Injection molding helps make many things you use. It is used for cars and toys. It is also used in many industries. These include automotive, aerospace, and medical devices. It is used for consumer products and telecommunications. You see it in construction and food packaging. It helps make defense equipment and electronics. It is also used for recreation. The process uses melted materials. These materials are pushed into molds. This makes strong and exact parts very quickly. Here are some main benefits:

|

Benefit |

Description |

|---|---|

|

Production Speed |

Makes thousands of parts each day. It is much faster than other ways. |

|

Cost-Effectiveness |

Lowers cost per part for big jobs. This helps you save money. |

|

Versatility in Design |

Handles hard shapes and many materials. This helps with different needs. |

|

Environmental Benefits |

Makes less waste and helps recycling. This is better for the planet. |

You see this in things like medical syringes. It is also used for phone cases and food containers.

Key Takeaways

-

Injection molding is a quick and cheap way to make plastic parts for many businesses. It helps make strong and exact pieces for cars, planes, hospitals, and things people use every day. The process uses less material, so it is better for the environment than old ways. Injection molding lets companies make many different shapes and details. Medical devices made this way are safe, exact, and very clean. Things like toys, kitchen tools, and packages are often made with injection molding, so they are good and safe. The telecommunications field uses injection molding to make strong and light covers for devices. In the future, injection molding will use more earth-friendly materials and more machines to work faster.

Automotive Injection Molding

Car makers use injection molding to make many car parts. This process shapes both the inside and outside of cars, trucks, and SUVs. You get parts that are strong, light, and not expensive. These parts help keep cars safe and comfy.

Interior Parts

Dashboard Panels

You touch dashboard panels every time you drive. Injection molding helps make these panels with smooth shapes. Dashboards fit well and last a long time. Designers can add things like air vents and screens into the panel. Thermoplastics and elastomers keep dashboards strong but not heavy.

Door Handles

Door handles need to be strong and easy to hold. Injection molding makes handles that match the car’s look and color. These handles last for years because the materials are tough and bendy. Making many handles fast keeps prices low for everyone.

Exterior Parts

Bumpers

Bumpers help protect your car in small crashes. Injection molding shapes bumpers from materials that take hits and do not break easily. Bumpers look nice and work well. The process makes lots of bumpers, so all are safe.

Grilles

Grilles give cars their special look and help cool the engine. Injection molding lets makers design grilles with cool patterns and strong frames. Grilles fit well and last in all weather.

Note: Injection molding helps car makers save money and waste less. Parts come out close to the right shape, so there is less scrap than with cutting.

Here is how injection molding helps save money in car making:

|

Advantage |

Description |

|---|---|

|

Less Material Waste |

Parts are almost the right shape, so little is wasted. |

|

Low Production Costs |

After the mold is made, more parts are fast and cheap to make. |

|

High-Volume Output |

Factories can make thousands of parts each day for less money. |

You see these good things in every car. Fast production means new cars come out sooner. The process lets car makers use cheap materials that keep cars light and strong. Injection molding gives you cars that are safe, cool, and not too costly.

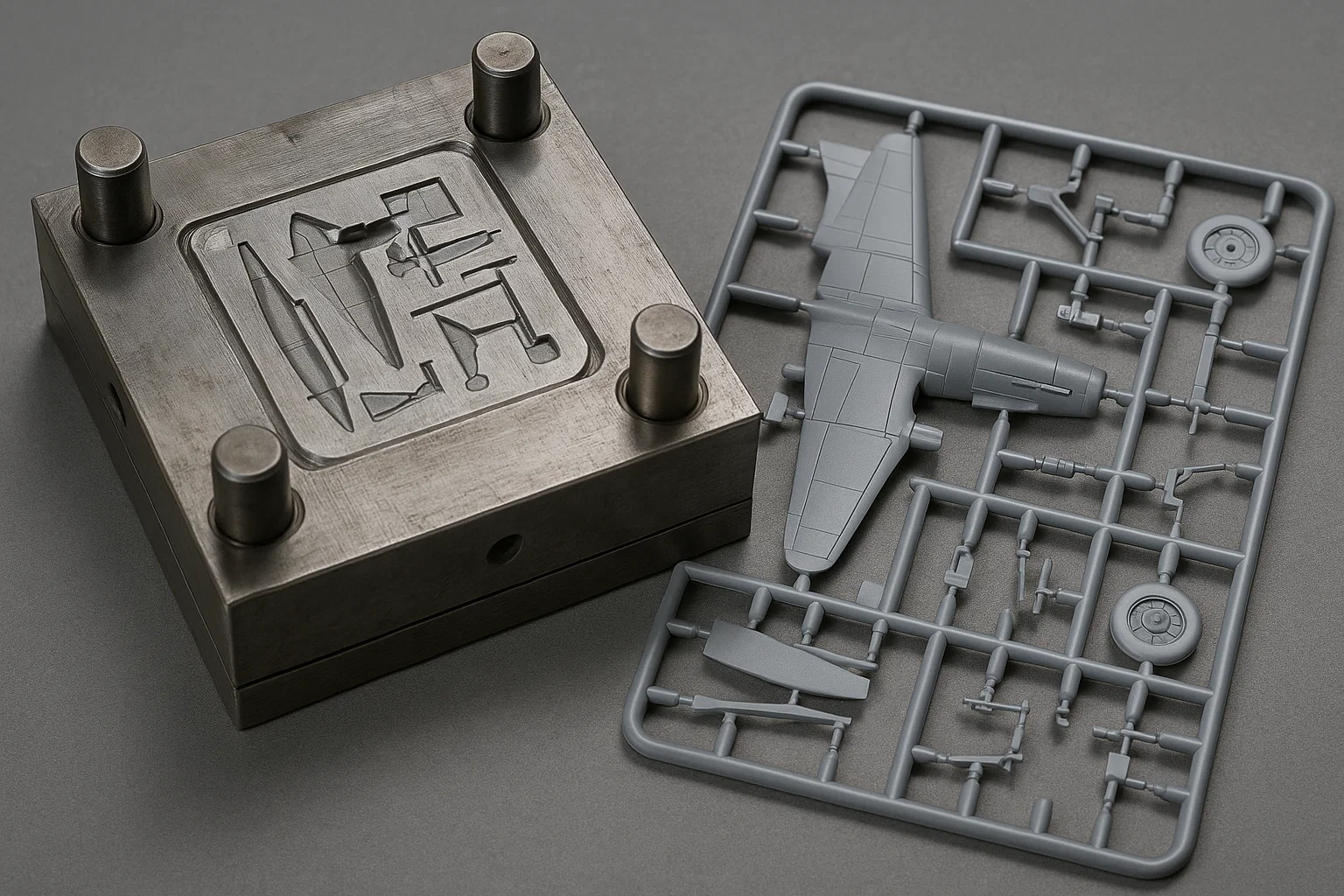

Aerospace Components

Aerospace engineers use new ways to make safe airplanes. Many airplane parts are made with injection molding. This process makes parts that are strong and light. Airplanes need parts that can handle lots of stress and heat. They also need to be light so planes use less fuel.

Jet Turbine Blades

Jet turbine blades face a lot of heat and force. These blades spin very fast inside engines. Engineers pick special plastics and composites for these blades. These materials do not melt or wear out fast. Injection molding shapes blades with curves and hollow spots. These shapes help make blades lighter and move air better. Ribbing and hollow parts save material but keep blades strong. This helps planes use less fuel and fly longer.

Injection-compression molding makes blades smooth and even. This keeps blades strong and the same size. Engines need this to work safely. Many companies use PEEK for these blades. PEEK does not break from heat or stress. It is great for engine parts.

Tip: Lighter blades help planes use less fuel and work better.

Flight Deck Parts

Pilots sit in the flight deck to fly the plane. Many parts here are made with injection molding. These include instrument covers, switches, and trim panels. These parts must be tough and not catch fire. Engineers use Ultem and polycarbonate-ABS blends for these parts. These plastics keep parts safe and light.

Injection molding lets you turn many metal parts into one plastic part. This means fewer screws and faster building. The parts fit well and last a long time. Smooth and even parts are important for pilot controls. Injection molding gives you these good features.

Here are some airplane parts made with injection molding:

-

Inside cabin: Light covers, trim panels, seat parts

-

Electronic covers: Used for controls and radios

-

Support pieces: Brackets and boxes that do not hold weight

-

Ducts and tubes: Light pipes for air and liquids

You find these parts in every new airplane. This process helps meet safety rules and saves money. Airlines trust injection molding for good and safe parts.

|

Material |

Benefit |

Common Use |

|---|---|---|

|

PEEK |

Handles heat and is strong |

Avionics covers |

|

Ultem (PEI) |

Light and does not burn easily |

Cabin parts |

|

Polycarbonate-ABS |

Tough and not costly |

Non-structural parts |

Injection molding helps the aerospace industry by making light and strong parts. These parts help planes fly safely and use less fuel.

Medical Devices Injection Molding

Medical devices are found in hospitals and clinics. Many are made using injection molding. This process shapes plastic into exact forms. The parts are strong, safe, and clean for patient care.

Prosthetics

Prosthetics help people move and live better. These parts need to fit well and last long. Injection molding makes custom shapes for arms, legs, and joints. The process uses biocompatible plastics. These plastics do not hurt the body. Lightweight parts feel comfortable for users. Many sockets and joints are made this way. Smooth finishes help stop skin irritation.

Tip: Custom prosthetics make patients more comfortable and help them move.

Equipment Housings

Medical machines need tough covers to protect inside parts. Injection molding makes strong housings for lab tools and monitors. These covers can handle cleaning and sterilization. You can pick plastics that resist heat and chemicals. The process makes parts with tight fits and smooth edges. This keeps dust and germs out. Dental X-ray equipment and drug delivery machines use these housings too.

Here are some items made with this process:

-

Covers for medical and lab equipment

-

Imaging parts

-

Patient care devices

-

Instrument covers

Disposable Products

Hospitals use many single-use items to keep patients safe. Injection molding makes these products fast and in large amounts. You get syringes, pipettes, petri dishes, and test tubes. These items must stay clean and germ-free. The process happens in cleanrooms to stop contamination. Catheter locks, testing kit parts, and protection equipment are made this way too.

Common disposable medical products:

-

Syringes

-

Pipettes

-

Petri dishes

-

Catheter locks

-

Diagnostic disposables

Strict rules must be followed when making medical devices. The FDA and ISO set safety and cleanliness standards. Cleanrooms, like ISO Class 7 or 8, keep parts sterile. Materials must survive cleaning and not hurt the body. Factories use good practices to make sure every part is safe.

|

Requirement |

Why It Matters |

|---|---|

|

FDA and ISO compliance |

Makes sure products are safe and high quality |

|

Biocompatible materials |

Safe for use in the body |

|

Cleanroom manufacturing |

Lowers risk of contamination |

|

Sterilization resistance |

Keeps products safe after cleaning |

Doctors and nurses trust injection molding for medical devices. It gives them precise, safe, and fast parts. This helps them care for patients with confidence.

Consumer Products

You use products made with injection molding every day. This process shapes many items you find at home, at school, or at work. Companies choose this method because it makes strong, colorful, and affordable products. The global market for these products reached US$ 295 billion in 2024. Experts expect it to grow to US$ 451.83 billion by 2033, with a steady increase of 5% each year. This growth shows how much you rely on these products in your daily life.

Everyday Items

You pick up many everyday items without thinking about how they are made. Toothbrushes, combs, and water bottles all come from molds. Makers use this process to create smooth shapes and bright colors. You get products that last and look good. The process allows companies to make thousands of items quickly, so you always find what you need in stores.

Did you know? Most toys, phone cases, and kitchen tools are made using this method. You benefit from safe, sturdy, and fun designs.

Here are some product categories that depend on this process:

|

Product Category |

Description |

|---|---|

|

Automotive Parts |

Used for durable and precise vehicle components. |

|

Toys |

Allows for colorful and detailed toys that meet safety rules. |

|

Consumer Electronics |

Makes sleek cases for phones and controllers. |

|

Household Goods |

Produces utensils and furniture in many styles. |

|

Packaging Products |

Creates containers and lids that keep food safe. |

|

Construction Components |

Makes pipes and fittings that last. |

You see these items in your home, school, and playground. The process helps keep prices low and quality high.

Household Goods

You use household goods every day. Kitchen utensils, storage bins, and chairs all come from this process. Makers design products in many shapes and colors. You find forks, spoons, and spatulas that do not break easily. Plastic furniture is light and easy to move. Storage bins help you organize your space. The process lets companies make these goods in large numbers, so you always have choices.

You also see this process in bathroom items like soap dishes and shower caddies. Makers use safe plastics that resist water and stains. You get products that last and stay clean. The process helps companies create new designs quickly, so you see fresh styles each year.

Tip: When you buy household goods, look for items that feel sturdy and have smooth edges. These are signs of good quality.

You depend on these products every day. The process helps companies meet your needs for safety, style, and value.

Telecommunications Injection Molding

Telecommunications help you talk to people far away. You use things like routers, modems, and smartphones all the time. These devices need to be tough and light. They also need to work well every day. Injection molding helps companies make these parts fast. It also helps keep costs low. You get devices that last longer and work better.

Device Housings

Device housings cover and protect the inside parts. You see these covers on routers and modems. Companies use injection molding to make smooth and strong shells. These shells keep out dust and water. Your devices look nice and feel sturdy.

Engineers can design housings with cool shapes and features. You see vents, slots, and buttons that fit just right. Makers pick plastics that do not melt or scratch easily. Polycarbonate is a favorite because it stays clear and strong. You find it in many device housings.

Here is how injection molding helps make better device housings:

|

Aspect |

Description |

|---|---|

|

Cost-Effective Production |

Makes lots of housings for less money. |

|

Design Flexibility |

Lets engineers create special shapes and features. |

|

Durability and Strength |

Makes housings tough and long-lasting. |

|

Lightweight Construction |

Keeps devices light and easy to carry. |

Reports say the market for plastics in telecommunications is growing. Experts think more people will buy smart devices and faster networks. You see new designs and lighter products every year.

Tip: Lighter housings make your devices easier to carry and set up.

Connectors

Connectors join cables and parts inside your devices. You use connectors when you plug in your internet or charge your phone. These parts need to be strong and fit well. Injection molding helps companies make connectors with exact shapes.

ABS plastic is a top pick for connectors. It is tough and easy to shape. You find ABS in many plugs and sockets. Some connectors need to be even stronger. Makers use PEEK for these because it does not break under pressure.

You see these materials in telecommunications parts:

-

Polycarbonate (PC): Used for housings in routers and modems because it is strong and clear.

-

Acrylonitrile Butadiene Styrene (ABS): Used for connectors because it is tough and easy to mold.

-

Polyether Ether Ketone (PEEK): Used for antenna parts because it is very strong.

Studies show that good connectors help stop signal loss. You get faster internet and clearer calls. Companies use injection molding to make millions of connectors that work well.

Note: When you buy a new device, check the connectors and housing. Good parts help your device last longer and work better.

Telecommunications need strong and light parts. Injection molding helps make products that keep you connected every day.

Construction Materials

Injection molding makes many plastic parts for buildings. You see these parts in plumbing and electrical systems. Some are even inside walls. This process gives you strong and safe materials. These materials do not cost a lot. Builders like injection-molded plastics. They last longer than metal or wood. They also cost less.

Pipe Connectors

Pipe connectors join pipes in plumbing and heating. You find them in homes, schools, and offices. Injection molding makes connectors in many shapes and sizes. These parts fit tight and do not leak. They do not rust, so water does not damage them.

You get many good things from plastic pipe connectors:

-

Plastic connectors cost less than metal ones.

-

They do not rust, so you fix them less often.

-

They work with hot and cold water and do not break.

Tip: Builders pick plastic connectors because they last longer and need less fixing.

A report says the plastic pipe market will be over $50 billion by 2030. More people want strong and cheap plumbing parts. Injection molding helps by making millions of connectors each year.

Electrical Boxes

Electrical boxes keep wires and switches safe. You see them behind light switches and outlets. Injection molding makes boxes that are strong and light. These boxes do not crack or melt when wires get hot. They also resist water and chemicals. This helps them work well in kitchens and bathrooms.

Here is how plastic boxes help you in buildings:

-

You pay less for materials and repairs.

-

The parts last long and resist moisture and sunlight.

-

You get designs for many building needs.

|

Feature |

Benefit for You |

|---|---|

|

Lightweight |

Easy to put in and move |

|

Non-conductive |

Safer for electrical jobs |

|

Custom shapes |

Fit any wall or ceiling space |

Note: Builders trust plastic boxes because they are safe and last for years.

You see more plastic parts in new buildings every year. Injection molding lets you get boxes with special features. Some have extra holes or built-in clamps. This helps you finish projects faster and safer.

Injection molding gives you strong and safe building materials. These parts last longer and help keep your building in good shape.

Food Packaging

You see food packaging in many places. Grocery stores use containers and bottle caps. Restaurants and homes use them too. Injection molding helps companies make packaging fast. This packaging keeps your food safe and fresh. You get strong, light, and clean packaging every day.

Containers

Food containers come in lots of shapes and sizes. You use them for leftovers and lunches. You also buy snacks in these containers. Companies pick injection molding because it is quick. It makes containers with exact shapes. You get containers that seal tight and do not leak. Most containers use food-grade plastics like polypropylene and polyethylene. These plastics keep your food safe. They do not change how your food tastes.

Industry reports say the food packaging market was over $350 billion in 2023. Experts think it will keep growing. More people want safe and easy packaging. You see new designs every year. Some containers stack up. Some are safe for microwaves.

Safety is important when you use food containers. Makers must follow strict rules to keep you healthy. Here are some standards they follow:

-

FDA Compliance: Materials must meet CFR Title 21 rules.

-

Good Manufacturing Practices (GMP): Factories keep products clean and safe.

-

European Food Safety Authority (EFSA): Rules protect you from harm.

-

National Sanitation Foundation (NSF) Standards: Extra checks for safety.

-

Material Certifications: Containers pass FDA and EU 10/2011 tests.

-

NSF and ISO 22000 Certifications: These show high safety standards.

-

Food-Grade Plastics: Only safe plastics touch your food. Unsafe plastics can cause health problems.

Tip: Always pick containers labeled “food safe” or “BPA-free.” These labels help you choose safe products.

Bottle Caps

Bottle caps keep drinks fresh and stop spills. You use them on water bottles, juice, and soda. Injection molding helps companies make lots of caps fast. You get caps that fit tight and twist easily. Most caps use polyethylene or polypropylene. These plastics are strong and safe.

Research shows bottle caps must pass tough safety tests. Factories use machines to check each cap. Caps must fit well and not leak. Some caps have special features. You see tamper-evident rings and easy-open designs.

Safety rules for bottle caps are strict like for containers. Here are some key points:

-

FDA and EFSA rules keep caps safe for food contact.

-

Factories follow GMP to keep caps clean.

-

NSF and ISO 22000 certifications show caps meet safety standards.

-

Only food-grade plastics are used to avoid health risks.

Note: If you see a broken or loose cap, do not use the bottle. Safe caps protect your drinks from germs and spills.

Food packaging helps you keep food fresh and safe. Injection molding gives you containers and caps that work well. These products meet strict safety rules. You can trust them every time you eat or drink.

Defense Equipment

Injection molding helps make defense equipment you can trust. It is used for military gear and strong parts. The military needs parts that work in hard places. These parts must work in bad weather and rough use. Injection molding makes products that are tough and reliable.

Military Gear

Military gear protects you and helps you do your job. Injection molding shapes gear that works in rain, heat, and cold. Binoculars and monocular housings are made this way. These housings keep equipment safe from dust and water. They also protect gear if you drop it.

Many tools now use plastics instead of metal. This makes gear lighter and easier to carry. Lighter gear helps you move faster and feel better. Plastics like PEEK and ULTEM® are strong and last long. You see these in helmets, weapon grips, and cases.

Tip: Lighter gear lets you carry more and move faster on missions.

Military gear made with injection molding lasts longer. These products do not break easily and work in tough places.

Durable Components

Durable components help military vehicles and equipment work well. Injection molding makes parts that are very exact. This helps engines and machines stay safe. Bushings, seals, and thrust washers are made from PEEK. These parts resist heat and pressure and do not fail.

Here are some defense components and their materials:

|

Component Type |

Material Used |

|---|---|

|

Engine Components |

PEEK |

|

Aircraft Interior Components |

ULTEM® (PEI) |

|

Bushings, Seals, Thrust Washers |

PEEK |

|

Various Defense Components |

PPSU, Nylons, PEEK, PC, PAI/PEI, ABS, PMMA, etc. |

Defense equipment uses many kinds of polymers. PPSU, Nylons, PEEK, PC, PAI/PEI, ABS, and PMMA are used for special jobs. Engineers pick the right material for each part. Some parts need to resist heat. Some need to hold heavy loads.

-

PEEK: Light, resists heat, resists pressure.

-

ULTEM®: Stays the same shape, resists heat very well.

Injection molding gives you parts that work the same every time. You get good performance with each use. Research shows plastic parts last longer than metal ones. They resist wear and do not break as much. This helps you trust your gear in the field.

Note: Defense equipment made with injection molding meets strict safety rules. You can trust these parts to work when you need them.

Reports say more military groups want advanced polymers. They want gear that is light, strong, and exact. Injection molding helps by making millions of safe parts.

Electronics Injection Molding

You use electronics every day. Phones, computers, and smart home devices need special plastic parts. The electronics industry uses injection molding to make millions of pieces. These parts fit well and protect the circuits inside. In 2023, companies made over 20 million tons of molded parts. This big number shows how important injection molding is for your devices.

Housings

Housings cover the inside parts of electronics. They keep out dust, water, and bumps. You see housings on laptops, tablets, and game consoles. Companies pick strong plastics like polycarbonate and ABS for these covers. These materials help your devices last longer and look nice.

You get housings made with new technology. Micro-molded parts make devices smaller and lighter. Engineers design housings with tiny details and thin walls. This helps your phone stay slim and easy to hold. You also get better cooling and more room for batteries.

-

Micro-molded housings help make devices smaller.

-

You get products with cool shapes and smooth surfaces.

-

Companies make thousands of housings fast and with less waste.

-

Each housing fits the same, so your device works well.

Tip: When you buy a new device, check the housing. Look for smooth edges and a solid feel. These show good quality and careful design.

Bezels

Bezels go around the screens on electronics. You see them on TVs, monitors, and smartphones. Good bezels make your device look modern and protect the screen. Injection molding lets companies make bezels with sharp corners and thin edges.

Bezels are thinner now than before. This is because molding techniques got better. Engineers use special tools to make bezels with exact sizes. You get more screen space and a better view.

-

Precise molding makes bezels with exact shapes.

-

Thin bezels make devices lighter and easier to use.

-

Good quality means every bezel fits just right.

-

Less waste keeps costs low and helps the planet.

The electronics industry keeps growing. You see new designs and features every year. Injection molding helps companies make parts that are strong, light, and stylish.

Toys and Recreation

Toys bring joy and learning to your life. Injection molding shapes many of your favorite toys. This process lets companies make toys that are safe, colorful, and strong. You see these toys in stores, schools, and homes around the world. The global toy market reached over $100 billion in 2023, and experts expect steady growth as more families look for safe and creative play options.

Action Figures

You find action figures in almost every toy store. These toys let you imagine new worlds and stories. Injection molding helps companies create action figures with bright colors and detailed shapes. You get figures that look like heroes, animals, or even robots. Each figure has smooth edges and strong joints, so you can play without worry.

Makers use non-toxic plastics to keep you safe. They test each material for strength and safety. Many action figures use thermoplastic elastomers, which feel soft but last a long time. Companies also add flame retardants to lower fire risks. This keeps your toys safe at home and in school.

Tip: Always check for safety labels on your toys. These labels show that the toy passed strict tests.

Popular toys made with injection molding include:

-

Action figures and dolls

-

Toy vehicles

-

Collectible figures

-

Playsets and play structures

Toy makers use precise molds to shape every detail. This reduces defects and makes each figure reliable. You get toys that last through many adventures.

Building Blocks

Building blocks help you learn and play at the same time. You can build towers, cars, or even cities. Injection molding makes each block the same size and shape. This means your blocks fit together every time. Companies like LEGO use this process to make millions of blocks each year.

You get blocks in many colors and shapes. Makers use safe plastics that do not break or chip easily. Each batch goes through tests for strength and toxicity. This ensures your blocks are safe for all ages. Some blocks even pass electrical safety checks, so you can use them with lights or motors.

Here are some of the most popular toys made with injection molding:

-

Building blocks (like LEGO)

-

Educational toys

-

Puzzle toys

-

Outdoor toys

A research report from 2023 shows that building blocks remain a top choice for families. These toys help you develop problem-solving skills and creativity. Companies keep improving their designs to meet safety rules and your needs.

|

Safety Feature |

How It Helps You |

|---|---|

|

Non-toxic materials |

Keeps you safe during play |

|

Flame retardant plastics |

Lowers fire risk |

|

Precision mold design |

Reduces sharp edges and defects |

|

Rigorous material testing |

Ensures toys meet safety standards |

You can trust toys made with injection molding. They meet strict safety rules and give you hours of fun and learning.

Injection molding helps many industries make products. This process gives people jobs and helps the economy grow. You get items that are strong, safe, and not expensive. Production is faster and designs look better. Companies use new materials and machines to make things greener and work better.

|

Economic Impact |

Description |

|---|---|

|

Job Creation |

More people find work in their towns. |

|

Economic Contribution |

U.S. factories add over $2.35 trillion to the economy. |

|

Manufacturing Competitiveness |

You get good products made fast. |

|

Innovation and R&D |

Companies create new things for you to use. |

|

Sustainable Practices |

More products use recycled and plant-based materials. |

|

Future Trend |

Description |

|---|---|

|

Sustainable Materials |

Companies pick recycled and biodegradable plastics to cut pollution. |

|

Automation |

Robots and smart sensors help make things quicker and with fewer errors. |

You will see more changes soon. Companies will use better materials and smarter machines. The world market will keep getting bigger. You can expect safer, greener, and cooler products every year.

FAQ

What is injection molding?

Injection molding is a way to make plastic parts. Factories heat plastic until it melts. Then, they push the melted plastic into a mold. The plastic cools down and gets hard. This makes strong shapes that are very exact. Factories use this process to make millions of things every year.

Why do companies choose injection molding?

Companies like injection molding because it is fast. It costs less money and makes less waste. Research shows companies can save up to 30% on costs. This is why many factories use injection molding.

Which industries use injection molding the most?

You see injection molding in many industries. Car makers, hospitals, and electronics companies use it. Packaging companies use it too. In 2024, the market was worth $295 billion.

Are injection-molded products safe for food and medical use?

Yes, these products are safe for food and medicine. Factories follow FDA and ISO rules to keep you safe. Reports say over 90% of medical disposables use this process. This helps keep things clean and safe.

Can you recycle injection-molded plastics?

Many plastics made this way can be recycled. Companies use old plastics to make new things. The Plastics Industry Association says recycling is growing every year.

How does injection molding help the environment?

Injection molding helps the planet by making less waste. Many companies use recycled or plant-based plastics. Studies show this process makes up to 20% less scrap than old ways.

What materials do you use in injection molding?

Factories use plastics like ABS, polycarbonate, and PEEK. Each plastic is good for different jobs. For example, PEEK is used in planes and medical tools. It does not melt or break from chemicals.

How do you know if a product was made with injection molding?

Look for smooth surfaces and sharp details on the product. Strong shapes are another clue. Most toys, phone cases, and food containers are made this way. You can also check the label for more information.

English

English bahasa Indonesia

bahasa Indonesia