In the dynamic world of manufacturing, the demand for products that are both functionally superior and aesthetically pleasing has driven significant innovation. Modern components must often combine multiple materials—a rigid plastic for structure, a soft elastomer for grip, or two different colors for branding—within a single, seamless design. While traditional methods rely on separate production and assembly steps, a more advanced solution has emerged to streamline this process: 2-shot injection molding.

Introduction to 2-Shot Injection Molding

What is 2-Shot Injection Molding?

At its core, 2-shot injection molding (also known as two-shot molding) is a highly specialized manufacturing process that produces a single, finished component from two different materials in a single, continuous molding cycle. Unlike traditional methods where multiple parts are molded separately and then assembled, 2-shot molding combines these steps into one efficient operation. This process is instrumental in creating parts with complex geometries, integrated seals, multi-color aesthetics, and enhanced functionality without the need for secondary assembly.

Synonyms: Multi-Shot Molding and Overmolding

While often used interchangeably, the terms multi-shot molding and overmolding have distinct meanings that are important to understand.

-

Multi-Shot Molding: This is a broad category of which 2-shot molding is the most common form. It refers to any injection molding process that uses two or more separate injections of different materials into the same mold to create a single part. A 3-shot or 4-shot process would also fall under this umbrella.

-

Overmolding: This is a specific technique where a second material is injected over a pre-existing part (the "substrate"). While 2-shot molding is a type of overmolding, the term can also describe processes where the substrate part was made separately and is then manually or robotically placed into a second mold for the overmolding step. The key difference is that in a true 2-shot process, both materials are molded sequentially within the same machine cycle, without the part ever leaving the machine.

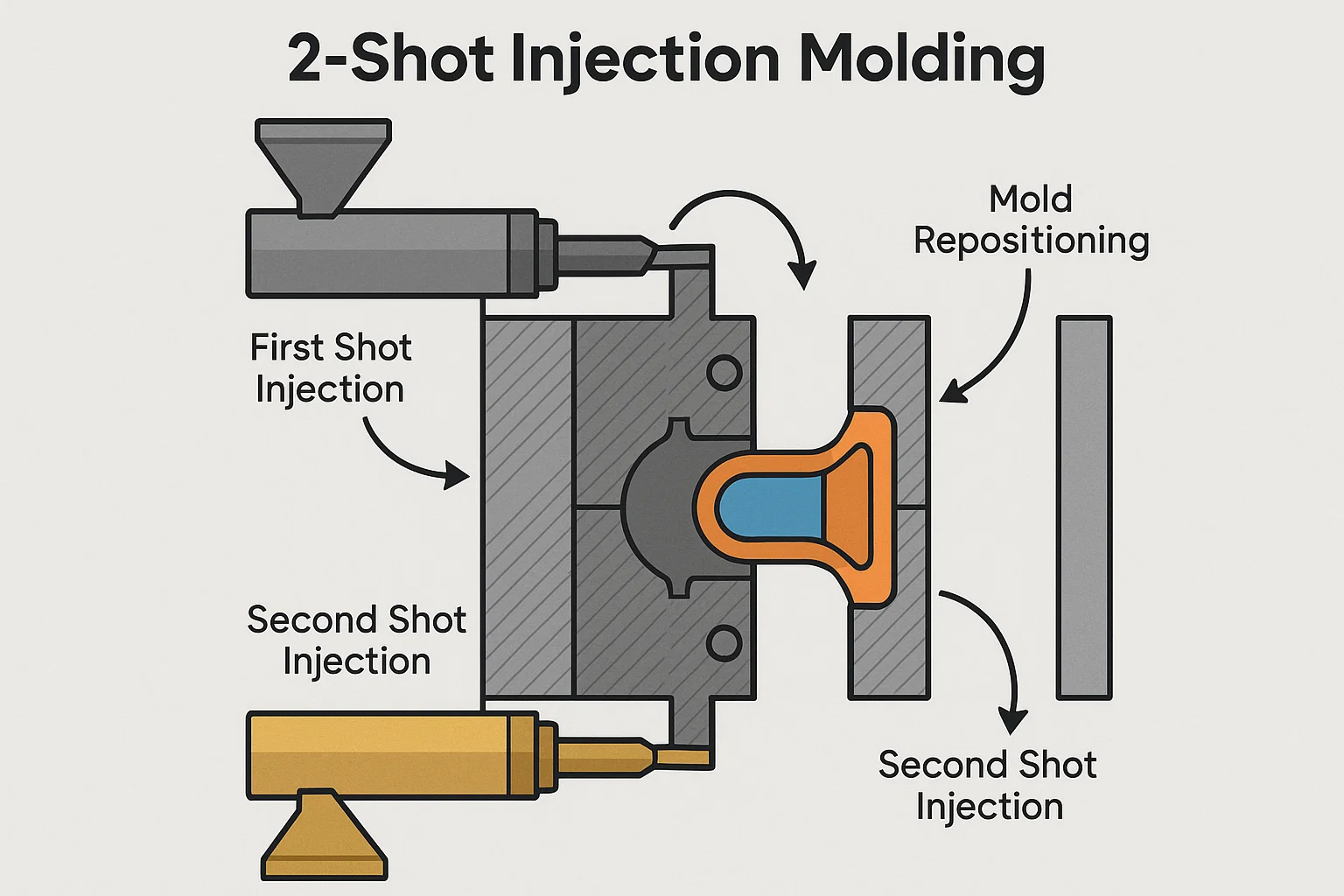

Basic Principle and Process Overview

The fundamental principle of 2-shot injection molding is the sequential injection of two materials into a specially designed mold. The process generally follows these key steps:

-

First Shot Injection: The first material (often a rigid plastic) is injected into the primary cavity of the mold.

-

Mold Repositioning: The mold then opens, and a platen or core rotates or transfers the newly formed first-shot part to a second cavity.

-

Second Shot Injection: The second material (often a softer plastic or different color) is injected into the new cavity, flowing around and bonding with the first-shot part.

-

Ejection: Once the second material has cooled and solidified, the finished, multi-material part is ejected from the mold.

This seamless integration of materials results in a high-quality, durable bond and a finished product that is ready for use, eliminating the labor and potential for error associated with traditional assembly.

History and Evolution

The origins of 2-shot molding trace back to the mid-20th century, driven by the need to create more sophisticated plastic products. Early methods were often crude and limited by the capabilities of both materials and machinery. The true evolution of the process began with the development of specialized injection molding machines featuring rotary platens and core-back technologies. These advancements, coupled with ongoing innovations in polymer science that introduced a wider range of compatible materials, have transformed 2-shot molding from a niche technique into a widely adopted, indispensable manufacturing solution for countless industries today.

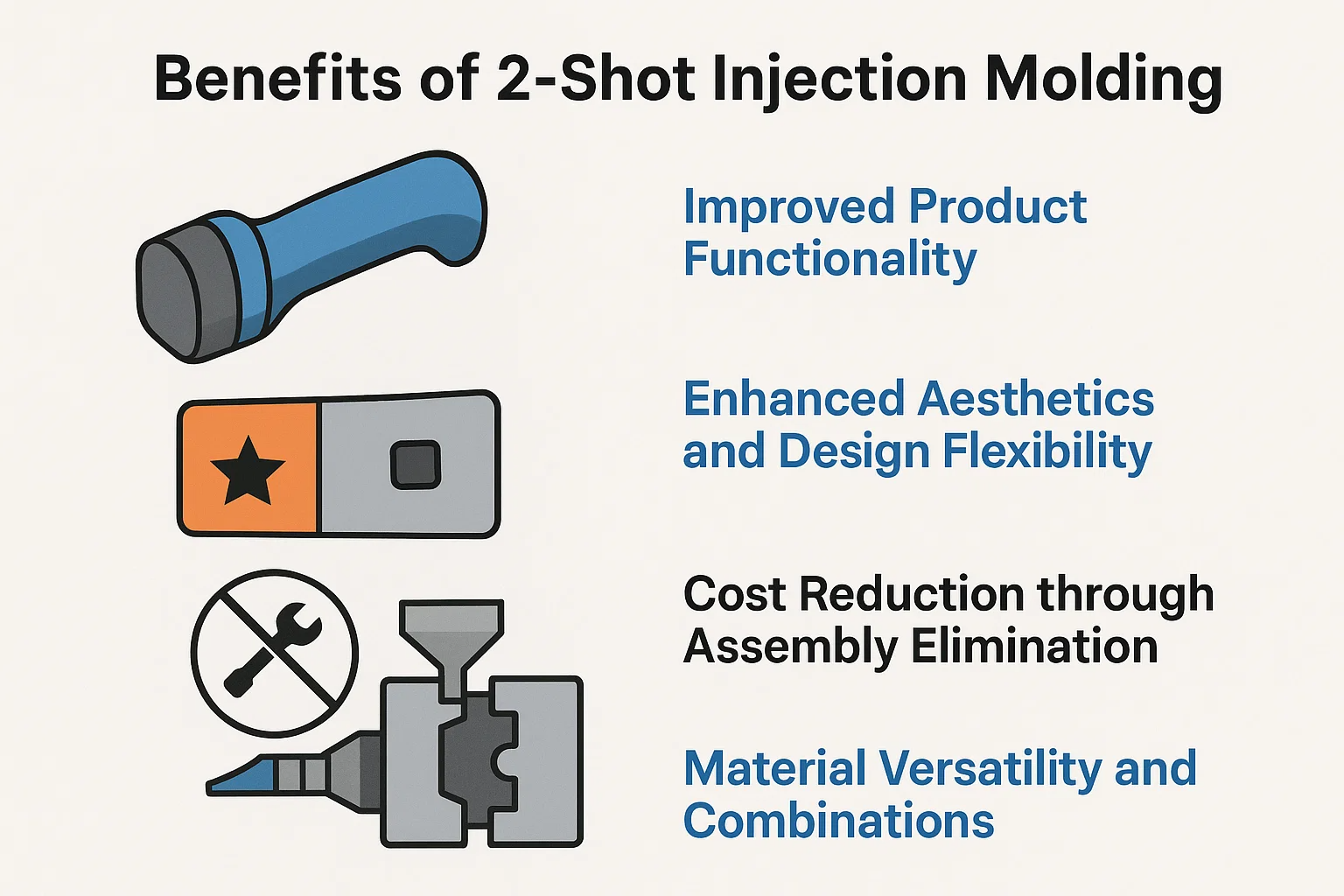

Benefits of 2-Shot Injection Molding

The strategic choice to employ 2-shot injection molding goes beyond mere technical sophistication; it delivers a host of tangible benefits that can dramatically impact a product's performance, cost-effectiveness, and market appeal. By integrating two separate manufacturing steps into a single, seamless process, 2-shot molding solves many of the challenges associated with multi-component products.

Improved Product Functionality

One of the most significant advantages of 2-shot molding is its ability to enhance a product's functionality by combining materials with different properties. For example, a rigid thermoplastic can form the structural body of a product, while a soft thermoplastic elastomer (TPE) is overmolded onto it to create a comfortable, non-slip grip. This technique is essential for power tools, consumer electronics, and medical instruments where ergonomics and tactile feel are critical. Furthermore, the process is ideal for creating integrated seals, gaskets, and living hinges, which improve a product's durability, waterproofing, and overall performance without the need for separate components that could fail over time.

Enhanced Aesthetics and Design Flexibility

2-shot molding provides unparalleled design flexibility, allowing engineers and designers to realize more complex and visually appealing products. By injecting two different-colored materials into the same mold, the process can create intricate logos, branding, or color-coded features that are permanently bonded to the part. This eliminates the need for painting, pad printing, or labeling, which can fade or chip. The ability to create different textures on a single surface—such as a smooth glossy finish next to a textured matte grip—also elevates the product's perceived quality and aesthetic value.

Cost Reduction through Assembly Elimination

Perhaps the most compelling business case for 2-shot molding is the substantial cost reduction achieved by eliminating secondary assembly. Traditional manufacturing of a two-material part would require molding two separate pieces and then manually or robotically joining them using adhesives, screws, or other fasteners. This multi-step process adds significant labor costs, requires additional equipment, and increases the risk of assembly errors. By producing a finished, multi-material part in a single molding cycle, 2-shot molding bypasses these expenses, leading to a leaner production line and lower per-unit costs.

Material Versatility and Combinations

2-shot molding opens up a vast world of material combinations, allowing engineers to select the ideal properties for each part of a component. The process is not limited to a rigid plastic and a soft grip; it can combine two different hard plastics, a clear plastic with an opaque one, or a thermoplastic with a thermoset material. This versatility allows for the creation of parts with a strong, rigid core and a durable, flexible exterior, or components with both electrical insulation and thermal conductivity properties. The key is selecting materials that are chemically and thermally compatible to ensure a strong, reliable bond.

Increased Production Efficiency

By consolidating multiple steps into a single process, 2-shot injection molding significantly increases overall production efficiency. The time-consuming and often labor-intensive steps of assembly, curing, or waiting for adhesives to dry are completely removed from the manufacturing flow. This results in a faster cycle time from raw material to a finished, salable product. The streamlined process requires fewer machines, less factory floor space, and a smaller workforce, all of which contribute to a more efficient and profitable manufacturing operation.

The 2-Shot Injection Molding Process

Understanding the intricate mechanics of 2-shot molding is key to appreciating its efficiency and precision. While the process may seem complex, it is a highly controlled sequence of events that results in a single, perfectly integrated part. Below is a detailed breakdown of the step-by-step process and the primary techniques used to achieve it.

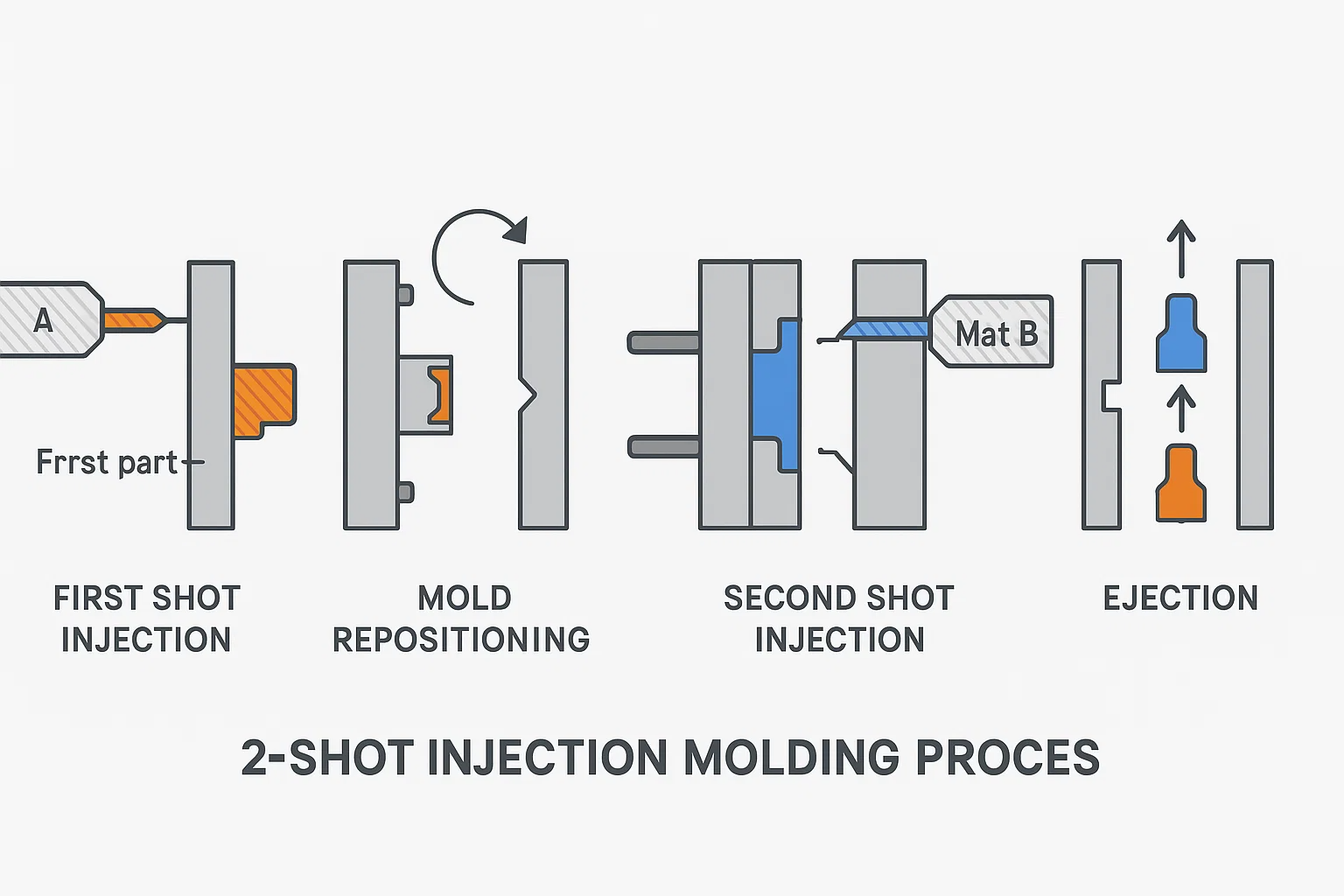

Detailed Step-by-Step Explanation

The journey of a 2-shot molded part begins with two separate injection units feeding different materials into a single, specialized mold. The process unfolds as a synchronized cycle:

-

First Shot Injection: The process begins with the injection of the first material, often a rigid thermoplastic (Material A), into the first mold cavity. This cavity forms the core or substrate of the final part. Once the material has been injected and a sufficient cooling time has passed, the first part is solidified.

-

Mold Repositioning: This is the most crucial phase of the cycle. The mold opens, and a precision mechanism repositions the first part. This is typically done in one of two ways: either the mold’s rotary platen turns 180 degrees, or a shuttle system transfers the part. The key is to move the first-shot component to the second, empty cavity, which is designed to receive it. Simultaneously, the first cavity is presented to the first injection unit again to start a new cycle.

-

Second Shot Injection: With the first-shot part now securely in the second cavity, the mold closes again. The second injection unit then injects the second material (Material B), often a different color, a softer elastomer, or another compatible polymer, into the space surrounding the first part. The new material bonds to the first part, either chemically or mechanically, creating the final, integrated component.

-

Ejection: After the second material has cooled and solidified, the mold opens for the final time. An ejection system, typically pins, pushes the finished, two-material part out of the mold. The cycle is complete, and the machine is ready to begin a new one.

Types of 2-Shot Molding Techniques

While the step-by-step process is fundamentally the same, manufacturers use different machine and mold configurations to achieve the desired outcome. The three most common techniques are:

-

Rotary Table Molding: This is the most prevalent and efficient method. The machine's platen is equipped with a rotating table that holds the mold. The first shot is made on one side of the mold. The platen then rotates, aligning the first-shot part with the second injection unit while a new first-shot part is simultaneously molded on the other side. This simultaneous production significantly reduces cycle time and is ideal for high-volume manufacturing.

-

Core Back Molding: This technique uses a sliding core or a movable insert within a single mold. After the first shot is injected, the core slides back to create the space for the second material. The second material is then injected into this newly formed cavity. This method is often used for parts with intricate details, such as integrated living hinges or very small components, where the mechanical complexity of a rotary table is not feasible.

-

Transfer Molding: In this method, the first-shot part is injected in one mold, and a robotic arm or mechanical transfer system physically moves the part to a separate, second mold on the same machine. This technique is less common for standard 2-shot applications but can be useful when the two molds require different clamping forces or if the two shots need to be made on separate machines.

Materials Used in 2-Shot Injection Molding

The success of any 2-shot injection molding project hinges on the careful selection of materials. The two polymers must not only meet the functional and aesthetic requirements of the final product but also be compatible with each other to form a strong, lasting bond. This section explores the types of material combinations and the critical criteria for selecting them.

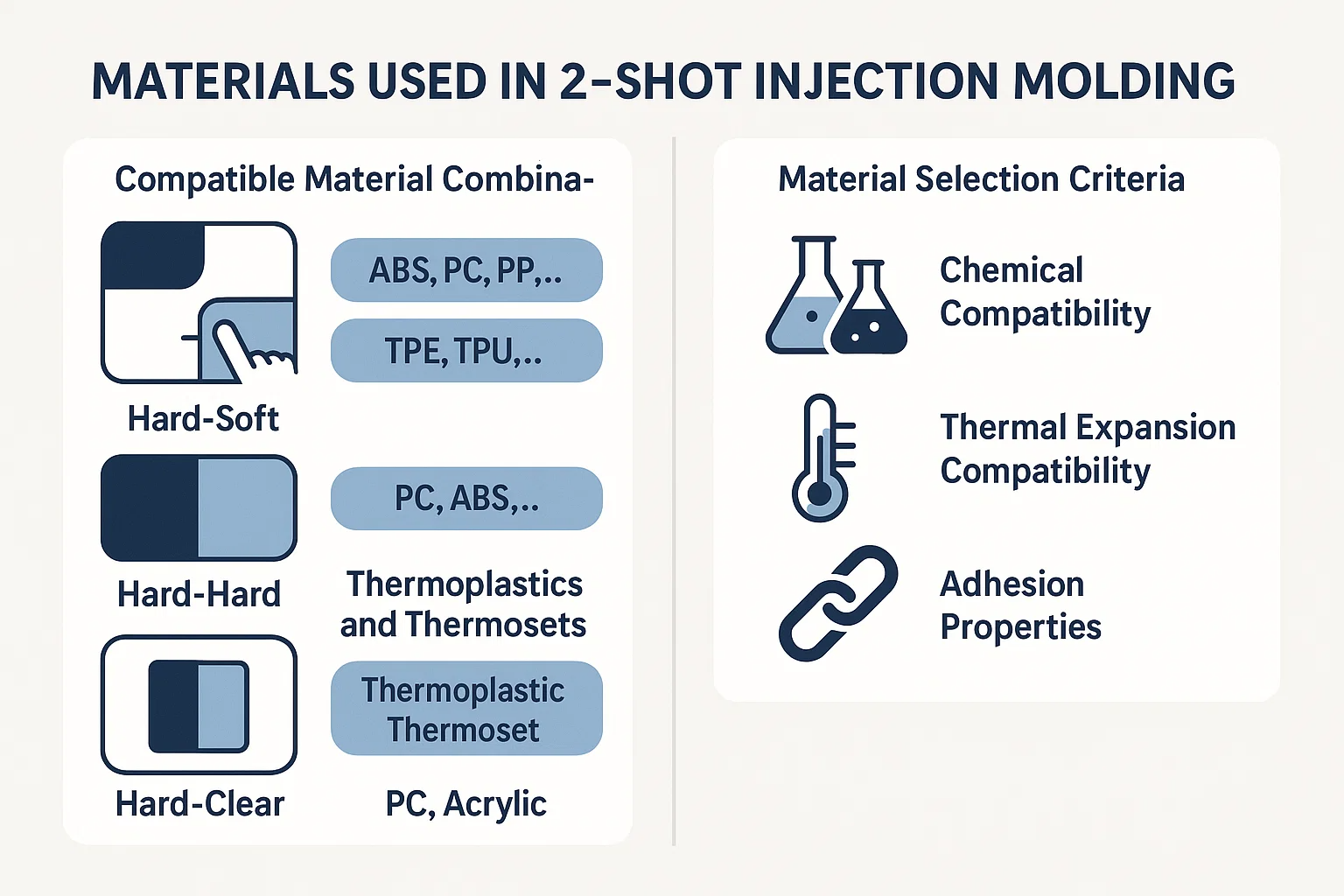

Compatible Material Combinations

The versatility of 2-shot molding is defined by the wide range of material pairings it can handle. These combinations are typically categorized based on the properties of the materials being used:

-

Hard-Soft Combinations: This is the most common application of 2-shot molding, where a rigid base material is combined with a soft, pliable material. The rigid material (e.g., ABS, Polycarbonate (PC), Nylon, Polypropylene (PP)) provides the structural integrity, while the soft material (e.g., Thermoplastic Elastomers (TPEs) or Thermoplastic Polyurethanes (TPUs)) provides an ergonomic grip, a waterproof seal, or a soft-touch surface. This is ideal for products like power tool handles, toothbrush grips, and medical instruments.

-

Hard-Hard Combinations: This combination involves two different rigid plastics. This might be done to combine specific properties, such as molding a strong Polycarbonate (PC) base with a more chemically resistant Acrylonitrile Butadiene Styrene (ABS) exterior. This is also used to combine two different colors of the same material for branding or aesthetic purposes, such as a black and a white piece of ABS for a control panel button.

-

Thermoplastics and Thermosets: While less common, certain specialized applications can involve pairing a thermoplastic with a thermoset or an elastomer. This is a complex process that requires careful control of temperature and pressure, as thermosets cure irreversibly upon heating.

-

Hard-Clear Combinations: This is used to create parts with integrated windows, light pipes, or display screens, such as a smartphone case with a clear port for the camera lens. Materials like Acrylic or Polycarbonate (PC) are often used for the clear component due to their optical clarity and durability.

Material Selection Criteria

Choosing the right materials for a 2-shot project involves a careful evaluation of several key properties. The success of the bond and the integrity of the final part depend on these factors:

-

Chemical Compatibility: This is the most critical factor. For a strong, permanent bond to form, the two polymers must be chemically compatible, allowing their molecules to form an adhesive interface. Polymers with similar chemical compositions or those that are in the same polymer family (e.g., PC and ABS) often bond well. Conversely, materials from different families (e.g., an amorphous polymer like PC and a crystalline polymer like PP) often have poor chemical adhesion, leading to delamination.

-

Thermal Expansion Compatibility: The two materials should have similar coefficients of thermal expansion and comparable shrinkage rates. As the finished part cools in the mold, each material will shrink. If their shrinkage rates are drastically different, it can cause internal stresses, leading to warping, cracking, or a weak bond at the interface. Careful material selection and mold design are essential to compensate for these differences.

-

Adhesion Properties: The bond between the two materials can be either chemical or mechanical. A chemical bond is a direct molecular connection formed at the interface. A mechanical bond is created when the second material flows into undercuts, ribs, or other features molded into the first part, creating a physical interlock. The best 2-shot designs often leverage both chemical and mechanical adhesion to ensure the strongest possible bond, even under stress. The material selection must take into account how well the two polymers will adhere under the specific processing conditions.

Mold Design Considerations for 2-Shot Molding

The success of a 2-shot injection molding project is intrinsically tied to the precision and complexity of its mold design. The mold is the central component of the process, and its engineering dictates the quality, integrity, and final aesthetics of the product. Designing a 2-shot mold is far more intricate than designing a single-shot mold, as it must function as two molds in one, accommodating two separate injection processes.

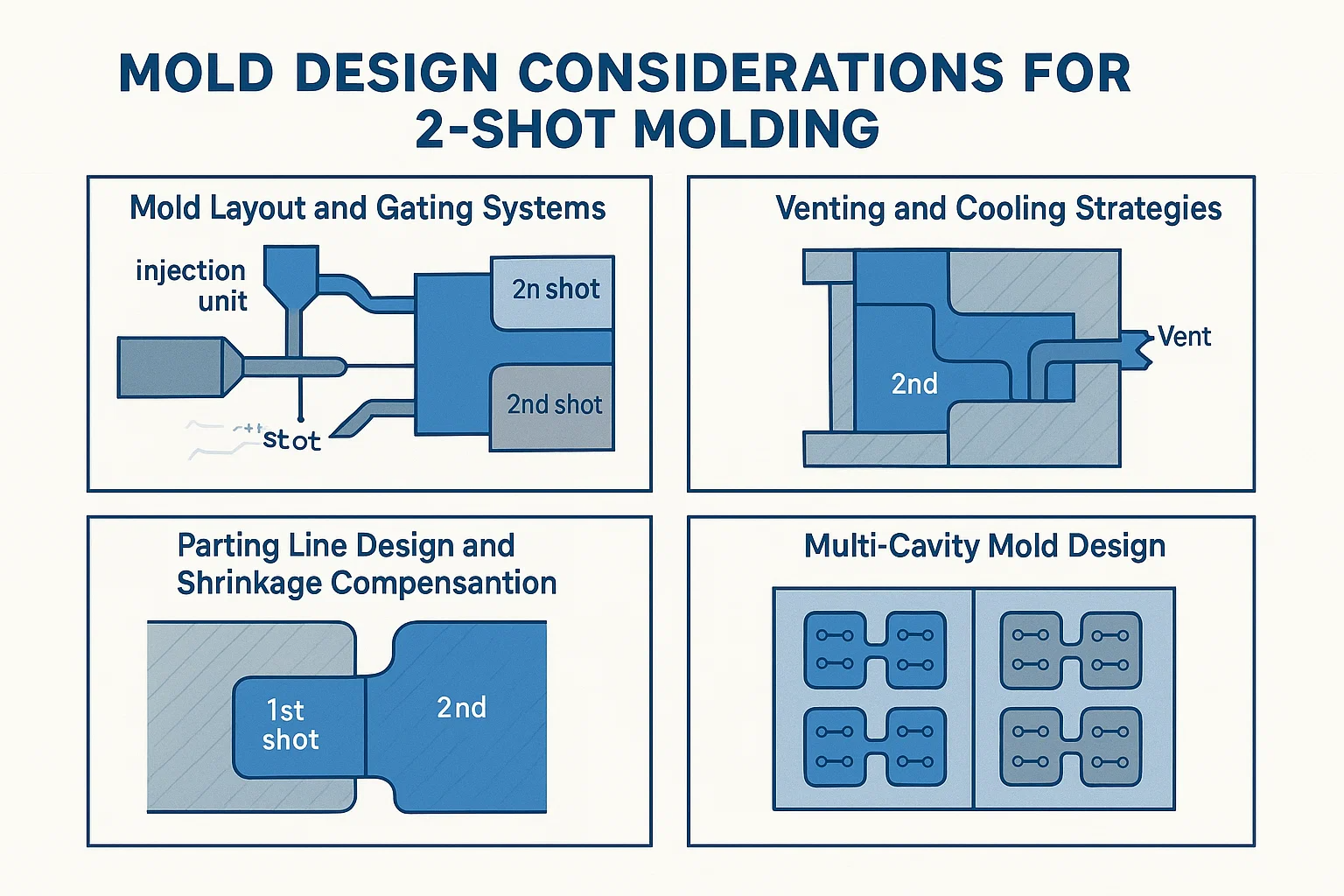

Mold Layout and Gating Systems

A 2-shot mold must be laid out to contain two distinct sets of cavities: one for the first shot and one for the second. The gating system—the channels that direct molten plastic into the cavities—is a critical part of this design. There are two separate gating systems, each feeding from its own injection unit. The design must ensure that each material is directed to its intended cavity without cross-contamination.

-

The first-shot gate directs the initial material into its cavity.

-

The second-shot gate is positioned to allow the second material to flow over or around the first-shot part. This gating system must be carefully placed to prevent damage to the pre-existing first shot and to ensure complete and uniform filling of the second-shot cavity.

Venting and Cooling Strategies

Effective venting is crucial in all injection molding, but it becomes even more critical in 2-shot molding. As the second material is injected around the first-shot part, air can easily become trapped in small pockets, leading to defects like burn marks, short shots, or incomplete bonds. The mold design must include strategically placed vents to allow this air to escape.

A well-designed cooling system is also essential for maintaining part quality and optimizing cycle time. In a 2-shot mold, the cooling channels must be designed to cool the first-shot part sufficiently before the second shot is injected. If the first part is too hot, the second shot can warp or melt it. Proper cooling ensures uniform temperature across the mold, which is vital for dimensional stability and preventing defects like warping.

Parting Line Design and Shrinkage Compensation

The parting line is where the two halves of the mold meet. For 2-shot molding, this line must be meticulously designed to ensure a tight seal at two different stages. The parting line for the second-shot cavity must seal against the first-shot part to prevent the second material from flowing into unwanted areas. This requires exceptional precision to avoid flashing (material leaking out of the mold).

Shrinkage compensation is another significant challenge. All plastics shrink as they cool, but the two different materials used in a 2-shot part will have different shrinkage rates. The mold designer must account for this differential shrinkage. If not properly compensated, the final part can experience warping, internal stress, or delamination, leading to a weak bond and a defective product.

Multi-Cavity Mold Design

For high-volume production, 2-shot molds can be designed with multiple cavities to produce several parts per cycle. This significantly increases efficiency but also adds a layer of complexity to the mold design. The runner systems for both shots must be meticulously balanced to ensure that all cavities are filled evenly and simultaneously. This prevents variations in part quality from one cavity to the next. While a multi-cavity 2-shot mold has a much higher initial cost, the long-term savings in production time and labor make it a cost-effective solution for mass manufacturing.

Applications of 2-Shot Injection Molding

The unique combination of functionality, aesthetics, and efficiency offered by 2-shot injection molding makes it a preferred manufacturing method across a wide spectrum of industries. Its ability to create a single, multi-material part in one cycle has solved complex design and assembly challenges, leading to enhanced product quality and performance in the following sectors.

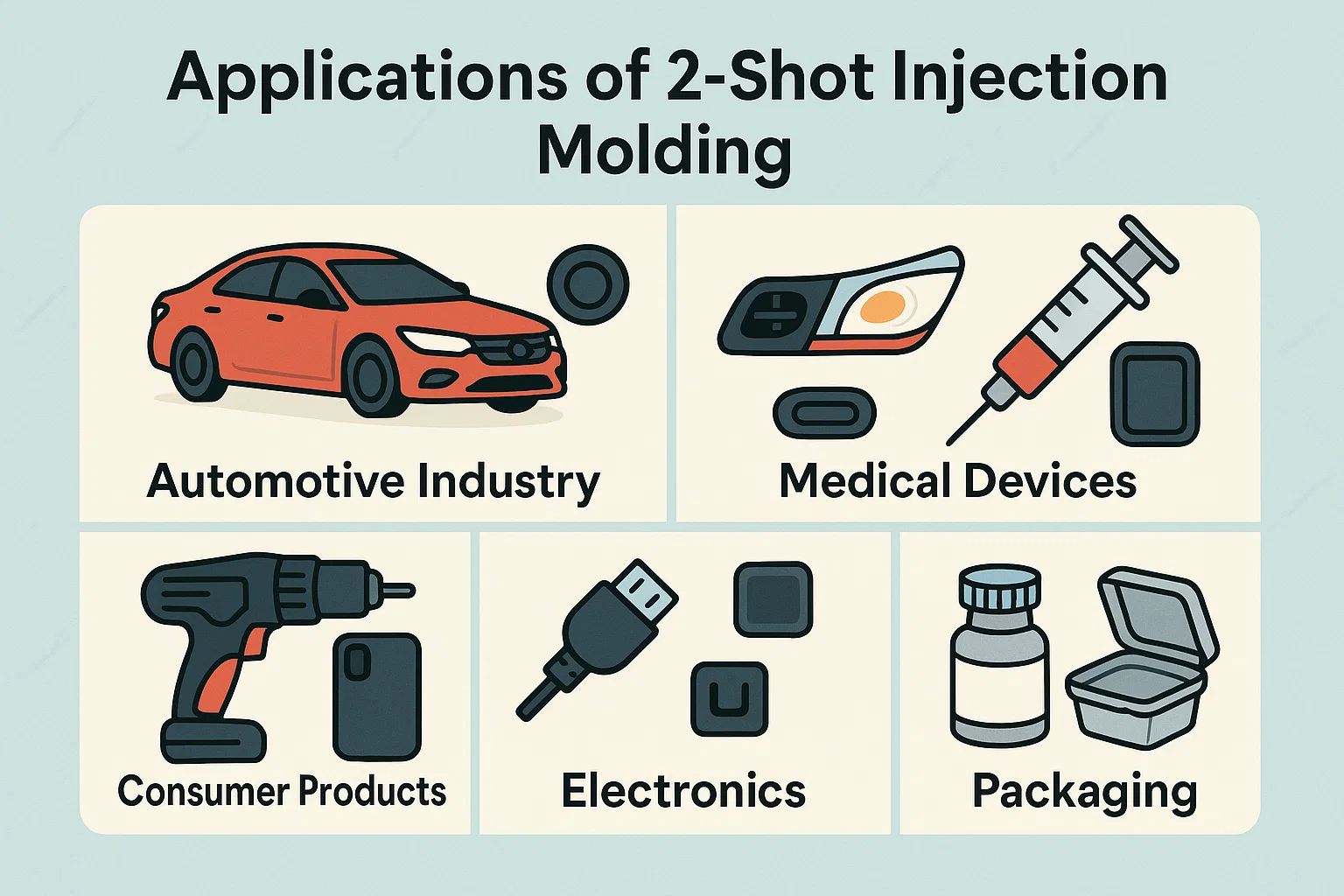

Automotive Industry

The automotive sector heavily relies on 2-shot molding for both interior and exterior components. It's used to create parts that are both durable and tactile.

-

Interior Components: It's common to find 2-shot molded parts in vehicle interiors, such as dashboard buttons, air vents, and gear shift knobs. A hard plastic provides the rigid structure and mounting points, while a soft-touch elastomer creates a premium feel and ergonomic grip, reducing noise and vibration.

-

Exterior Components: For exterior parts, 2-shot molding is used for headlight and taillight housings with integrated, water-tight seals. It is also used to create complex side mirror assemblies or intricate grille designs that combine two different colors or finishes.

Medical Devices

In the medical field, precision, hygiene, and reliability are paramount. 2-shot molding is essential for producing high-quality, sterile, and functional devices.

-

Surgical Instruments: The handles of many surgical tools and instruments are 2-shot molded. A rigid polymer provides a strong, autoclavable core, while a soft-touch, ergonomic grip improves a surgeon's control and reduces hand fatigue.

-

Drug Delivery Systems: Syringes, inhalers, and other drug delivery devices often use 2-shot molding to create integrated seals and gaskets, ensuring the contents remain sterile and that the device functions correctly without leaks.

Consumer Products

From household gadgets to personal electronics, 2-shot molding enhances the user experience through improved ergonomics and durability.

-

Power Tools: This is a classic application. Power tool handles feature a rigid structural body, typically made of nylon or PC, overmolded with a TPE or TPU grip. This provides a comfortable, non-slip surface that's resistant to impact and chemicals.

-

Mobile Phone Cases: Many high-end phone cases are 2-shot molded, combining a rigid polycarbonate skeleton for structural protection with a shock-absorbent TPU bumper to guard against drops.

Electronics

Electronics require precision parts, often with integrated sealing or complex tactile features.

-

Connectors: 2-shot molding is used to create sealed connectors and integrated strain relief on cables, making them waterproof and more durable.

-

Buttons: It's a key process for making remote control buttons and keyboard keys. A rigid inner core provides a solid feel, while a soft or clear material is used for the top surface, allowing for tactile feel or backlighting.

Packaging

In the packaging industry, 2-shot molding is used to create functional and appealing containers and closures.

-

Closures: Many bottle caps and closures are 2-shot molded with an integrated seal. A hard plastic forms the cap, while a soft-touch elastomer on the inside creates an airtight seal without the need for a separate gasket or liner.

-

Containers: It is used for specialized containers that require both a rigid structure and a flexible, snap-on lid or seal.

Advantages and Disadvantages of 2-Shot Injection Molding

Like any advanced manufacturing technique, 2-shot injection molding offers a unique set of benefits and drawbacks. A clear understanding of these trade-offs is essential for determining if the process is the right fit for a specific product.

Advantages

-

Reduced Assembly Costs: One of the biggest advantages is the elimination of secondary assembly. By producing a finished, multi-material part in a single molding cycle, the process removes the need for manual labor, adhesives, screws, or other fasteners, leading to significant cost and time savings.

-

Improved Product Quality: The integrated nature of 2-shot molding results in a superior product. The molecular or mechanical bond created between the two materials is stronger and more durable than a conventional assembled joint, eliminating the risk of parts becoming loose or rattling over time.

-

Enhanced Design Possibilities: The process allows for creative and complex designs that are not feasible with single-shot molding. Designers can combine different colors, textures, and material properties (e.g., a rigid structural body with a soft-touch, ergonomic grip) into a single, seamless component.

-

Better Grip and Ergonomics: For consumer, medical, and industrial products, the ability to overmold a soft, tactile elastomer onto a hard plastic surface is a key benefit. This improves the user's grip, enhances comfort, and can provide a level of safety not achievable with a single material.

Disadvantages

-

Higher Initial Mold Cost: The most significant disadvantage is the high upfront cost of the mold. A 2-shot mold is far more complex than a standard mold, featuring dual cavities, a rotating platen or core back mechanism, and intricate cooling and gating systems, all of which substantially increase its design and manufacturing expenses.

-

Complex Mold Design: The design and engineering of a 2-shot mold require specialized expertise. It's a challenging process that must account for the unique properties of two different materials, including their shrinkage rates, chemical compatibility, and processing temperatures. This complexity can extend the design and prototyping phases.

-

Longer Cycle Times (potentially): While more efficient than separate molding and assembly, the cycle time for a 2-shot part can be slightly longer than a single-shot part. The machine must complete two separate injection and cooling phases, which can add to the overall production time, especially for less complex parts.

-

Material Compatibility Challenges: The designer's choice of materials is limited to combinations that are chemically and thermally compatible. Not all polymers can form a strong bond, and using incompatible materials can lead to delamination, warping, and a weakened product.

Cost Analysis of 2-Shot Injection Molding

The decision to use 2-shot injection molding is often a strategic one, balancing a higher initial investment against significant long-term savings and product benefits. A thorough cost analysis must consider all stages of production, not just the initial tooling.

Factors Affecting Cost

-

Mold Complexity: The most significant factor driving the cost of 2-shot molding is the mold itself. A 2-shot mold is a highly complex piece of engineering, featuring two sets of cavities, a rotating platen or shuttle system, and intricate cooling and gating channels. This requires specialized design expertise and precision machining, making the initial mold cost substantially higher than that of a conventional single-shot mold.

-

Material Costs: Using two different materials can impact overall costs, especially if one is a premium thermoplastic elastomer (TPE) for a soft-touch grip or a high-performance engineering polymer. The cost per pound of these materials can be higher than that of a standard single-shot resin.

-

Production Volume: 2-shot molding is a process designed for high-volume manufacturing. The high upfront tooling cost is most efficiently amortized over hundreds of thousands or even millions of parts. For low-volume production, the per-part cost remains prohibitively high, making traditional molding and assembly a more cost-effective choice.

-

Cycle Time: While a 2-shot cycle is longer than a single-shot cycle, its efficiency lies in producing a finished product in one go. The cycle time is a critical factor in determining the cost per part, as it dictates the machine's throughput. A well-designed 2-shot mold with a balanced cycle time can be far more cost-effective than a multi-step assembly process.

Cost-Benefit Analysis: When to Choose 2-Shot Molding

The decision to opt for 2-shot molding should be based on a total cost of ownership calculation. You should choose 2-shot molding when the savings from eliminating secondary assembly outweigh the higher upfront tooling cost.

Consider 2-shot molding when your product:

-

Requires complex assembly: If your product would otherwise need to be manually glued, screwed, or sealed after molding, the labor and material costs of assembly will likely justify the 2-shot process.

-

Demands superior quality and aesthetics: For products where a perfectly integrated bond, an ergonomic grip, or a two-color aesthetic is critical to brand identity and customer satisfaction, 2-shot molding is the ideal choice.

-

Is a high-volume product: As a rule of thumb, if production volumes are high enough, the cost of the mold can be spread across a massive number of units, making the per-part cost significantly lower than an assembled alternative.

The initial expense is a barrier, but for the right application, the long-term cost reductions, coupled with a higher-quality product, make 2-shot molding an excellent investment.

Quality Control in 2-Shot Injection Molding

Given the complexity of 2-shot injection molding, rigorous quality control is essential to ensure that the final product meets both functional and aesthetic specifications. Monitoring and preventing common defects is a key part of the process.

Common Defects and How to Prevent Them

-

Delamination: This is the separation of the two materials at their interface. It's often caused by insufficient chemical or thermal compatibility, or by incorrect process parameters like low melt temperature or inadequate pressure. Prevention involves selecting compatible materials, optimizing injection temperatures, and ensuring the second shot's melt is hot enough to create a strong bond with the first shot's surface.

-

Warping: A deformation or twisting of the part, typically caused by uneven cooling or a significant difference in the shrinkage rates of the two materials. To prevent warping, designers must choose materials with similar thermal properties and ensure the mold's cooling system is balanced to cool all sections of the part uniformly.

-

Sink Marks: These are small depressions on the surface of the part. In 2-shot molding, they often occur in areas where the second material is thick and shrinks as it cools, pulling on the first material. They can be prevented by increasing packing pressure, extending the hold time, and carefully designing the part to avoid large, thick sections.

-

Weak Bond: This is a general term for a bond that fails under stress. It can be caused by contamination on the first-shot part's surface (e.g., from mold release agents), improper melt temperatures, or insufficient time for the second material to fuse with the first. Prevention involves maintaining a clean production environment, ensuring optimal process parameters, and sometimes even using destructive testing to verify bond strength.

Inspection Techniques and Equipment

-

Visual Inspection: As the first line of defense, trained technicians visually inspect each part for cosmetic defects. This includes checking for color variations, sink marks, flash (excess material), or any signs of delamination.

-

CMM (Coordinate Measuring Machine): For dimensional accuracy, a CMM is used. This precision machine uses a probe to take highly accurate measurements of a part's geometry, ensuring that all features are within the specified tolerances. This is especially important for 2-shot parts where two materials must integrate perfectly.

-

Destructive Testing: To directly verify the bond strength between the two materials, a small sample of parts is subjected to destructive tests. This can involve pulling the two materials apart in a tensile test, twisting the part, or an impact test. This method confirms that the bond is strong enough to meet the product's performance and durability requirements.

Future Trends in 2-Shot Injection Molding

The 2-shot injection molding industry is in a constant state of evolution, driven by technological advancements and a growing demand for more complex, efficient, and sustainable manufacturing. The future of the process will be shaped by several key trends that promise to enhance its capabilities and intelligence.

Advancements in Materials

The development of new polymers is a critical trend. Manufacturers and material scientists are focusing on creating specialized materials that offer enhanced properties and new functionalities. This includes bio-based and recycled polymers to address sustainability concerns, as well as new elastomers and engineering plastics with superior characteristics. These materials will offer stronger chemical bonds, higher temperature resistance, and more precise tactile (haptic) feedback, further expanding the applications of 2-shot molding.

Automation and Robotics

Automation is already integral to 2-shot molding, but it's becoming more sophisticated. The next wave of innovation will see robots and collaborative robots (cobots) performing more intricate tasks beyond simple part removal. This includes in-mold assembly of inserts, automated quality checks, and complex part handling. This increased automation will reduce labor costs, improve production consistency, and allow for lights-out manufacturing, where machines can operate without human supervision.

Simulation and Optimization Software

The use of advanced software is revolutionizing the mold design process. Engineers now use powerful simulation software to model the entire 2-shot molding cycle. This allows them to predict and prevent common defects like warping, weak bonds, or uneven filling before the mold is manufactured. By optimizing mold designs and process parameters virtually, manufacturers can significantly reduce the need for costly physical prototypes, leading to faster product development cycles and a higher first-time success rate.

Industry 4.0 Integration

The integration of 2-shot molding into the smart factory ecosystem (Industry 4.0) is a major trend. Machines are being equipped with sensors that collect real-time data on temperature, pressure, and other critical process variables. This data is then fed into a central system for analysis, allowing for predictive maintenance, optimized energy usage, and automated process adjustments. This level of connectivity and data analysis enables a shift from reactive to proactive manufacturing, ensuring consistent product quality and maximum operational efficiency.

English

English bahasa Indonesia

bahasa Indonesia