Your Guide to China Injection Molding: Cost, Quality, and Finding the Right Partner

Introduction to China Injection Molding

Injection molding is a versatile and widely used manufacturing process for producing parts from thermoplastic and thermosetting plastic materials. It involves injecting molten material into a mold, where it cools and solidifies into the desired shape. This method is renowned for its ability to produce complex parts with high precision, excellent surface finish, and rapid production rates, making it indispensable across a multitude of industries, from automotive and medical to consumer electronics and household goods.

In recent decades, China has emerged as a dominant force in the global manufacturing landscape, and its injection molding industry is no exception. The country has become a preferred destination for businesses worldwide seeking injection molding services, largely due to its robust manufacturing infrastructure, competitive pricing, and extensive network of suppliers. This guide aims to provide a comprehensive overview of China injection molding, delving into critical aspects such as cost, quality, and the essential steps to finding the right manufacturing partner for your specific project needs.

However, choosing China for your injection molding needs comes with a unique set of advantages and disadvantages that warrant careful consideration:

Advantages of Choosing China for Injection Molding:

- Cost-Effectiveness: One of the primary drivers for outsourcing to China is the significantly lower labor costs compared to Western countries. This, combined with competitive material pricing and economies of scale, often results in a lower overall unit cost for manufactured parts.

- Established Infrastructure and Ecosystem: China boasts a highly developed manufacturing infrastructure and a vast ecosystem of supporting industries, including mold makers, material suppliers, and finishing services. This allows for streamlined production processes and quick access to resources.

- High Production Capacity: Chinese manufacturers often have large production capacities, making them well-suited for high-volume orders and mass production.

- Speed to Market: The efficiency and scale of Chinese manufacturing can often lead to faster prototyping and production cycles, accelerating time to market for new products.

- Technological Advancement: Many leading Chinese injection molding companies have invested heavily in state-of-the-art machinery and adopted advanced technologies, offering sophisticated capabilities and high-quality outputs.

- Experience and Expertise: With decades of experience in global manufacturing, Chinese suppliers have accumulated significant expertise in various injection molding techniques and material applications.

Disadvantages of Choosing China for Injection Molding:

- Communication Barriers: Language differences and cultural nuances can sometimes lead to misunderstandings or misinterpretations, making clear and consistent communication crucial.

- Intellectual Property (IP) Concerns: While efforts have been made to strengthen IP protection in China, some businesses still harbor concerns about safeguarding their designs and proprietary information. Thorough due diligence and robust legal agreements are essential.

- Quality Control Challenges (if not managed well): While high quality is achievable, maintaining consistent quality can be a challenge without proper oversight, stringent quality control measures, and clear specifications. It requires proactive engagement and a well-defined quality assurance plan.

- Logistics and Shipping Complexity: Managing international shipping, customs, and import duties can add layers of complexity and cost to the overall process.

- Lead Times for Tooling: While production can be fast, the initial tooling phase (mold creation) can still have significant lead times, especially for complex designs.

- Ethical and Environmental Considerations: It's important for businesses to ensure their chosen suppliers adhere to ethical labor practices and environmental regulations, aligning with their own corporate social responsibility goals.

Understanding the Injection Molding Process

To effectively engage with China injection molding services, it's crucial to have a foundational understanding of the injection molding process itself. This knowledge empowers you to communicate more effectively with manufacturers, understand technical specifications, and make informed decisions about your project.

Step-by-Step Explanation of the Injection Molding Process:

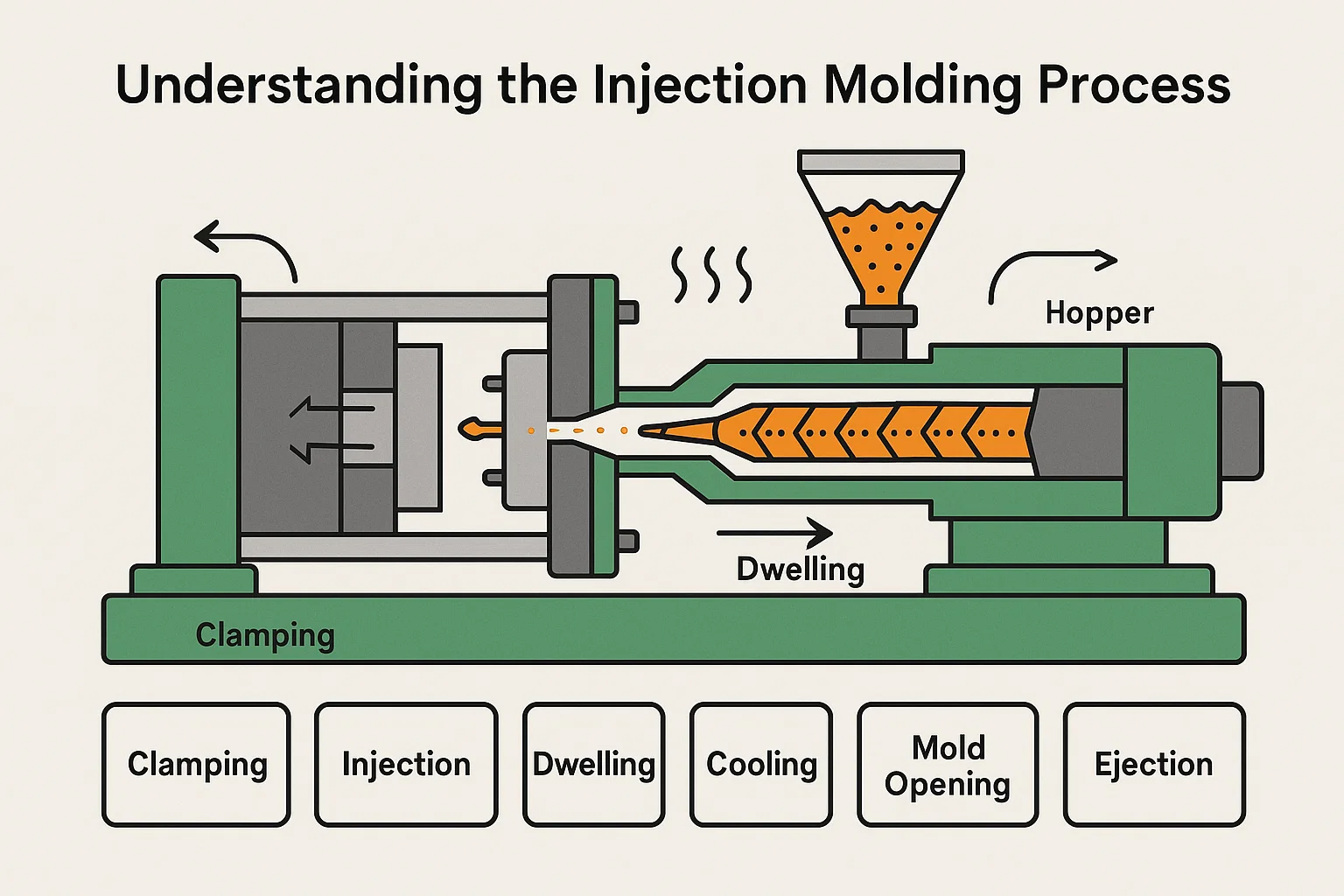

The injection molding process is a cyclical operation that, while appearing simple, involves precise control of temperature, pressure, and timing to create consistent parts. Here are the fundamental steps:

-

Clamping: The process begins with the clamping unit. Two halves of a mold (the cavity and the core) are securely clamped together by a powerful hydraulic or electric press. One half of the mold is typically stationary, while the other moves to open and close. This clamping force must be sufficient to withstand the immense pressure exerted during injection, preventing the mold from opening and flashing (molten plastic escaping between the mold halves).

-

Injection: Plastic pellets or granules are fed from a hopper into a heated barrel. Inside the barrel, a reciprocating screw rotates, melting the plastic material through a combination of heat and shear friction. Once the plastic is molten and a sufficient "shot" size (the amount of plastic needed for the part) is accumulated at the front of the screw, the screw moves forward like a plunger, injecting the molten plastic at high pressure and speed into the closed mold cavity through a system of runners and gates.

-

Dwelling (Packing/Holding): After the mold cavity is filled, a controlled amount of pressure, known as "dwelling" or "packing" pressure, is maintained. This sustained pressure helps to compensate for the volumetric shrinkage that occurs as the plastic cools and solidifies. It ensures that the mold cavities are completely filled, preventing sink marks, voids, and other defects, and promoting dimensional stability.

-

Cooling: With the plastic now fully packed into the mold, it begins to cool and solidify within the mold's shape. Cooling channels, often integrated into the mold design and circulating cool water or oil, facilitate this process. The cooling time is typically the longest part of the injection molding cycle and depends on factors such as the material used, wall thickness of the part, and mold design. Efficient cooling is critical for achieving desired part properties and minimizing cycle times.

-

Mold Opening: Once the part has sufficiently cooled and solidified, the clamping unit retracts, opening the two halves of the mold.

-

Ejection: As the mold opens, ejector pins, strategically placed within the mold, push the solidified part out of the mold cavity. These pins are designed to apply even pressure to avoid deforming or damaging the newly molded part. The part then falls onto a conveyor belt or into a collection bin.

-

Post-Processing (Optional): After ejection, some parts may require minor post-processing, such as trimming off runners or gates (the channels that guided the plastic into the mold cavity), deburring, or secondary operations like assembly, painting, or printing. In many cases, excess material from runners can be reground and reused, contributing to cost efficiency and reduced waste. The cycle then repeats.

Different Types of Injection Molding Techniques Used in China:

While the core process remains consistent, China's advanced manufacturing capabilities allow for a variety of specialized injection molding techniques to meet diverse product requirements:

- Standard Thermoplastic Injection Molding: This is the most common method, using thermoplastic polymers that can be repeatedly melted and solidified. It's suitable for a vast array of consumer and industrial products.

- Overmolding: This technique involves molding one material over another pre-existing component (the substrate), often to create a product with multiple materials, colors, or textures (e.g., soft-grip handles on tools, seals on electronic enclosures). The substrate can be plastic, metal, or another material.

- Insert Molding: Similar to overmolding, but here, pre-formed inserts (usually metal components like threaded inserts, pins, or electronic contacts) are placed into the mold before injection. The molten plastic flows around and encapsulates these inserts, creating a single integrated part. This enhances part strength, functionality, or enables electrical conductivity.

- Two-Shot (Multi-Shot) Injection Molding: This advanced process produces parts with two or more different plastic materials or colors in a single molding cycle, often in the same machine. It eliminates the need for assembly and allows for complex designs with distinct material properties or aesthetic features.

- Gas-Assisted Injection Molding: For parts with thick sections or those requiring improved surface finish and reduced sink marks, inert gas (like nitrogen) is injected into the mold cavity after a partial shot of molten plastic. The gas creates internal channels, pushing the plastic against the mold walls and reducing material usage and cooling time.

- Liquid Silicone Rubber (LSR) Injection Molding: This process is specifically designed for liquid silicone rubber, a thermoset material known for its flexibility, high-temperature resistance, and biocompatibility. It's often used for medical devices, seals, and consumer goods.

- Thin-Wall Molding: This technique focuses on producing parts with extremely thin wall sections, typically for applications where material reduction, lightweighting, and fast cycle times are critical, such as packaging or disposable consumer goods.

- Hot Runner Molds vs. Cold Runner Molds: These refer to the runner system (the channels that guide molten plastic to the mold cavities).

- Cold Runner Molds: The plastic in the runners cools and solidifies along with the part. This runner material is then ejected and must be removed from the part, often recycled. They are simpler and less expensive to build but can generate more waste.

- Hot Runner Molds: The runners are kept heated, so the plastic within them remains molten throughout the cycle. This means no material waste from the runners, leading to more efficient material usage, faster cycle times, and often a better cosmetic finish on the part. They are more complex and expensive to tool initially.

Materials Commonly Used in China Injection Molding:

Chinese injection molding facilities work with an extensive range of thermoplastic materials, chosen based on the desired mechanical, thermal, chemical, and aesthetic properties of the final product. Some of the most commonly used materials include:

- Polypropylene (PP): A versatile and cost-effective thermoplastic known for its excellent chemical resistance, fatigue resistance, and flexibility. It's widely used in packaging, automotive components, consumer goods, and living hinges.

- Acrylonitrile Butadiene Styrene (ABS): A tough, rigid, and impact-resistant engineering thermoplastic with good aesthetic qualities. It's frequently used for housings of electronic devices, automotive interior parts, toys (e.g., LEGO bricks), and consumer products due to its ability to be easily molded and finished.

- Polycarbonate (PC): A high-performance, strong, and exceptionally impact-resistant thermoplastic, often transparent. It offers good heat resistance and dimensional stability, making it suitable for applications like lenses, safety glasses, electronic enclosures, and automotive components.

- Polyethylene (PE): Available in various densities (HDPE, LDPE, LLDPE), polyethylene is known for its flexibility, chemical resistance, and good electrical insulation properties. It's commonly used for bottles, containers, bags, and pipes.

- Nylon (Polyamide - PA): A strong, durable engineering plastic with good wear resistance, chemical resistance, and high-temperature performance. It's often reinforced with glass fibers for increased strength and used in automotive parts (e.g., engine components, connectors), gears, and bearings.

- Polystyrene (PS): Comes in general-purpose (GPPS, clear and brittle) and high-impact (HIPS, opaque and tougher) grades. It's inexpensive and used for disposable cutlery, CD cases, and appliance housings.

- Polyvinyl Chloride (PVC): A durable and versatile material, available in rigid and flexible forms. It offers good chemical resistance and is used in pipes, fittings, window frames, and medical devices.

- Thermoplastic Elastomers (TPE/TPR): These materials combine the properties of rubber and plastic, offering flexibility, good grip, and shock absorption. They are used for soft-touch grips, seals, gaskets, and overmolded components.

Cost Analysis of China Injection Molding

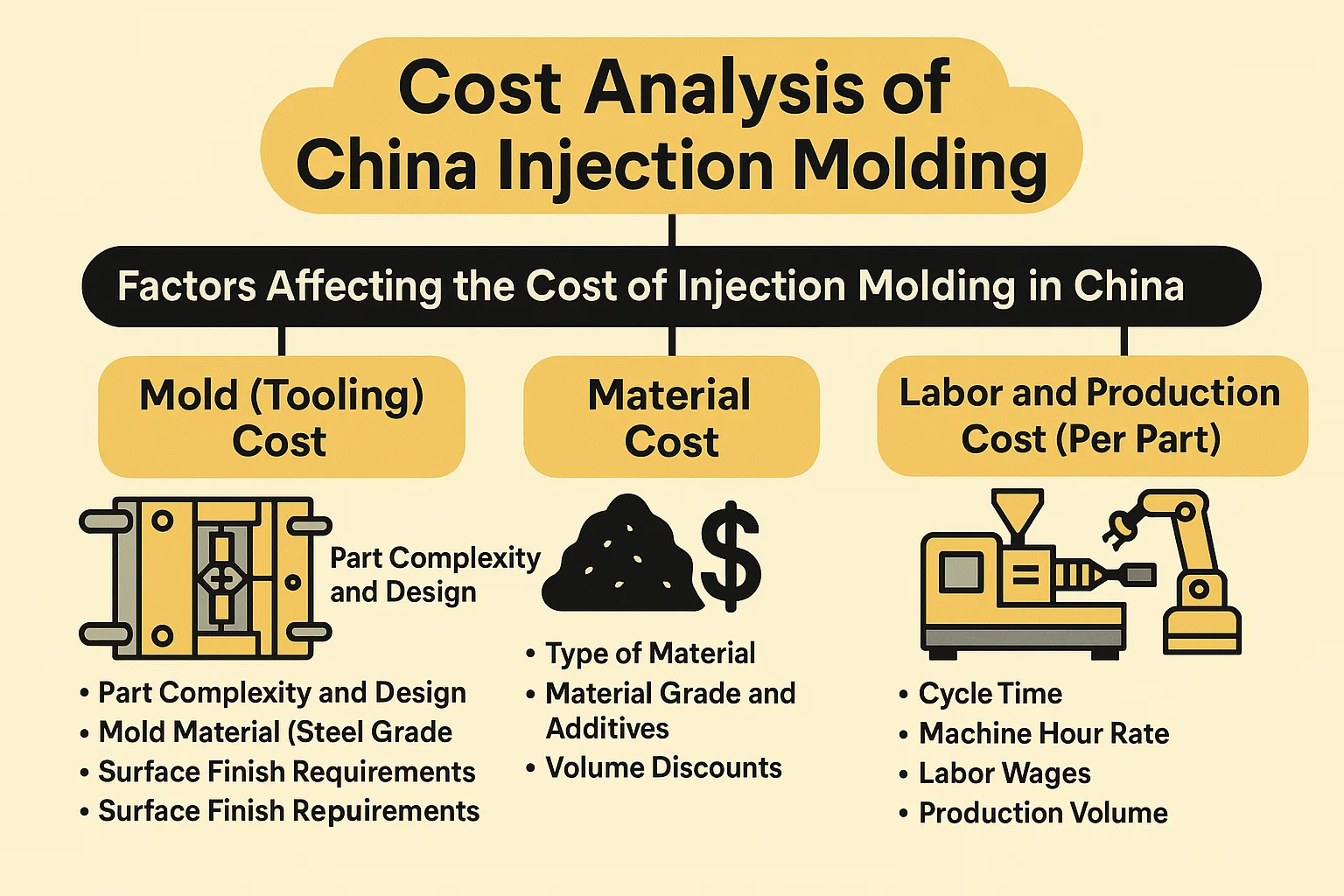

One of the primary motivations for companies to choose China for injection molding is the perceived cost advantage. While China generally offers more competitive pricing than many Western countries, understanding the various factors that contribute to the overall cost is crucial for accurate budgeting and avoiding unexpected expenses. The total cost of an injection molding project can be broadly categorized into mold (tooling) cost, material cost, and production (labor/machine) cost.

Factors Affecting the Cost of Injection Molding in China:

-

Mold (Tooling) Cost: This is often the most significant upfront investment and can range dramatically.

- Part Complexity and Design: Simple parts with uniform wall thickness, minimal undercuts, and straightforward geometries require less complex molds, leading to lower tooling costs. Conversely, intricate parts with fine details, tight tolerances, multiple undercuts requiring side actions or lifters, and complex textures will necessitate more sophisticated and expensive molds, often requiring more advanced machining (e.g., EDM) and longer build times.

- Mold Material (Steel Grade): The type of steel used for the mold directly impacts its cost and lifespan.

- P20, 718H: These are common choices for prototype molds or lower-volume production, offering a good balance of cost and performance.

- NAK80, H13: Hardened steels like these are significantly more expensive but offer superior durability, heat resistance, and surface finish capabilities, making them ideal for high-volume, long-life production molds.

- Number of Cavities: A mold can have a single cavity (producing one part per cycle) or multiple cavities (producing several parts per cycle). Multi-cavity molds have a higher initial tooling cost but dramatically reduce the per-part production cost by increasing output per cycle, making them cost-effective for high-volume runs.

- Mold Base and Components: The size of the mold, the type of runner system (hot runner vs. cold runner), and the quality of standard mold components (ejector pins, slides, etc.) all contribute to the tooling cost. Hot runner molds, while more expensive initially, save on material waste and cycle time, leading to lower per-part costs in high volume.

- Surface Finish Requirements: Highly polished surfaces (e.g., SPI A-1 finish) or complex textures require more intensive labor and specialized tooling techniques, adding to the mold cost.

- Mold Life Expectancy: Manufacturers design molds for a specific number of cycles (shots). A mold designed for a higher lifespan (e.g., 1 million shots) will be built with more robust materials and precision, incurring a higher cost than a mold designed for 50,000 shots.

-

Material Cost: The cost of the plastic resin itself is a direct and often significant component of the per-part cost.

- Type of Material: As discussed, commodity plastics like PP or ABS are significantly less expensive per kilogram than engineering plastics like PC, Nylon, or high-performance polymers (e.g., PEEK, Ultem).

- Material Grade and Additives: Virgin materials are more expensive than recycled grades. The inclusion of additives such as UV stabilizers, flame retardants, glass fibers (for strength), colorants (especially custom colors, white, or transparent), or special functional additives will increase material costs.

- Volume Discounts: Larger material purchases for high-volume production can often secure better pricing from suppliers.

- Market Fluctuations: Global resin prices are subject to market demand, oil prices, and supply chain dynamics, which can impact the per-part cost over time.

-

Labor and Production Cost (Per Part): This is the cost associated with running the injection molding machines and the labor involved.

- Cycle Time: The time it takes to produce one part (or one shot from a multi-cavity mold) is a critical cost driver. Shorter cycle times mean more parts can be produced per hour, reducing the per-part cost. Factors like part design (wall thickness), material properties, mold cooling efficiency, and machine capabilities influence cycle time.

- Machine Hour Rate: This includes the cost of electricity, machine depreciation, maintenance, and overhead allocated to the machine's operating time. Larger, more sophisticated machines typically have higher hourly rates.

- Labor Wages: China's labor costs, while rising, are still significantly lower than those in many Western countries. This is a key factor in the overall cost advantage.

- Production Volume: This is arguably the most impactful factor on per-part cost.

- Economies of Scale: Fixed costs (like tooling) are amortized over the total number of parts produced. The higher the production volume, the lower the per-part cost for both tooling and setup.

- Setup and Changeover: Each time a mold is changed or a new production run is set up, there are costs associated with machine downtime and labor. Higher volumes reduce the frequency of these changeovers, optimizing efficiency.

- Post-Processing: Any secondary operations like deburring, assembly, painting, printing, or specialized packaging will add to the per-part cost.

Comparing Costs with Other Countries:

China has historically offered significant cost advantages in injection molding, particularly for medium to high-volume production.

- China vs. Western Countries (e.g., USA, Europe): Chinese injection molding costs are typically 20-50% lower than in the United States and 30-60% lower than in Europe. This gap is primarily driven by:

- Lower Labor Costs: Skilled labor in China still commands lower wages.

- Competitive Tooling: The cost of designing and manufacturing molds in China is generally much lower due to efficient tooling shops, lower material costs (especially for tool steel), and competitive wages for mold makers.

- Economies of Scale: China's vast manufacturing capacity allows for large-scale production, which further reduces per-unit costs.

- Integrated Supply Chain: A mature and interconnected supply chain for raw materials, machinery, and ancillary services helps keep costs down.

- China vs. Emerging Economies (e.g., Vietnam, India, Mexico): While countries like Vietnam, India, and Mexico are emerging as lower-cost alternatives, especially for certain product types or for companies seeking regional diversification, China often still maintains an edge in:

- Tooling Sophistication and Capability: For complex molds and high-precision parts, China's tooling expertise is generally more advanced.

- Supply Chain Maturity: China's well-established and extensive supply chain for injection molding is hard to match.

- Scalability: For very high-volume projects, China's capacity and efficiency are often superior.

- Rising Costs in China: It's important to note that labor costs in China have been steadily rising, and factors like tariffs and geopolitical considerations can impact the overall cost equation. However, for many projects, especially those requiring complex tooling or large volumes, China remains highly competitive.

Tips for Reducing Injection Molding Costs:

- Optimize Part Design for Manufacturability (DFM):

- Simplify Geometry: Reduce complex features, undercuts, and unnecessary intricacies.

- Maintain Uniform Wall Thickness: This promotes consistent cooling, reduces cycle time, prevents warping and sink marks, and simplifies mold design.

- Add Draft Angles: Ensure adequate draft (taper) on all vertical walls to allow for easy part ejection, reducing ejection force and potential damage, and avoiding costly mold modifications.

- Incorporate Ribs and Gussets: Instead of increasing wall thickness for strength, use ribs and gussets to add rigidity while minimizing material use and cooling time.

- Consider Self-Mating or Universal Parts: Designing parts that can be used interchangeably (e.g., a top and bottom that are identical) can reduce the number of unique molds needed.

- Strategic Material Selection:

- Choose Standard Materials: Opt for commonly available and less expensive resins like PP or ABS unless specific performance requirements necessitate engineering or high-performance plastics.

- Minimize Color Changes: Using "natural" or black resin is often the cheapest. Custom or unique colors add cost due to colorant expenses and machine cleaning between runs.

- Consider Recycled Content: If suitable for your application, using recycled thermoplastics can reduce material costs.

- Optimize Production Volume:

- Match Cavitation to Volume: For very high volumes, invest in a multi-cavity mold to reduce per-part cost. For lower volumes, a single-cavity mold or even a rapid prototype mold (e.g., aluminum) might be more cost-effective.

- Consolidate Orders: If you have multiple parts, producing them concurrently or consolidating orders can leverage economies of scale for materials and production.

- Work Closely with Your Supplier on Tooling:

- Discuss Mold Material: Understand the trade-offs between mold cost and lifespan based on your projected production volume.

- Consider Hot vs. Cold Runner: For high volumes, the initial higher cost of a hot runner mold can be quickly offset by material savings and faster cycle times.

- Negotiate Tooling Ownership: Clarify who owns the mold and the terms for its maintenance and storage.

- Effective Communication and Quality Control:

- Provide Clear Specifications: Detailed 2D drawings with tolerances and 3D CAD models are essential to avoid misinterpretations and costly rework.

- Implement Robust Quality Checks: Proactive quality control can prevent expensive scrap, rework, and shipping of defective parts.

- Streamline Logistics and Packaging:

- Optimize Shipping Methods: Balance speed (air freight) with cost (sea freight) based on your timeline.

- Simple Packaging: Standard bulk packaging is cheaper than custom retail packaging.

Quality Control in China Injection Molding

While cost-effectiveness is a major draw for China injection molding, achieving and maintaining high product quality is paramount. Without rigorous quality control (QC), even the lowest prices can lead to significant losses through defective products, customer dissatisfaction, brand damage, and costly rework or recalls. Understanding how quality is managed, what issues to look for, and the certifications to seek out is essential for a successful manufacturing partnership.

Importance of Quality Control:

Quality control is not merely an afterthought; it's an integral part of the entire manufacturing lifecycle, from design to delivery. Its importance cannot be overstated in injection molding, especially when outsourcing:

- Ensuring Product Reliability and Performance: Consistent quality ensures that each part functions as intended, meets design specifications, and performs reliably in its end application.

- Minimizing Defects and Waste: Effective QC identifies issues early in the process, preventing the production of large batches of defective parts, thereby reducing material waste, energy consumption, and rework costs.

- Maintaining Brand Reputation: High-quality products build customer trust and loyalty, enhancing your brand's image and market standing. Conversely, quality failures can quickly tarnish a reputation.

- Meeting Industry Standards and Regulations: Many industries (e.g., medical, automotive, aerospace) have strict regulatory requirements that molded parts must meet. QC ensures compliance.

- Cost Savings in the Long Run: While implementing QC measures has an upfront cost, it saves significantly more by preventing costly recalls, warranty claims, returns, and the need to scrap and remanufacture parts.

- Predictable Production: A robust QC system leads to more predictable production outcomes, fewer delays, and more reliable delivery schedules.

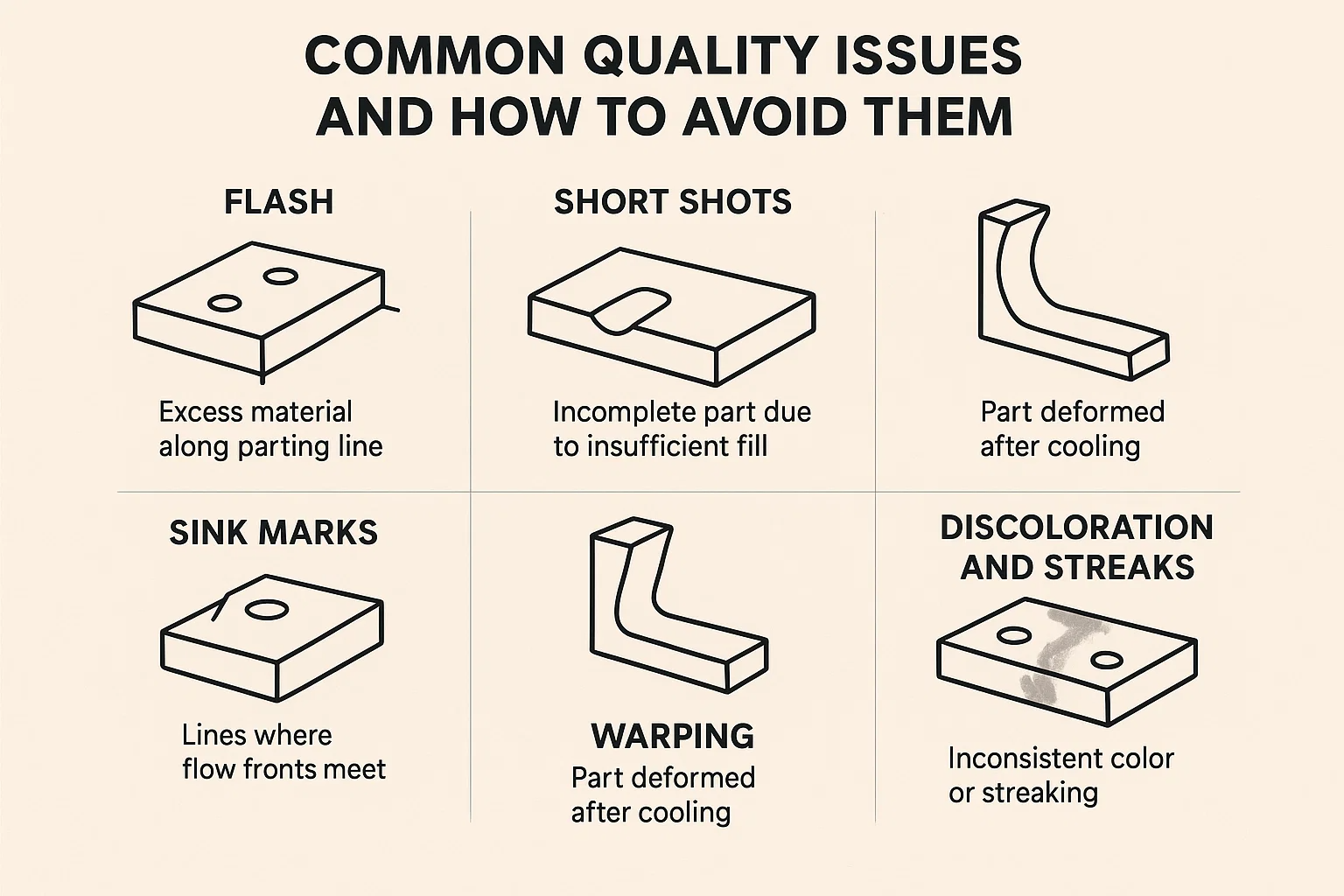

Common Quality Issues and How to Avoid Them:

Despite the precision of injection molding, various defects can occur. Recognizing these and understanding their causes is key to prevention and effective problem-solving with your Chinese manufacturer.

-

Flash (or Burrs):

- Description: Excess material seeping out of the mold cavity, forming a thin, undesirable layer along the part's parting line.

- Causes: Too much injection pressure or speed, insufficient clamping force, worn-out molds, mold misalignment, or poor mold design (e.g., improper sealing).

- Avoidance: Optimize injection parameters (pressure, speed), ensure adequate clamping force, regular mold maintenance and inspection, and precise mold design.

-

Short Shots (or Non-Fills):

- Description: An incomplete part where the molten plastic did not fully fill the mold cavity, resulting in missing sections.

- Causes: Insufficient material injected, low injection pressure/speed, material viscosity too high, mold temperature too low, or trapped air/insufficient venting.

- Avoidance: Increase shot size, increase injection pressure/speed, ensure proper melt temperature, optimize mold temperature, improve mold venting, or consider gate location changes.

-

Sink Marks:

- Description: Depressions or shallow craters on the surface of a molded part, usually in thicker sections.

- Causes: Uneven cooling of the plastic, especially when thicker sections cool slower and shrink inward, or insufficient packing/holding pressure.

- Avoidance: Design parts with uniform wall thickness, increase holding pressure and time, lower melt or mold temperature slightly, or redesign the part to reduce thick sections.

-

Warping (or Distortion):

- Description: Deformed or twisted parts that do not retain their intended shape after cooling.

- Causes: Uneven cooling rates throughout the part, internal stresses from material shrinkage, or improper mold design (e.g., lack of uniform wall thickness, insufficient cooling channels).

- Avoidance: Ensure uniform cooling and mold temperature, optimize cooling time, design parts with consistent wall thickness, or consider material changes with lower shrinkage rates.

-

Weld Lines (or Knit Lines):

- Description: Visible lines or notches where two or more flow fronts of molten plastic meet and re-solidify, often around holes or inserts. These can be cosmetic or a structural weakness.

- Causes: Molten plastic solidifying before fully blending, low melt or mold temperature, or poor gate placement.

- Avoidance: Increase melt/mold temperature, increase injection speed, optimize gate location to minimize flow paths, or use materials with better flow characteristics.

-

Discoloration and Streaks:

- Description: Inconsistent color, streaking, or blotches on the part surface.

- Causes: Contamination in the raw material, improper mixing of colorants, material degradation due to excessive heat, or residue in the machine barrel/nozzle.

- Avoidance: Ensure raw material cleanliness, proper drying of hygroscopic materials, precise colorant dosing, optimized melt temperature control, and regular machine cleaning.

-

Voids (or Bubbles):

- Description: Trapped air bubbles or empty pockets within the molded part.

- Causes: Insufficient packing pressure, trapped gases from moisture or material degradation, or rapid cooling that seals off the outer skin before the core can solidify.

- Avoidance: Increase packing pressure, ensure proper material drying, improve mold venting, or optimize cooling rates.

Quality Control Measures and Certifications:

Reputable Chinese injection molding manufacturers implement comprehensive QC measures throughout the entire production process. When vetting suppliers, look for evidence of the following:

-

Design for Manufacturability (DFM) Review: QC starts at the design phase. A good manufacturer will review your part design for potential molding issues (e.g., wall thickness, draft angles, undercuts) before mold fabrication, preventing costly errors down the line.

-

Incoming Material Inspection (IQC):

- Verification of raw material (resin) against specifications (e.g., Material Safety Data Sheet - MSDS, Certificate of Analysis - COA).

- Checking for proper drying of hygroscopic materials, as moisture can cause defects.

-

Mold/Tooling Inspection:

- Thorough inspection of the fabricated mold before production runs, including dimensional checks, surface finish verification, and functionality tests (e.g., hot runner system, ejection mechanism).

- First Article Inspection (FAI): Producing a small batch of parts (the "first article") from the new mold and performing a detailed dimensional inspection and functional test. This is a critical step to verify the mold's accuracy before mass production.

-

In-Process Quality Control (IPQC):

- Parameter Monitoring: Continuous monitoring and control of critical molding parameters (temperature, pressure, cycle time, injection speed) using statistical process control (SPC) techniques to ensure consistency.

- Visual Inspections: Regular visual checks by operators for defects like flash, discoloration, or short shots.

- Dimensional Checks: Periodic dimensional measurements of parts during production using calipers, micrometers, CMM (Coordinate Measuring Machine), or optical comparators to ensure they remain within specified tolerances.

- Sampling: Implementing a defined sampling plan (e.g., AQL - Acceptable Quality Limit) to inspect a subset of parts at regular intervals.

-

Final Quality Control (FQC) / Pre-Shipment Inspection:

- A final, comprehensive inspection of the finished products before packaging and shipment. This includes visual, dimensional, and often functional testing.

- Verification of packaging and labeling.

- Often, third-party inspection agencies are employed at this stage for an unbiased assessment.

Certifications:

Certifications demonstrate a manufacturer's commitment to established quality management systems and specific industry standards.

- ISO 9001: This is the most common and fundamental international standard for quality management systems (QMS). An ISO 9001 certified company has a documented system in place for managing its processes, ensuring consistency, customer satisfaction, and continuous improvement. It is a baseline expectation for any reputable Chinese manufacturer.

- ISO/TS 16949 (now IATF 16949): This is a specific quality management standard for the automotive industry. Manufacturers with this certification are highly experienced in stringent quality requirements, process controls, and continuous improvement, making them ideal partners for automotive components.

- ISO 13485: This standard specifies requirements for a comprehensive quality management system for the design and manufacture of medical

devices. If your product is a medical device, this certification is non-negotiable. - CE, RoHS, REACH, FDA, etc.: These are product-specific compliance certifications relevant to certain markets or material restrictions. While not directly a QMS certification, a manufacturer's familiarity with these standards and ability to produce compliant parts is a strong indicator of their quality capabilities.

Finding the Right China Injection Molding Partner

Identifying and securing a reliable and competent injection molding partner in China is arguably the most crucial step for the success of your project. The market is vast, with thousands of suppliers ranging from small workshops to large, highly automated factories. Navigating this landscape requires a strategic approach, thorough due diligence, and an understanding of effective communication and cultural nuances.

Where to Find Injection Molding Companies in China:

There are several avenues to explore when searching for potential manufacturing partners:

-

Online B2B Platforms and Directories: These are often the first stop for many businesses due to their extensive databases and accessibility.

- Alibaba.com: The largest global B2B marketplace, offering a vast selection of manufacturers. Use filters for "Verified Supplier," "Trade Assurance," and specific product categories to narrow your search. Review supplier profiles, transaction history, and customer reviews.

- Global Sources (globalsources.com): Similar to Alibaba, with a strong focus on electronics, components, and more specialized industries. Known for more detailed company profiles.

- Made-in-China.com: Another prominent platform offering a wide range of suppliers across various industries, including plastics and molding.

- Specialized Manufacturing Directories: Some websites or industry associations may offer more curated lists of manufacturers specifically focused on injection molding or your particular product type.

- Managed Sourcing Services: Companies like Xometry or Sourcing Allies offer managed services where they have a vetted network of Chinese suppliers and handle the communication and project management on your behalf, which can be beneficial for those new to sourcing in China or with limited resources.

-

Trade Shows: Attending trade shows in China offers an unparalleled opportunity for face-to-face interaction, factory visits, and directly assessing capabilities.

- CHINAPLAS: This is arguably the world's leading plastics and rubber trade fair, held annually in China (alternating between Shenzhen and Shanghai). It's an essential event for discovering new technologies, materials, and connecting with a vast number of injection molding machinery manufacturers and service providers.

- DIE & MOULD CHINA: Another significant exhibition focusing specifically on mold and die manufacturing, which is integral to injection molding.

- Canton Fair (China Import and Export Fair): While a broader exhibition covering almost all product categories, the Canton Fair often has a significant section dedicated to machinery and industrial products where injection molding companies exhibit.

- Industry-Specific Fairs: Depending on your product (e.g., automotive parts, medical devices), there might be specialized trade shows in China where you can find manufacturers with relevant expertise and certifications.

-

Referrals and Networks:

- Industry Connections: Leverage your professional network. Ask colleagues, industry peers, or consultants for recommendations based on their positive experiences.

- Sourcing Agents/Consultants: Experienced sourcing agents or consultants with a strong presence and network in China can provide invaluable assistance. They often have pre-vetted lists of reliable suppliers and can bridge cultural and communication gaps.

Due Diligence: Verifying the Supplier's Capabilities and Experience:

Once you have a list of potential partners, rigorous due diligence is critical. Do not rely solely on online profiles.

-

Request Comprehensive Company Information:

- Business License and Registration: Request a copy of their official business license. Verify its legitimacy through official Chinese government databases (e.g., National Enterprise Credit Information Publicity System - NECIPS). This confirms they are a legally registered entity.

- Certifications: Ask for copies of relevant certifications (ISO 9001, ISO 13485, IATF 16949, etc.) and verify their authenticity with the issuing bodies if possible.

- Export License: Ensure they have the necessary licenses to export goods from China.

- Company Profile and History: Understand their years in business, company size, number of employees, and main markets served. Longer operating history often indicates stability.

-

Assess Manufacturing Capabilities:

- Equipment List: Request a detailed list of their machinery, including injection molding machine tonnages, brands, and ages. This indicates their capacity and ability to handle your part size.

- Tooling Capabilities: Ask if they have in-house mold design and manufacturing capabilities or if they outsource. In-house tooling often provides better control over quality and lead times.

- Production Capacity: Discuss their daily/monthly production capacity relevant to your project volume.

- Material Experience: Confirm their experience with the specific plastic materials you plan to use.

- Secondary Operations: Inquire about their capabilities for post-molding processes like assembly, painting, printing, ultrasonic welding, etc., if needed.

- Sample Parts: Request samples of parts they have previously molded (ideally similar in complexity or material to yours). This gives you a tangible sense of their quality.

-

Evaluate Quality Control Systems:

- QMS Documentation: Ask for their Quality Management System (QMS) manual or procedures, especially related to incoming material inspection, in-process control, and final inspection.

- Inspection Equipment: Inquire about their inspection tools (CMM, calipers, gauges, optical comparators).

- Traceability: Understand their system for tracking materials and production batches.

- Defect Management: How do they identify, document, and resolve quality issues?

- Third-Party Audits: Consider hiring a third-party inspection company to conduct a factory audit. This provides an objective assessment of their facilities, processes, and quality systems.

-

Financial Stability Check (if possible): While harder to obtain directly, a financially stable supplier is less likely to cease operations mid-project. A sourcing agent or trade credit agency might be able to provide some insights.

-

References: Request references from existing or past international clients, and actually contact them to inquire about their experience regarding quality, delivery, communication, and problem-solving.

Communication and Cultural Considerations:

Effective communication is paramount to success and overcoming potential challenges when working with Chinese manufacturers.

-

Language Barriers:

- English Proficiency: While many Chinese business professionals speak English, proficiency levels vary. Use clear, concise language. Avoid slang, jargon, and overly complex sentences.

- Written Communication: Prefer written communication (email, WeChat messages) to ensure a clear record of discussions and decisions. Use bullet points and numbered lists for clarity.

- Visuals: Utilize 3D CAD models, detailed 2D drawings with tolerances, annotated photos, and videos to convey information precisely. "A picture is worth a thousand words" is particularly true here.

- Dedicated Contact Person: Aim to establish a relationship with a specific, English-speaking contact person who is responsible for your project.

-

Cultural Nuances:

- Guanxi (Relationships): In China, relationships are highly valued in business. Investing time in building trust and rapport ("Guanxi") can lead to smoother operations, greater flexibility, and better outcomes. This can involve regular communication, showing respect, and sometimes even social engagements.

- "Saving Face" (Mianzi): This concept is crucial. Chinese business culture often avoids direct "no" or open confrontation to avoid causing anyone to "lose face" (embarrassment, loss of dignity, or reputation).

- Implications: A "yes" might sometimes mean "maybe," "I understand the question," or "I will try." It doesn't always guarantee capability or agreement.

- Strategy: Be patient and confirm understanding. Ask open-ended questions. Instead of "Can you do this?", try "How will you achieve X?" or "What challenges do you foresee with Y?" Look for detailed explanations and actionable plans rather than just a simple affirmation. Avoid publicly criticizing or directly challenging your contact; provide feedback constructively and privately.

- Hierarchy: Respect the chain of command. Decisions often come from higher up. Understand who the decision-makers are and try to build rapport with them.

- Patience and Long-Term View: Building a successful manufacturing relationship in China often takes time. Be patient, invest in the relationship, and focus on long-term mutual benefit rather than purely transactional interactions.

- Negotiation Style: Be prepared for a different negotiation style. Sometimes initial quotes may be high, expecting negotiation. Focus on win-win outcomes.

Prototyping and Tooling

Before diving into mass production, two critical stages in the injection molding journey are prototyping and tooling. These phases are instrumental in validating your design, ensuring manufacturability, and preparing for efficient, high-quality production.

The Role of Prototyping in Injection Molding:

Prototyping is the creation of preliminary physical models of your product or its components. For injection molding, prototypes serve several vital functions:

-

Design Validation and Refinement:

- Form, Fit, and Function (FFF): Prototypes allow you to physically assess whether your part's dimensions, shape, and features are correct, if it fits with other components in an assembly, and if it performs its intended function in a real-world environment.

- Early Defect Detection: Many design flaws or issues related to assembly, ergonomics, or structural integrity are only evident in a physical model, not on a screen. Catching these early saves immense time and cost downstream.

- Aesthetic Evaluation: Prototypes provide a tangible representation of the product's appearance, allowing for aesthetic adjustments before committing to expensive production tooling.

-

Cost Efficiency:

- Avoiding Costly Rework: Modifying a finished production mold is extremely expensive and time-consuming. Prototyping identifies design issues upfront, allowing for low-cost digital or rapid prototype adjustments before the mold is cut. "Fail early, fail cheap."

- Material and Process Testing: While often not made from the final production material or with a production mold, prototypes can help validate aspects of material behavior or highlight potential molding challenges.

-

Accelerated Time-to-Market: By streamlining the design validation process, prototyping helps to reduce overall product development cycles, allowing you to bring your product to market faster.

-

Improved Communication and Collaboration: A physical prototype serves as a universal language among designers, engineers, marketing teams, and stakeholders. It facilitates clearer discussions, aligns expectations, and ensures everyone is on the same page about the final product.

Prototyping Methods (Pre-Injection Molding):

While "prototype injection molding" (using aluminum or soft steel tools for low-volume runs) exists, earlier stages of prototyping often use other methods:

- 3D Printing (Additive Manufacturing):

- Advantages: Extremely fast, cost-effective for single units or very low volumes, allows for complex geometries, and iterative design changes are quick.

- Disadvantages: Material properties typically do not replicate actual injection molding resins (e.g., strength, surface finish, thermal properties), not suitable for high volumes, and cannot truly validate the injection molding process itself. Best for early form and fit checks.

- CNC Machining:

- Advantages: Can achieve high precision, works with a wider range of engineering-grade plastics that are closer to final production materials.

- Disadvantages: More expensive and slower than 3D printing, especially for complex parts; still doesn't fully replicate the stress/flow of injection molding.

- Vacuum Casting (Urethane Casting):

- Advantages: Good for producing small batches (10-50 units) of parts that closely simulate injection molded parts in terms of appearance and certain mechanical properties, using silicone molds from a master pattern.

- Disadvantages: Not actual injection molding materials, can have limitations in part size and complexity, and is for very low volume only.

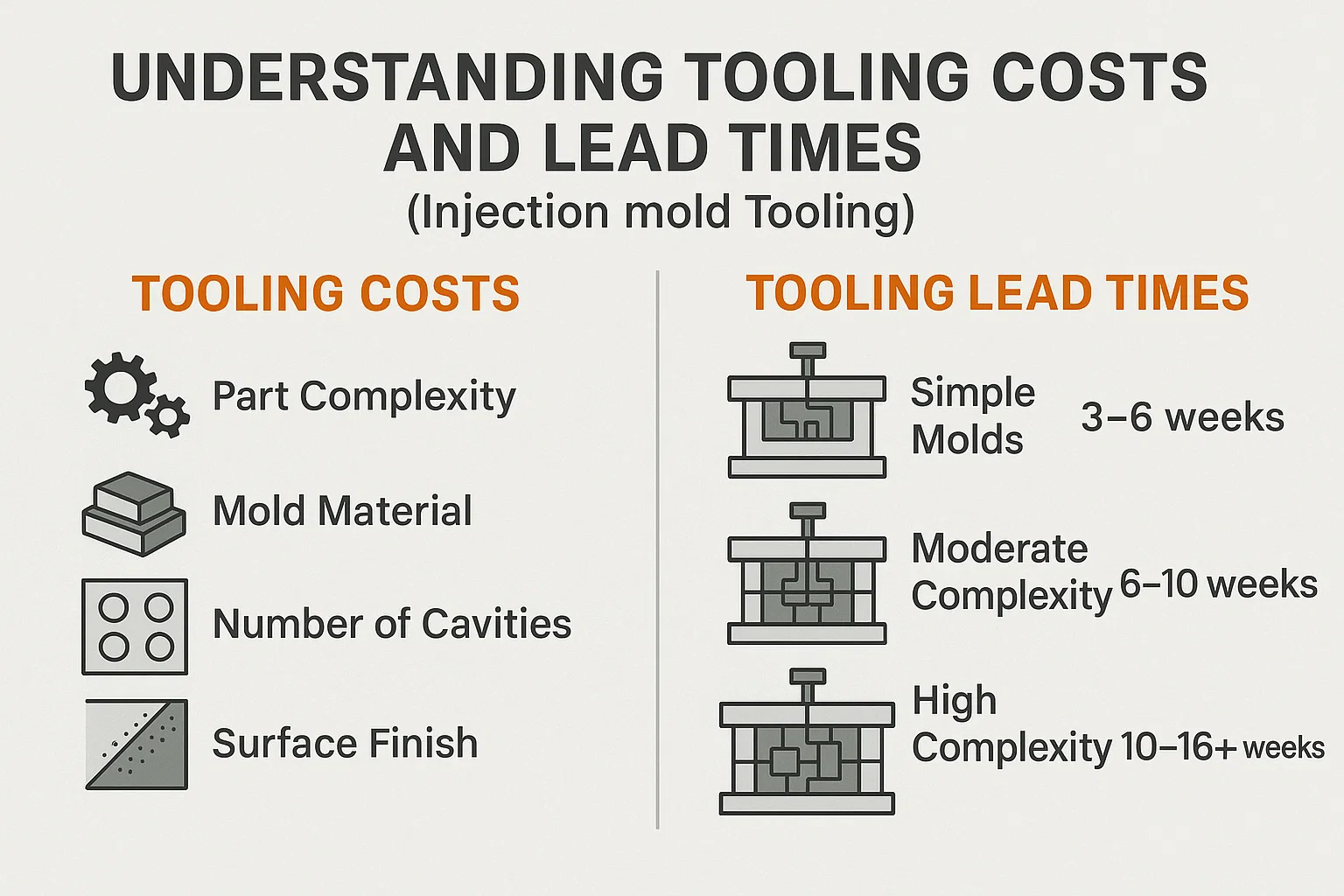

Understanding Tooling Costs and Lead Times (Injection Mold Tooling):

Tooling, or mold fabrication, is the most significant upfront investment in injection molding. Understanding its costs and lead times is crucial for project planning and budgeting.

Tooling Costs:

As previously discussed in the cost analysis, mold costs are influenced by:

- Part Complexity: Intricate designs with tight tolerances, internal features, undercuts (requiring slides/lifters), or fine textures demand more complex and expensive mold designs and machining processes (e.g., EDM, wire cutting).

- Mold Material:

- Aluminum (e.g., 7075-T6): Less expensive, faster to machine, suitable for prototyping or low-volume production (e.g., 1,000 to 10,000 shots). Softer, so wear can be an issue for high volumes.

- P20 Steel (Pre-hardened): A common balance of cost and durability, good for medium-volume production (e.g., 10,000 to 100,000 shots).

- Hardened Steel (e.g., H13, S7, NAK80): Most expensive, but offers superior hardness, wear resistance, and longevity, essential for high-volume production (e.g., 100,000 to millions of shots) and parts requiring tight tolerances or excellent surface finishes.

- Number of Cavities: More cavities increase the initial mold cost but reduce the per-part cost by accelerating production. A 4-cavity mold will be more expensive than a single-cavity mold but will produce parts four times faster.

- Hot Runner vs. Cold Runner System: Hot runner systems are more complex and costly to build but eliminate runner waste and can reduce cycle times, offering long-term savings for high-volume production. Cold runner molds are simpler and cheaper upfront.

- Surface Finish: High-gloss or textured finishes require more intricate mold polishing or etching, adding to the cost.

- Mold Size: Larger parts require larger molds, which consume more steel and require more machining time.

- Supplier's Overhead and Profit Margin: These vary between manufacturers.

Tooling Lead Times:

Lead times for mold fabrication in China can vary significantly based on complexity:

- Simple Molds (Single Cavity, Basic Geometry, Aluminum/P20 Steel): Can range from 3-6 weeks.

- Moderate Complexity (Multi-Cavity, Some Undercuts, P20 Steel): Typically 6-10 weeks.

- High Complexity (Multi-Cavity, Hot Runner, Complex Undercuts, Hardened Steel): Can take 10-16+ weeks.

These lead times include design, material acquisition, machining, assembly, and initial testing (T0 trial). It's crucial to get a clear timeline from your supplier and factor it into your overall project schedule. Delays in tooling directly impact your time-to-market.

Designing for Manufacturability (DFM) Considerations:

Designing for Manufacturability (DFM), often referred to as Design for Moldability in the context of injection molding, is the practice of optimizing a product's design to make it easier, more cost-effective, and more reliable to manufacture using a specific process. Engaging in DFM with your Chinese partner early in the design phase is paramount.

Key DFM considerations for injection molding include:

- Uniform Wall Thickness:

- Principle: Maintain consistent wall thickness throughout the part as much as possible.

- Why: Uneven wall thickness causes inconsistent cooling and shrinkage, leading to defects like warping, sink marks (depressions), and internal stresses. It also makes mold filling more challenging.

- How: If variations are unavoidable, make transitions gradual (e.g., use fillets).

- Draft Angles:

- Principle: Add a slight taper to all vertical walls (surfaces parallel to the mold's opening direction).

- Why: Allows the part to easily eject from the mold without sticking, scratching, or deforming. Without sufficient draft, parts can get stuck, requiring excessive ejection force that damages both the part and the mold.

- Recommendation: A minimum of 0.5-1 degree per side is often recommended for smooth surfaces, with more (e.g., 2-5 degrees) needed for textured surfaces or deep features.

- Radii and Fillets (Rounded Corners):

- Principle: Avoid sharp internal and external corners. Instead, use generous radii (rounded external corners) and fillets (rounded internal corners).

- Why: Sharp corners create stress concentrations (points where stress accumulates), which can lead to part breakage during ejection or in use. They also impede plastic flow, increase mold wear, and can be difficult to machine. Fillets promote smoother material flow and reduce stress.

- Recommendation: Internal radius should ideally be at least 0.5 times the wall thickness, and external radius 1.5 times the wall thickness.

- Minimizing Undercuts:

- Principle: An undercut is any feature that prevents a part from being directly pulled out of the mold along the opening direction (e.g., a hole on the side, a clip, a snap feature).

- Why: Undercuts require additional, costly mold mechanisms like slides (side actions), lifters, or core pulls to allow the part to be ejected. These add complexity, cost, and maintenance to the mold.

- How to Mitigate:

- Redesign: Can the feature be moved or redesigned to be in line with the mold's opening direction?

- Core-Pull/Slides: If essential, accept the added tooling cost and complexity.

- Bump-Offs: For very small, flexible undercuts (e.g., small barbed features), the part might deform slightly to "bump-off" the mold feature without a side action, but this needs careful design and material choice.

- Gate Location:

- Principle: Strategic placement of the gate (where plastic enters the mold cavity) is crucial.

- Why: Influences material flow, filling pattern, potential for weld lines, sink marks, and gate vestige (the small mark left where the runner is removed).

- Considerations: Typically placed in the thickest section of the part to ensure proper filling and packing, or in a non-cosmetic area. Mold flow analysis software can simulate optimal gate placement.

- Ejector Pin Placement:

- Principle: Place ejector pins in areas that won't compromise aesthetics or functionality, ideally on rigid features or where marks are acceptable.

- Why: Ensures smooth ejection without deforming or damaging the part.

- Considerations: Ensure sufficient ejector pins are used, especially near ribs or bosses, to distribute ejection force evenly.

- Ribs and Bosses:

- Principle: Use ribs to add strength and stiffness without increasing overall wall thickness. Bosses are cylindrical protrusions used for mounting, fastening, or locating.

- Why: Efficient use of material for structural integrity.

- Design: Rib thickness should typically be 40-60% of the nominal wall thickness to avoid sink marks. Bosses should be designed with sufficient draft and a cored-out center for uniform wall thickness.

- Tolerances:

- Principle: Specify tolerances only as tight as functionally necessary.

- Why: Very tight tolerances increase mold cost, tooling lead time, production difficulty, and inspection costs.

- Considerations: Discuss achievable tolerances with your manufacturer based on material, part size, and mold type.

Managing Production and Logistics

Once your mold is finalized and approved, and production begins, the focus shifts to overseeing the manufacturing process and ensuring efficient, cost-effective delivery of your finished parts. Managing production timelines, shipping, and customs can be complex, but with proper planning and communication, it's a manageable process.

Production Timelines and Lead Times:

Understanding the factors that influence production lead times is essential for setting realistic expectations and planning your supply chain.

- Tooling Lead Time (as discussed): This is the initial, often longest, lead time. Once the mold is complete and validated, actual part production can be very fast.

- Production Volume:

- Low to Medium Volume: For smaller runs (e.g., a few thousand to tens of thousands of parts), production might be completed within a few days to a couple of weeks, depending on the complexity of the part and the number of mold cavities.

- High Volume/Mass Production: For hundreds of thousands or millions of parts, production will be an ongoing process. While the cycle time per part is very fast, the overall production run could span weeks or months. Manufacturers will often schedule your production on specific machines and shifts.

- Part Complexity and Cycle Time: Simpler parts with shorter cycle times will naturally be produced faster than complex parts requiring longer cooling or intricate secondary operations.

- Material Availability: Ensure your chosen material is readily available to avoid delays. Some specialized or custom-colored materials might have longer lead times from the resin supplier to the molding factory.

- Secondary Operations: If your parts require post-molding processes like painting, printing, assembly, or specialized packaging, these will add to the overall production lead time. Ensure these are factored into the quoted timeline.

- Quality Control Procedures: The extent and rigor of in-process and final quality inspections will also influence the overall production schedule.

- Factory Load and Scheduling: The manufacturer's current production queue and capacity will play a significant role. Always discuss estimated lead times with your supplier and request a detailed production schedule.

- Holidays: Chinese national holidays (especially Chinese New Year, Golden Week, and Dragon Boat Festival) can cause significant factory shutdowns and logistical delays. Plan your production schedule around these periods.

Strategies for Managing Production Timelines:

- Clear Communication: Maintain continuous and clear communication with your supplier. Request regular updates on production status, including photos or videos of the production line.

- Detailed Production Schedule: Ask for a Gantt chart or a detailed timeline for each stage of production.

- Key Performance Indicators (KPIs): Agree on specific KPIs, such as daily production output, defect rates, and delivery dates.

- Pre-Production Meeting: Hold a thorough pre-production meeting (virtual or in-person) to review all specifications, quality standards, and timelines before production commences.

- Contingency Planning: Always build some buffer time into your schedule for unexpected delays (e.g., material shortages, machine breakdowns, quality issues, shipping delays).

Shipping and Logistics Considerations When Importing from China:

Importing goods from China involves several steps and requires careful planning to ensure your products arrive safely, on time, and within budget.

-

Incoterms (International Commercial Terms): These are globally recognized terms that clarify the responsibilities of buyers and sellers for the delivery of goods under sales contracts. Crucial for determining who pays for what and who is responsible at various stages of shipping.

- EXW (Ex Works): The buyer is responsible for all costs and risks from the factory gate onwards. Cheapest unit price from the factory, but most complex for the buyer.

- FOB (Free On Board): The seller (factory) is responsible for delivering the goods to the named port of shipment and loading them onto the vessel. The buyer assumes

costs and risks once the goods are on board. This is a very common term for sea freight. - CIF (Cost, Insurance, and Freight) / CFR (Cost and Freight): The seller pays for the cost of transport and insurance (CIF) or just transport (CFR) to the named port of destination. Risk transfers to the buyer once goods are loaded onto the vessel at the port of origin. Less control for the buyer.

- DDP (Delivered Duty Paid): The seller is responsible for all costs and risks, including customs clearance and import duties, until the goods are delivered to the buyer's specified destination. Most convenient for the buyer, but the seller's price will be higher.

- Recommendation: For most businesses, FOB is a good balance, offering cost control while having the factory handle the initial leg. If you are new to importing, DDP offers simplicity but often at a higher cost passed on by the supplier.

-

Choosing a Shipping Method:

- Sea Freight (Ocean Freight):

- Advantages: Most cost-effective for large volumes, heavy, or bulky goods. Environmentally friendlier.

- Disadvantages: Long transit times (typically 3-6 weeks to North America/Europe, plus customs clearance). Less flexible.

- FCL (Full Container Load): You pay for and use an entire shipping container (20ft or 40ft). Most cost-effective per unit for large volumes.

- LCL (Less than Container Load): Your goods share container space with other shipments. Cost-effective for smaller volumes that aren't enough to fill a whole container, but often with slightly longer transit and handling times.

- Air Freight:

- Advantages: Fastest transit time (typically 3-7 days). Ideal for urgent shipments, high-value goods, or small, lightweight items.

- Disadvantages: Significantly more expensive than sea freight. Costs are based on weight or volumetric weight, whichever is greater.

- Express Courier (e.g., DHL, FedEx, UPS):

- Advantages: Fastest (1-5 days), door-to-door service, often handles customs clearance for you. Ideal for samples, prototypes, or very small, urgent shipments.

- Disadvantages: Most expensive, unsuitable for larger or heavier shipments due to cost.

- Sea Freight (Ocean Freight):

-

Freight Forwarders:

- Role: Freight forwarders are logistics experts who handle the complexities of international shipping. They book cargo space, prepare documentation, manage customs clearance, and arrange inland transportation.

- Benefits: Simplify the process, often negotiate better rates due to bulk volume, and provide expertise in navigating regulations.

- Recommendation: Unless you have significant experience and volume, using a reputable freight forwarder (either based in China or your home country) is highly recommended.

-

Packaging:

- Importance: Proper packaging is crucial to protect your parts during transit.

- Considerations: Use sturdy cartons, appropriate inner packaging (e.g., bubble wrap, foam inserts, custom trays) to prevent scratches or damage, and ensure palletization for larger shipments. Clearly label all cartons with product information, quantity, and handling instructions.

Customs and Import Duties:

Navigating customs regulations and calculating import duties is a critical, and often complex, part of importing from China.

-

Harmonized System (HS) Codes:

- Importance: Every product imported internationally is classified under a specific HS Code. This code determines the applicable import duties and regulations in the destination country.

- Action: Work with your supplier and/or freight forwarder to accurately determine the correct HS Code for your plastic injection molded parts. Incorrect classification can lead to delays, fines, or incorrect duty payments. Common HS codes for plastic products usually start with Chapter 39 (Plastics and articles thereof).

-

Customs Valuation:

- Principle: Duties are typically calculated based on the "customs value" of the goods, which usually includes the cost of the goods, sometimes inbound freight, and insurance, depending on the Incoterms.

-

Import Duties (Tariffs):

- Country-Specific: Duty rates vary significantly by the importing country and the specific HS Code.

- Trade Agreements: Check if your country has Free Trade Agreements (FTAs) with China that might reduce or eliminate duties on certain goods.

- Additional Tariffs: Be aware of any additional tariffs, such as Section 301 tariffs imposed by the US on certain Chinese goods (including many plastic products and tooling). These can significantly increase your landed cost. As of late 2024 / mid-2025, these tariffs are still in effect for many plastic injection molded goods and tooling from China to the US. It's essential to factor these into your cost calculations.

- Action: Consult your country's customs website (e.g., USITC for the United States, your national customs agency) or a customs broker to get the most up-to-date duty rates for your specific HS code and country of origin.

-

Value Added Tax (VAT) / Goods and Services Tax (GST):

- Importance: Most countries will levy a VAT or GST on imported goods, typically calculated on the customs value plus any duties. This is usually reclaimable by VAT-registered businesses.

-

Required Documentation:

- Commercial Invoice: Essential document detailing the transaction, including seller/buyer info, product description, quantity, unit price, total value, and Incoterms.

- Packing List: Itemizes the contents of each package, including weights and dimensions.

- Bill of Lading (for sea freight) / Air Waybill (for air freight): The contract of carriage and receipt of goods.

- Certificate of Origin: Confirms the country where the goods were manufactured, important for duties and trade agreements.

- Other Certifications: Depending on the product, you may need material certifications, safety compliance documents (e.g., CE, RoHS, FDA), or test reports.

-

Customs Brokers:

- Role: Licensed professionals who specialize in customs clearance. They prepare and submit documentation, calculate duties, and communicate with customs authorities on your behalf.

- Benefits: Crucial for navigating complex customs regulations, avoiding delays, and ensuring compliance. Highly recommended unless you have in-house expertise.

English

English bahasa Indonesia

bahasa Indonesia