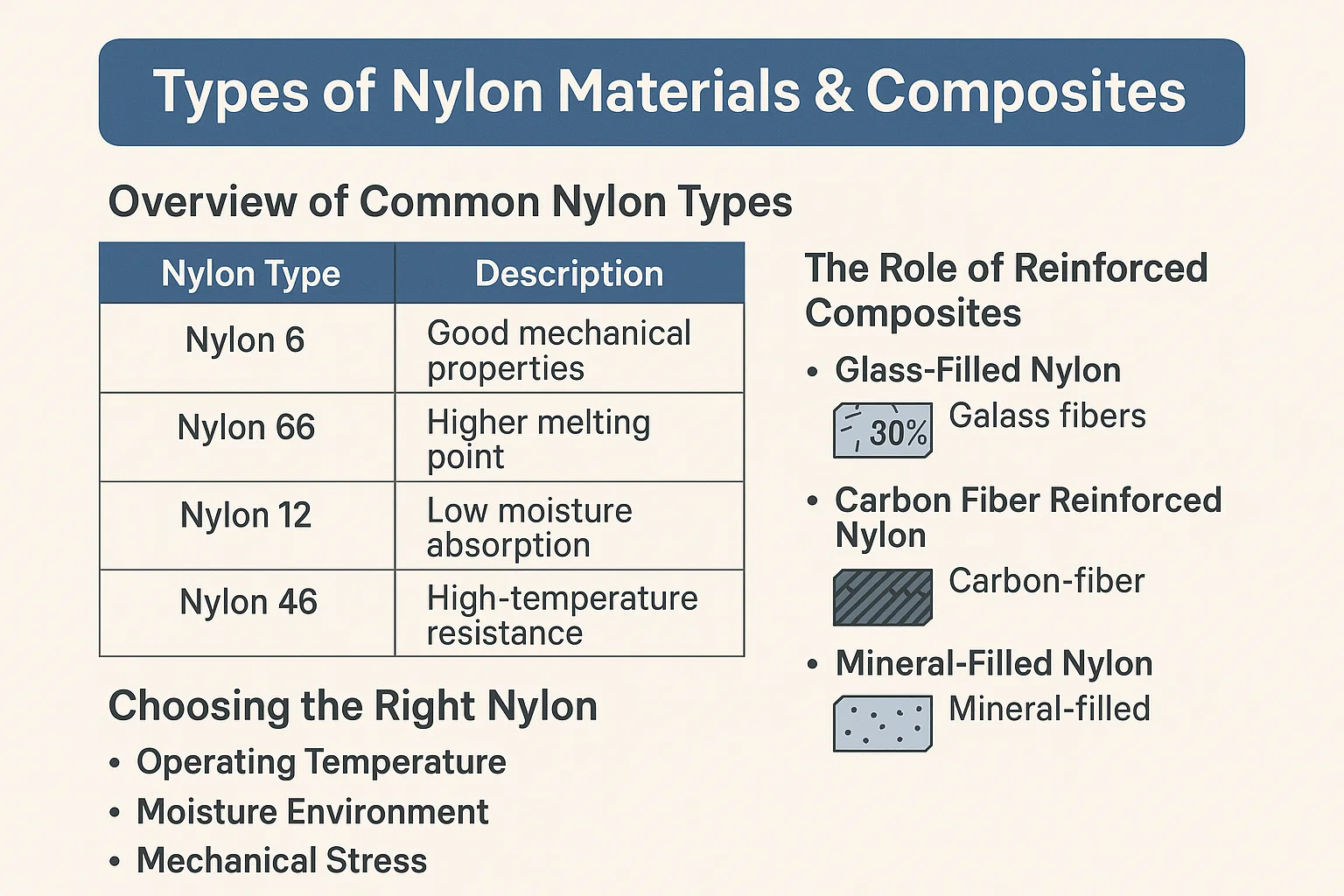

While often referred to simply as "nylon," polyamide encompasses a family of materials, each with a unique chemical structure that dictates its properties and suitability for different injection molding applications. The two numbers that follow "Nylon" (e.g., Nylon 6, Nylon 66) refer to the number of carbon atoms in the starting monomers.

Overview of Common Nylon Types

| Nylon Type | Primary Characteristics | Key Applications |

| Nylon 6 (PA6) | Good balance of mechanical strength, stiffness, and impact resistance; easier to process than PA66. Higher moisture absorption than PA66. | Automotive trims, appliance parts, gears, bearings, power tool housings. |

| Nylon 66 (PA66) | Higher melting temperature, superior heat and chemical resistance, and better wear properties than PA6; higher processing costs. | Engine covers, radiator end tanks, electrical connectors, high-temperature structural components. |

| Nylon 12 (PA12) | Lowest density and lowest moisture absorption among common nylons; excellent chemical resistance and dimensional stability. | Fuel lines, air brake tubing, precise components requiring excellent dimensional stability. |

The Role of Reinforced Composites

For applications requiring even greater strength, stiffness, or thermal performance, nylon is frequently compounded with reinforcing fillers.

-

Glass-Filled Nylon: The most common composite involves adding glass fibers (e.g., Nylon 6 GF30, meaning Nylon 6 with 30% glass fiber). This drastically increases the material's tensile strength, stiffness (modulus), and heat deflection temperature. However, it also increases material shrinkage, which can lead to higher warpage and requires careful mold design.

-

Carbon Fiber Reinforced Nylon: Used when maximum stiffness, strength, and reduced weight are critical. Carbon fiber provides superior mechanical properties but comes at a higher material cost.

-

Mineral-Filled Nylon: Used to improve dimensional stability, reduce shrinkage, and achieve smoother surface finishes, though usually with a trade-off in impact strength.

Choosing the Right Nylon

Selecting the appropriate nylon involves a careful trade-off between competing material properties and cost:

-

Operating Temperature: If the part is near a heat source, the higher melting point of Nylon 66 or a glass-filled composite is often required.

-

Moisture Environment: For parts that will operate in high humidity or underwater, Nylon 12 offers the best dimensional stability due to its low water absorption.

-

Mechanical Stress: Parts under constant load or high impact generally require a highly crystalline grade or a glass-filled version of Nylon 6 or 66.

Advantages of Using Nylon in Injection Molding

Nylon's success as an engineering plastic is due to its impressive combination of mechanical, thermal, and chemical properties, offering distinct benefits over commodity plastics and even some metals.

1. High Strength and Stiffness

Nylon grades (especially PA66 and glass-filled composites) exhibit excellent tensile strength and modulus of elasticity (stiffness). This makes them ideal for structural components that must bear significant loads without deforming, such as brackets, levers, and machine housings.

2. Excellent Wear and Abrasion Resistance

Nylon possesses an inherently low coefficient of friction and high abrasion resistance. This property is paramount for dynamic applications where parts slide or rub against one another.

-

Key Application: Nylon is frequently used for self-lubricating parts like gears, bearings, and bushings, reducing the need for external lubricants.

3. Good Chemical Resistance

Polyamides offer strong resistance to a wide range of organic chemicals, including:

-

Oils and Greases: Crucial for automotive and industrial machinery components.

-

Fuels: Making it suitable for fuel system parts.

-

Solvents: Providing durability in harsh cleaning or operating environments.

4. High Heat Resistance

Compared to many common thermoplastics like polyethylene (PE) or polypropylene (PP), nylon can withstand significantly higher operating temperatures. This is especially true for Nylon 66, and even more so when reinforced with glass fiber, which drastically increases the Heat Deflection Temperature (HDT). This thermal stability allows its use in demanding applications like under-the-hood automotive parts.

5. Fatigue and Impact Resistance

Nylon has excellent resistance to fatigue, meaning it can endure repeated stress cycles (loading and unloading) without cracking. Furthermore, many nylon grades, particularly non-filled types, maintain good impact resistance even at lower temperatures, ensuring durability against sudden shocks.

6. Good Electrical Insulation Properties

Nylon is an effective electrical insulator. Its high dielectric strength and resistance to tracking make it a common choice for:

-

Electrical Connectors: Ensuring current flows correctly and safely.

-

Housings and Insulators: Protecting sensitive electronics.

Disadvantages of Using Nylon in Injection Molding

Despite its numerous advantages as a high-performance engineering plastic, nylon presents specific material and processing challenges that must be managed for successful injection molding.

1. High Moisture Absorption (Hygroscopic Nature)

The most significant challenge with nylon is its hygroscopic nature—it readily absorbs moisture from the surrounding environment.

-

Impact on Material: Before molding, excessive moisture leads to hydrolysis during the high-temperature melting process. This reaction breaks down the polymer chains, resulting in a severe loss of molecular weight and thus, a dramatic reduction in the final part's mechanical strength and impact resistance (often manifesting as brittleness).

-

Solution: Nylon must be thoroughly dried to a very low moisture content (typically less than 0.1% for PA66) immediately before processing.

2. Dimensional Instability Due to Moisture

Post-molding, nylon parts will absorb moisture until they reach equilibrium with the ambient environment. This moisture absorption causes the material to swell, leading to significant dimensional changes.

-

Design Consideration: Designers must account for the difference in dimensions between the dry, as-molded part and the stabilized, conditioned part, especially for components requiring high precision.

3. Potential for Hydrolysis and Degradation

As mentioned, if moisture is present during melting, the material degrades. Even if properly dried, nylon has a relatively narrow processing window compared to some other thermoplastics. Overheating or excessive residence time in the barrel can cause thermal degradation, leading to:

-

Discoloration (often yellowing).

-

Reduced mechanical properties.

-

The release of corrosive ammonia gas.

4. High Material Shrinkage

Nylon is a semi-crystalline polymer, meaning its internal structure changes significantly upon cooling. This leads to a relatively high and anisotropic (uneven) volumetric shrinkage (often 1% to 2%).

-

Consequence: High shrinkage increases the risk of warpage and makes maintaining tight dimensional tolerances more challenging than with amorphous plastics.

5. Higher Cost

Compared to commodity thermoplastics like Polypropylene (PP) or Polyethylene (PE), nylon grades are generally more expensive. The cost is justified by the superior performance, but it is a factor that limits its use to engineering applications where its strength and heat resistance are strictly required.

Design Considerations for Nylon Injection Molding

Effective part design is non-negotiable when working with crystalline materials like nylon. Designers must prioritize uniformity and smooth transitions to manage high material shrinkage, minimize internal stresses, and ensure efficient processing.

1. Wall Thickness Guidelines

-

Uniformity is Key: The single most important rule is to maintain a uniform wall thickness throughout the part. Because nylon shrinks significantly upon cooling, variations in thickness will lead to varying cooling rates, which is the primary driver of internal stress and warpage.

-

Optimal Thickness: While specific guidelines vary by grade, typical wall thicknesses range from 0.040 to 0.150 inches (1.0 to 3.8 mm). Thicker walls should be avoided or cored out to maintain uniformity.

2. Rib Design for Added Strength

Ribs are essential for adding strength and stiffness without dramatically increasing wall thickness.

-

Rib Thickness: The thickness of a rib should be between 50% and 60% of the nominal wall thickness it supports. Making the rib too thick risks creating a sink mark on the opposing surface.

-

Rib Height: Rib height should generally be no more than three times the nominal wall thickness.

3. Draft Angles for Easy Ejection

Because nylon parts are stiff and are ejected while still warm, sufficient draft (taper) is necessary to ensure they release smoothly from the mold without scuffing or warping.

-

Minimum Draft: Aim for a minimum draft of 0.5° to 1.0° per side. For deep draws or textured surfaces, increase the draft angle to 2° or more.

4. Gate Location and Design

The gate is the entry point for the molten plastic, and its placement significantly affects part quality, especially for a high-shrink material like nylon.

-

Minimize Knit Lines: Locate gates to push the melt front together in non-critical areas, as the weld or knit line created when two melt fronts meet will have reduced strength.

-

Gate Size: The gate should be sized large enough to allow sufficient packing pressure to be transmitted into the cavity, which is essential for minimizing sink marks and controlling shrinkage.

-

Control Warpage: Gate near areas with heavy features or large, flat sections to ensure the necessary packing pressure is applied where shrinkage is most likely to cause warpage.

5. Avoiding Stress Concentrations

-

Corner Radii: Avoid sharp internal corners. Sharp 90° corners create stress concentration points where the part is highly likely to crack or fail under load.

-

Recommended Radius: All internal corners should have a radius of at least 50% of the adjacent wall thickness (R ≥ 0.5T).

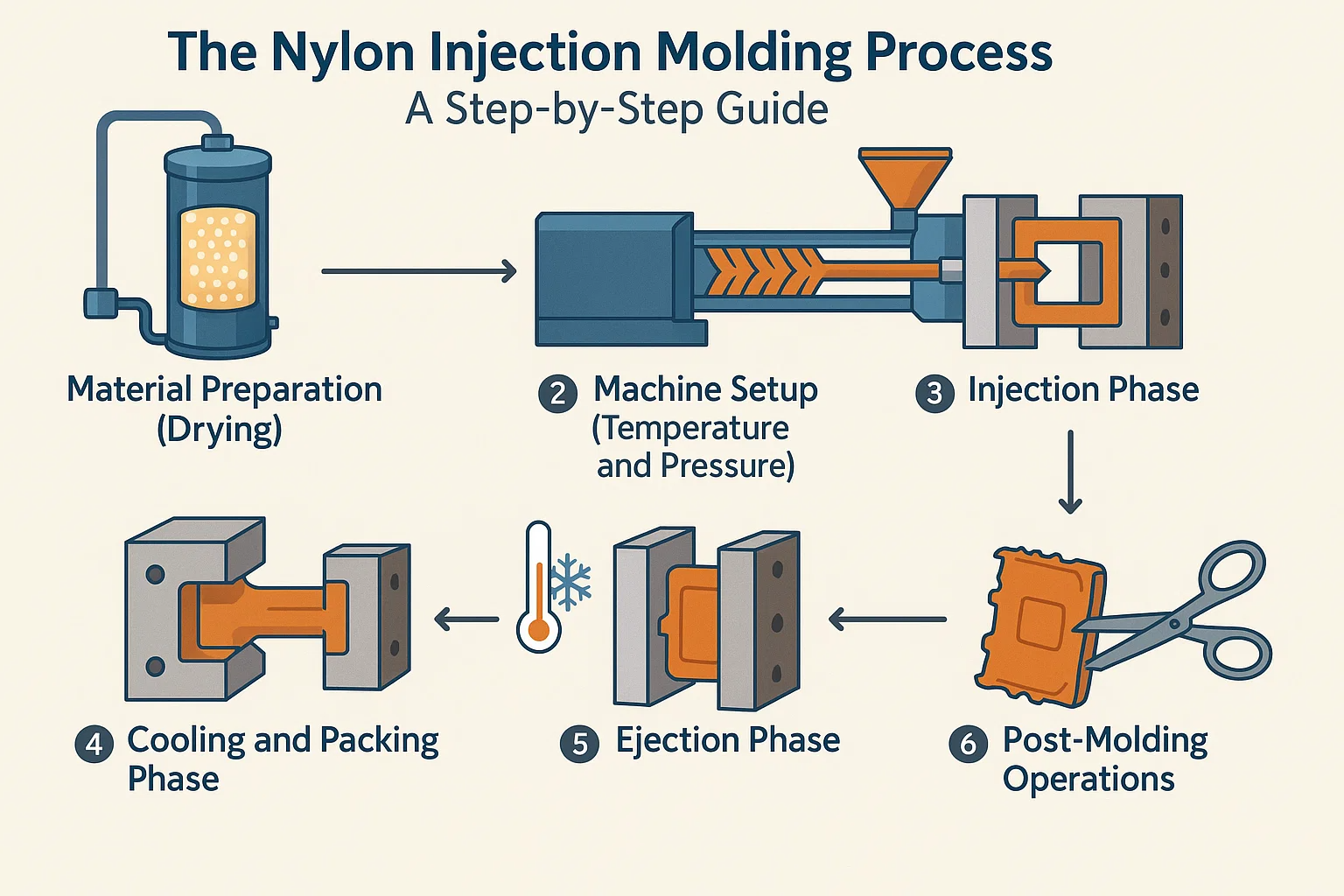

The Nylon Injection Molding Process: A Step-by-Step Guide

The successful molding of nylon requires meticulous attention to process parameters, primarily driven by its sensitivity to moisture and its semi-crystalline nature.

1. Material Preparation (Drying)

This is arguably the most critical step. Due to nylon's hygroscopic nature, moisture absorbed from the air must be removed before melting. If not dried, the moisture causes the material to degrade through hydrolysis during processing, resulting in weak, brittle parts.

-

Requirement: Nylon must be dried in a desiccant dryer or vacuum oven to a residual moisture level of less than 0.1% (often lower for PA66).

-

Procedure: Drying typically takes 4–6 hours at temperatures between 80°C and 110°C (176°F and 230°F), depending on the specific nylon grade and filler content.

2. Machine Setup (Temperature and Pressure)

Nylon requires high processing temperatures due to its high melting point.

-

Melt Temperature: The barrel temperature profile is set to achieve a melt temperature that ensures the nylon is fully molten but prevents thermal degradation. Typical melt temperatures range from 230°C to 300°C (446°F to 572°F).

-

Mold Temperature: A high mold temperature is essential for nylon (often between 80°C and 120°C / 176°F and 248°F). A hotter mold helps maintain melt fluidity, facilitates full crystallization, reduces internal stresses, and minimizes warpage.

-

Back Pressure: Low to moderate back pressure is generally used to ensure good melt homogenization without creating excessive shear heat, which could cause degradation.

3. Injection Phase

The molten nylon is injected into the mold cavity.

-

Injection Speed: A fast injection speed is often preferred to quickly fill the mold cavity while the nylon melt is still hot and fluid. This is crucial for preventing short shots and minimizing the formation of prominent knit lines (weld lines).

-

Injection Pressure: High injection pressures are typically necessary to overcome the viscosity of nylon and ensure dense packing.

4. Cooling and Packing Phase

As the nylon cools, it shrinks significantly.

-

Packing (Holding) Pressure: Pressure is maintained immediately after injection (the packing phase) to force more material into the cavity to compensate for volumetric shrinkage. This pressure is crucial for preventing sink marks in thick sections and ensuring dimensional accuracy.

-

Cooling Time: Cooling must be sufficient to allow the crystalline structure to fully develop and ensure the part is rigid enough for ejection without deformation.

5. Ejection Phase

Once cooled, the mold opens, and the ejector system removes the part.

-

Handling: Parts are ejected while the mold is still hot. Proper draft angles and well-designed ejection pins are vital to avoid structural damage or cosmetic blemishes (stress whitening).

6. Post-Molding Operations

-

Trimming/Deflashing: Removing the gate remnants, runners, and any flash.

-

Conditioning (Optional but Common): Since the part is dry and dimensionally stableas-moldedbut brittle, it is often conditioned by soaking it in warm water or exposing it to a controlled humidity environment. This allows the part to absorb moisture, restoring its intended toughness, flexibility, and impact resistance.

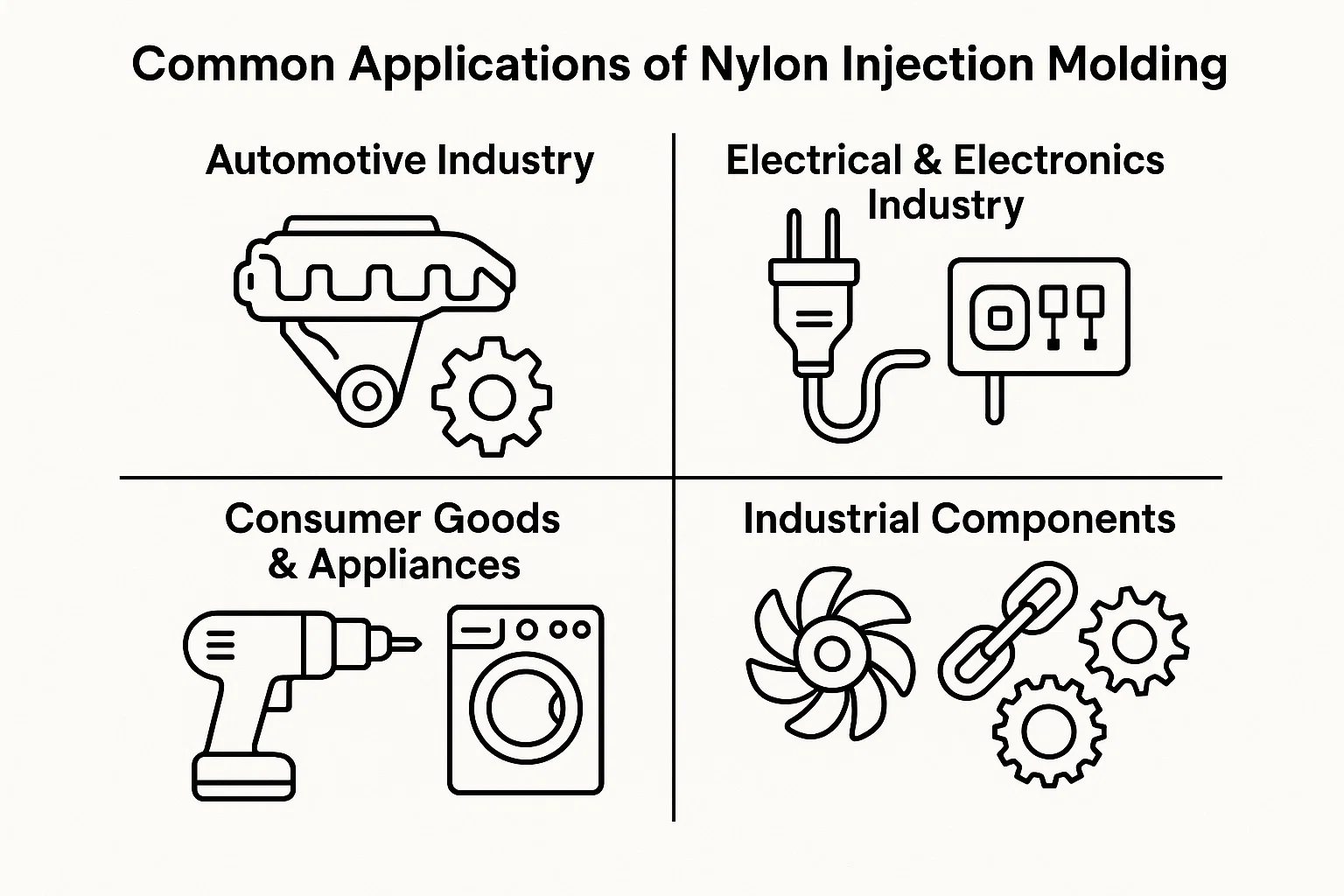

Common Applications of Nylon Injection Molding

Nylon’s unique combination of high strength, heat resistance, and excellent wear properties makes it a preferred choice for replacing metal in many demanding applications across various industries.

1. Automotive Industry

The automotive sector is one of the largest consumers of injection-molded nylon, especially reinforced grades (glass-filled PA6 and PA66), where performance in high-heat environments is essential.

-

Under-the-Hood Components: Engine covers, intake manifolds, cooling system components (radiator end tanks), and oil filter housings.

-

Mechanical Parts: Gears, bearings, thrust washers, and bushings that require low friction and high durability.

-

Safety and Structure: Airbag containers and various structural brackets and clips.

2. Electrical and Electronics Industry

Due to its high dielectric strength and heat resistance, nylon is ideal for components that manage power or require fire-resistant properties.

-

Connectors and Housings: Electrical plugs, terminal blocks, power tool housings, and circuit breaker components.

-

Insulators: Spacers, standoffs, and various insulating barriers.

3. Consumer Goods and Appliances

Nylon is used where durability, sleek aesthetics, and resistance to wear are required in everyday items.

-

Power Tools: Housings and internal moving parts for drills, sanders, and saws.

-

Appliances: Gears, cams, and structural parts for washing machines, vacuum cleaners, and kitchen appliances.

-

Sports Equipment: Ski bindings, cycling components, and durable buckles.

4. Industrial Components

Nylon's excellent chemical and wear resistance makes it critical for fluid handling and heavy machinery.

-

Fluid Systems: Pump parts, valve bodies, impellers, and fluid couplings due to resistance to oils and chemicals.

-

Machinery: Rollers, chain guides, sprockets, and wear plates.

5. Medical Devices

Nylon 6 and Nylon 66, particularly specialized, bio-compatible grades, are used for components that require sterilization and precise mechanical function.

-

Surgical Instruments: Handles, clamps, and non-implantable components.

-

Diagnostic Equipment: Housings and mechanical parts.

Troubleshooting Common Nylon Injection Molding Problems

Even with optimal design and machine setup, issues can arise. Effective troubleshooting of nylon parts requires understanding how the material's high shrinkage, crystallinity, and moisture sensitivity manifest as defects.

1. Warping (Deformation)

Warpage is the distortion or twisting of the part after cooling, and it is the most common issue with semi-crystalline materials like nylon.

-

Causes:

-

Uneven Cooling: The primary cause; often due to non-uniform wall thickness or insufficient cooling in specific mold areas.

-

Anisotropic Shrinkage: High and directional shrinkage, especially with glass-filled materials.

-

Low Mold Temperature: A mold that is too cold prevents uniform crystallization.

-

-

Solutions:

-

Increase Mold Temperature: A hotter mold (closer to 100 °C ) ensures slower, more uniform cooling and crystal growth.

-

Optimize Gate Location: Place the gate to balance melt flow and control shrinkage direction.

-

Design Review: Ensure wall thickness is as uniform as possible.

2. Sink Marks (Depressions)

Sink marks are localized depressions on the surface of a part, typically occurring opposite thick sections, ribs, or bosses.

-

Causes:

-

Insufficient Packing Pressure: Not enough material is pushed in during the packing phase to compensate for internal shrinkage.

-

Wall Thickness Too High: The core of a thick section takes too long to cool and shrinks internally.

-

-

Solutions:

-

Increase Packing Pressure and Time: Maintain high holding pressure longer to feed material into the shrinking core.

-

Increase Gate Size: A larger gate allows the packing pressure to be effectively transferred.

-

Redesign: Reduce the thickness of the problematic section, or core it out.

-

3. Knit Lines (Weld Lines)

Knit lines (or weld lines) appear where two melt fronts converge, often around holes or inserts. For nylon, these lines are weak points.

-

Causes:

-

Low Melt Temperature/Slow Speed: The nylon cools too much before the melt fronts meet, preventing proper fusion.

-

-

Solutions:

-

Increase Melt Temperature: Ensure the nylon is hot enough for better molecular mixing upon meeting.

-

Increase Injection Speed: Fill the cavity faster to keep the melt front hot.

-

Redesign: Adjust gate location to move the knit line to a less structurally critical or hidden area.

-

4. Short Shots (Incomplete Fill)

A short shot is a failure to fully fill the mold cavity, leaving empty spaces.

-

Causes:

-

Low Melt Temperature: The nylon is too viscous to flow completely.

-

Insufficient Injection Pressure/Speed: Not enough force or speed to push the material to the end of the cavity.

-

-

Solutions:

-

Increase Melt Temperature and Injection Speed.

-

Vent the Mold: Ensure air can escape the cavity, especially in deep pockets.

-

5. Jetting (Worm-like Trail)

Jetting occurs when the molten nylon is shot rapidly into the cavity through a small gate, causing it to curl like a stream rather than fan out smoothly.

-

Causes:

-

Excessive Injection Speed through a small gate opening.

-

Poor Gate Design: Gate aims directly into a large, open area.

-

-

Solutions:

-

Reduce Injection Speed at the start of the fill (velocity profiling).

-

Increase Gate Size.

-

Redesign Gate Location: Aim the jet against a mold pin, core, or wall to force the stream to dissipate immediately.

-

6. Degradation (Brittleness/Yellowing)

Degradation is the chemical breakdown of the polymer, resulting in a loss of properties.

-

Causes:

-

Moisture (Hydrolysis): Most common cause; insufficient material drying.

-

Excessive Melt Temperature: Temperatures too high for the specific nylon grade.

-

Long Residence Time: The nylon sits in the hot barrel too long (e.g., small shots on a large machine).

-

-

Solutions:

-

Ensure Proper Drying: Re-check moisture content and dryer function.

-

Reduce Melt Temperature or Cycle Time.

-

Use the Right Machine: Select a molding machine where the shot size is 40%-80% of the barrel capacity.

-

-

-

Best Practices for Nylon Injection Molding

Successfully molding nylon consistently requires adherence to strict protocols that mitigate its fundamental challenges, primarily moisture and high shrinkage. Implementing these best practices ensures quality, durability, and optimal cycle times.

1. Proper Material Handling and Storage

-

Mandatory Drying: Always assume the nylon material requires drying. Use a desiccant dryer to reduce moisture content below the manufacturer's specified limit (typically <= 0.1\%) immediately prior to use.

-

Closed-Loop Feeding: Ideally, use a closed-loop system to feed the material directly from the dryer to the machine hopper to prevent re-absorption of ambient moisture during conveyance.

-

Storage: Store unsealed nylon bags or containers in a dry, climate-controlled environment or re-seal them immediately after opening.

2. Optimizing Process Parameters

-

High Mold Temperature: Utilize a high mold temperature (often 80 °C to 120 °C) to promote full and uniform crystallization. This reduces internal stresses, minimizes warpage, and improves the mechanical properties of the final part.

-

Fast Injection/Controlled Speed: Use a relatively fast injection speed to ensure the melt front stays hot and fuses well (reducing knit line weakness). However, use velocity profiling to start slower and avoid jetting at the gate.

-

Adequate Packing Pressure: Employ sufficient holding/packing pressure and time to compensate for nylon's high volumetric shrinkage and minimize sink marks.

3. Mold Maintenance and Gate Management

-

Gate Vestige Control: Ensure clean gate separation to minimize secondary trimming operations, which can damage the part.

-

Regular Cleaning: Regularly clean the mold vents and parting line. Proper venting is crucial for nylon's fast fill, allowing air to escape and preventing burning (dieseling) caused by compressed gas.

4. Quality Control and Post-Molding

-

Moisture Testing: Implement routine material moisture testing (e.g., Karl Fischer titration or moisture analyzer) to verify drying effectiveness.

-

Immediate Conditioning: Plan for post-molding conditioning (e.g., hot water bath or humidity chamber) for parts that require maximum toughness and impact resistance, as the dry, as-molded parts will be more brittle.

-

Dimensional Checks: Perform dimensional quality checks on partsafterthey have been conditioned and stabilized, as the dimensions will change significantly from the as-molded state.

So

Nylon injection molding is a powerful and essential manufacturing process that delivers high-performance, durable, and cost-effective components across the world's most demanding industries. Its unique profile of high strength, excellent wear resistance, and thermal stability makes polyamide indispensable for replacing traditional materials like metals in gears, housings, and connectors.

English

English bahasa Indonesia

bahasa Indonesia