Injection molding and overmolding are two fundamental manufacturing processes that have revolutionized the automotive industry. These techniques are essential for producing a wide range of components, from internal cabin parts to under-the-hood enclosures, with high precision and efficiency. The ability to create complex geometries and integrate multiple functions into a single part makes these processes indispensable for modern vehicle design.

The use of injection molded and overmolded parts in vehicles offers significant benefits. They enable weight reduction, which is critical for improving fuel efficiency and extending the range of electric vehicles. They provide incredible design flexibility, allowing for the creation of intricate and aesthetically pleasing components. Furthermore, these processes are cost-efficient for high-volume production, helping manufacturers meet demanding production schedules and control costs. Ultimately, these advanced manufacturing techniques contribute to the overall durability, safety, and performance of today's automobiles.

What is Injection Molding?

Injection molding is a highly versatile and widely used manufacturing process for producing parts by injecting molten material into a mold. It's the go-to method for creating plastic components with high precision, repeatability, and in large volumes.

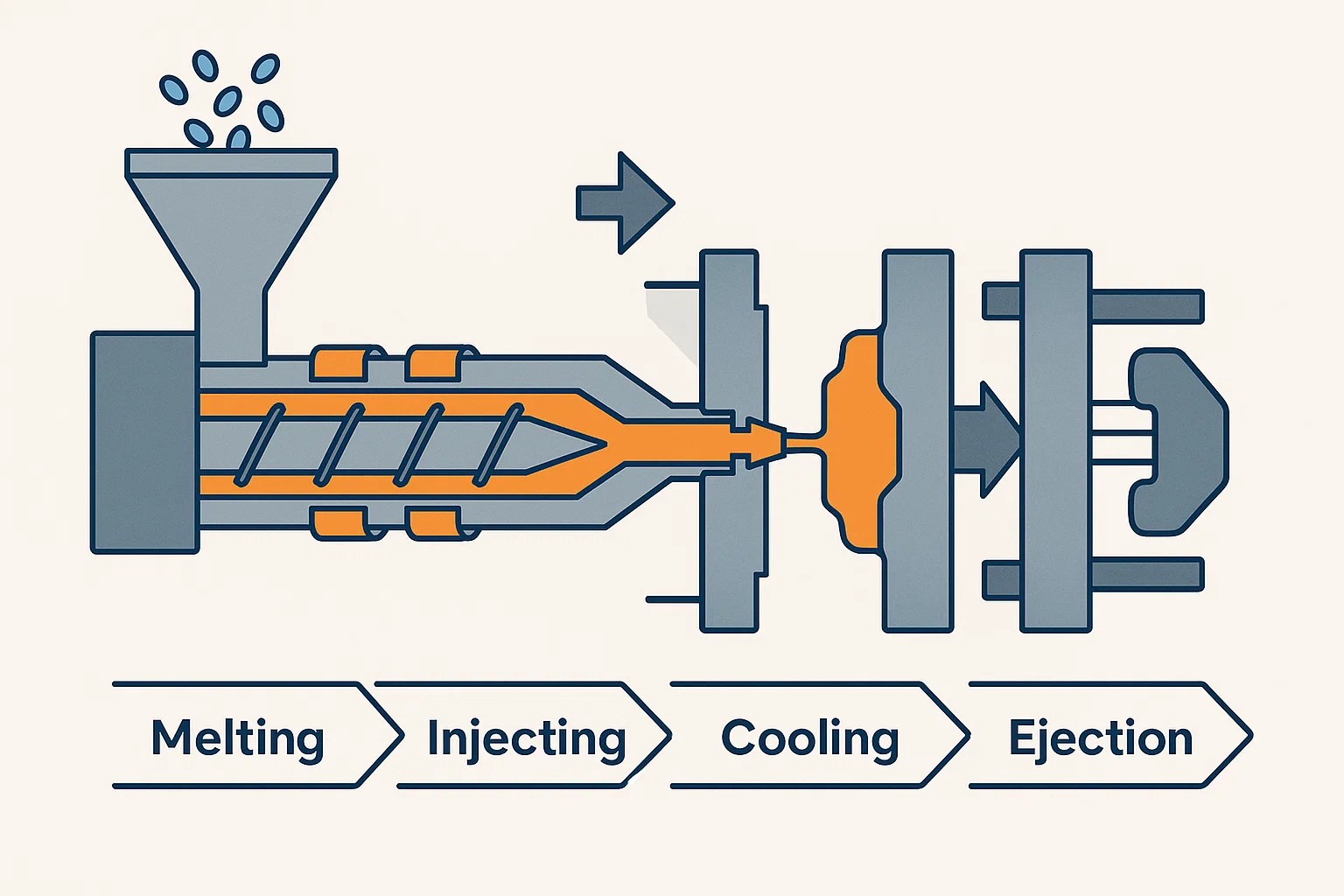

How It Works: Melting, Injecting, Cooling, and Ejection

The process of injection molding follows a precise and cyclical sequence:

-

Material Preparation: Plastic pellets (or other thermoplastic materials) are fed from a hopper into a heated barrel.

-

Melting: Inside the barrel, a reciprocating screw moves the pellets forward while they are heated to a molten state. The screw's rotation and friction also contribute to the heating, ensuring the material is a uniform, viscous fluid.

-

Injection: The molten plastic is then rapidly injected under high pressure into the mold cavity, which is clamped shut. This pressure ensures the material completely fills every intricate detail of the mold.

-

Cooling: Once the cavity is filled, the mold is held at a controlled temperature to allow the plastic to cool and solidify, taking on the shape of the mold.

-

Ejection: After the material has solidified, the mold opens, and the finished part is ejected by a series of ejector pins. The mold then closes, and the cycle repeats.

Types of Injection Molding Techniques

While the basic principle remains the same, several advanced techniques have been developed to meet specific automotive requirements:

-

Gas-Assisted Injection Molding: This technique involves injecting an inert gas (usually nitrogen) into the mold cavity after the plastic has been partially injected. The gas core-outs the thick sections of the part, reducing material usage, minimizing sink marks, and improving dimensional stability. This is particularly useful for parts with thick wall sections like door handles and steering wheel frames.

-

Multi-Component (2K/3K) Injection Molding: This process uses a single machine to inject two or more different materials or colors into the same mold. The mold rotates or shifts to position the first shot for the injection of the second material. This technique is often used for parts with both rigid and flexible sections, such as a car key fob with a hard plastic body and soft rubber buttons.

-

In-Mold Labeling (IML): This process integrates a pre-printed label or decorative film directly into the mold cavity before injection. The molten plastic is injected behind the label, fusing it permanently to the part. This creates a durable, high-quality graphic that is resistant to scratches and fading, perfect for dashboard displays and console panels.

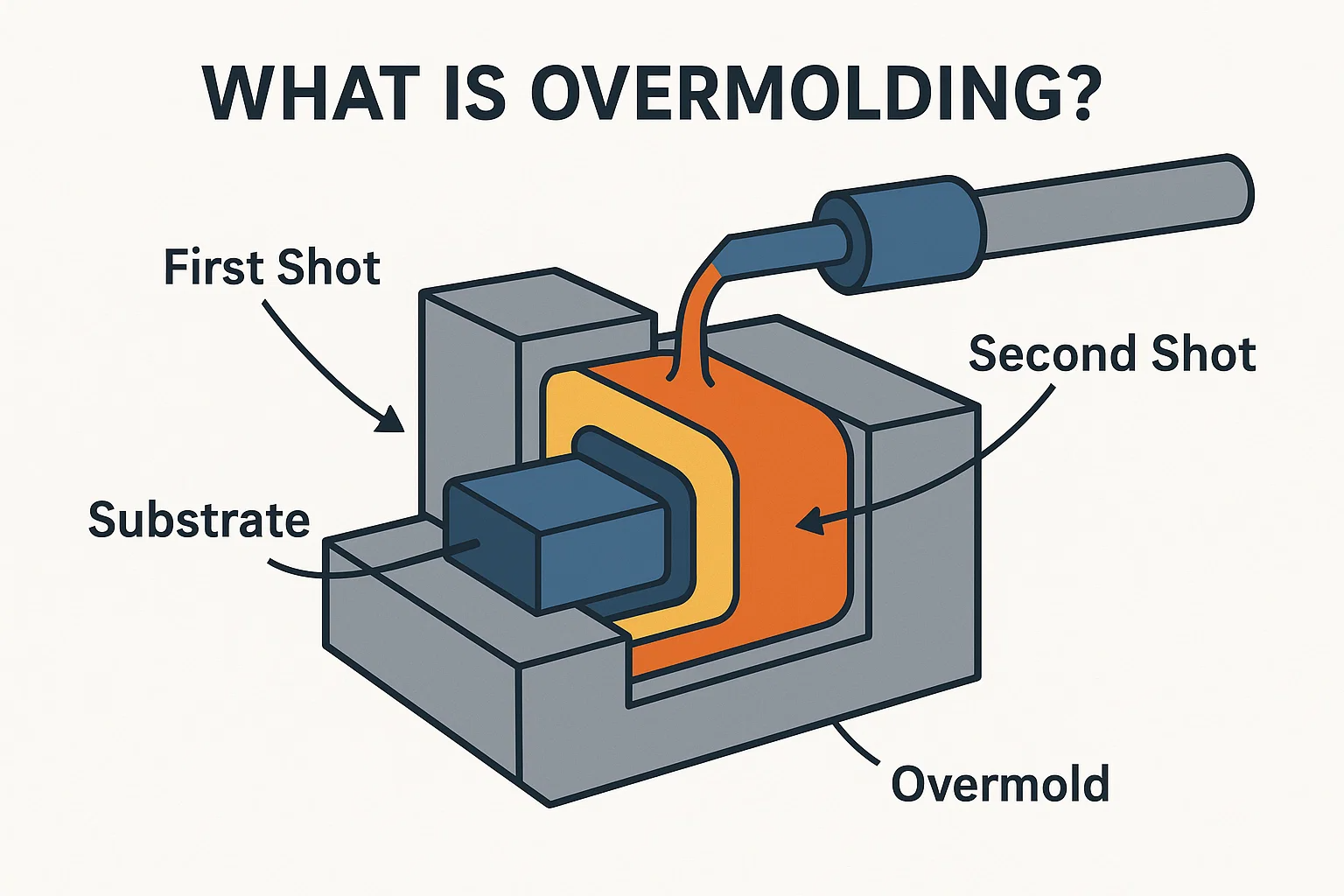

What is Overmolding?

Overmolding is a specialized injection molding process that takes the concept of multi-material parts a step further. It involves molding one material—typically a soft, flexible thermoplastic—over a pre-existing part or substrate, which is usually a rigid plastic or metal. This creates a single, integrated component with the combined properties of both materials.

How It Works: Molding One Material Over Another

The overmolding process builds upon the basic injection molding cycle:

-

First Shot (Substrate): A rigid base component, known as the substrate, is created either through a prior injection molding cycle, a machining process, or as a pre-fabricated metal part.

-

Placement: The finished substrate is then precisely placed into a second mold cavity. This mold is designed with a space around the substrate to form the overmolded material.

-

Second Shot (Overmold): The second material, the overmold material, is injected into the empty space of the second mold.

-

Bonding and Cooling: The molten overmold material flows over the substrate, bonding to it through a combination of mechanical interlocking and chemical adhesion. As it cools and solidifies, the two materials become one permanent component.

Benefits of Overmolding

Overmolding is a powerful technique for integrating multiple functionalities into a single part, which is why it's so valuable in the automotive industry.

-

Improved Grip and Ergonomics: By adding a soft-touch material to a rigid surface, overmolding creates comfortable, non-slip grips for steering wheels, gear shifters, and door handles.

-

Enhanced Aesthetics: This process allows for the creation of multi-colored or multi-textured parts, eliminating the need for painting and enhancing the visual appeal of interior components.

-

Functional Integration: Overmolding is used to create gaskets and seals directly on a rigid housing, providing an integrated, waterproof barrier and eliminating the need for a separate assembly step. It can also be used to insulate electronic components or dampen vibrations.

Difference Between Overmolding and Co-Injection Molding

While both processes create multi-material parts, they do so differently:

-

Overmolding is a sequential two-step process where the second material is molded over a solid, pre-existing part. This is ideal for adding a soft layer to a rigid base.

-

Co-injection Molding (or two-shot molding) is a single, continuous process on one machine. It injects two or more materials into the same mold cavity almost simultaneously, with one material forming the core and the other forming the skin. This technique is often used for parts with a strong, rigid core and a softer, aesthetically pleasing outer layer.

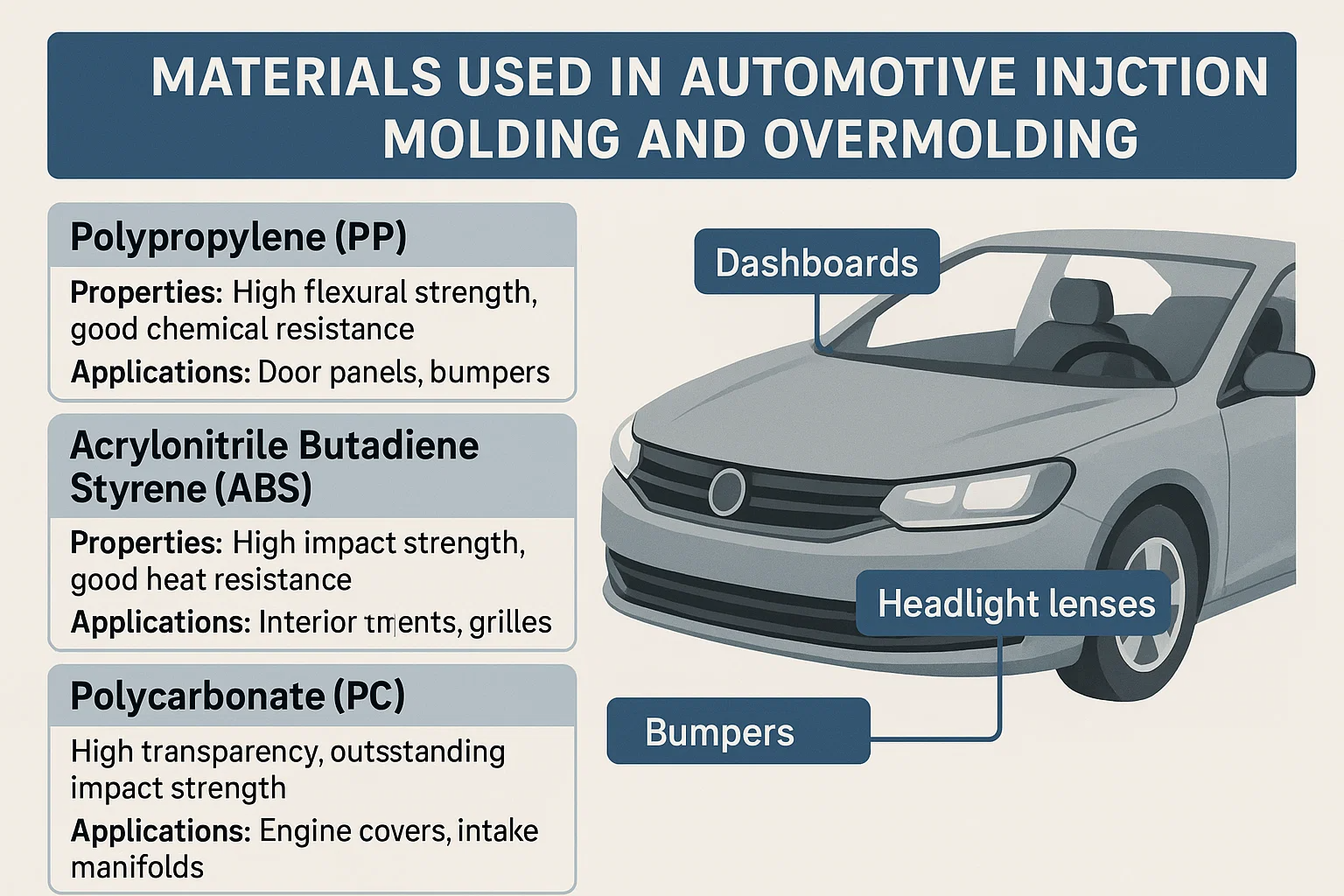

Materials Used in Automotive Injection Molding and Overmolding

The selection of the right material is a critical step in automotive part manufacturing. It dictates the component's performance, durability, weight, and cost. A vast array of plastics and elastomers are used, each with unique properties suited for specific applications.

Common Plastics and Their Automotive Applications

-

Polypropylene (PP): A lightweight, low-cost plastic with excellent chemical resistance, making it ideal for under-the-hood and interior applications.

-

Properties: High flexural strength, good chemical resistance (to acids, bases, and solvents), and fatigue resistance.

-

Applications: Dashboards, door panels, bumpers, fluid reservoirs, and battery cases. Its low density helps with vehicle weight reduction.

-

-

Acrylonitrile Butadiene Styrene (ABS): Known for its balance of toughness, impact resistance, and aesthetic qualities. ABS is a preferred material for interior components.

-

Properties: High impact strength, good heat resistance, and excellent processability for a smooth surface finish.

-

Applications: Interior trim components, dashboard panels, seat belt housings, and grilles. It's often used where a high-quality finish is required.

-

-

Polycarbonate (PC): A transparent, high-strength plastic with exceptional impact resistance. It's a premium material used for safety and aesthetic parts.

-

Properties: High transparency, outstanding impact strength, and good heat resistance.

-

Applications: Headlight lenses, instrument panel displays, and panoramic sunroofs. Its clarity and toughness make it ideal for protecting lighting and displays.

-

-

Polyamide (PA) (Nylon): Known for its high strength, stiffness, and heat resistance, especially when glass-filled. Nylon is a workhorse for under-the-hood and structural components.

-

Properties: High tensile strength, good chemical resistance (to oils and fuels), and excellent thermal stability.

-

Applications: Engine covers, intake manifolds, cooling system components, and various gears and bushings.

-

-

Thermoplastic Polyurethane (TPU): A flexible, soft-touch material that's perfect for overmolding applications where ergonomics and feel are important.

-

Properties: Excellent elasticity, good abrasion resistance, and a soft, rubber-like feel.

-

Applications: Steering wheel grips, gear shift knobs, seals, and wire harnesses. Its ability to be overmolded onto rigid plastics enhances comfort and function.

-

Material Selection Criteria for Different Automotive Parts

Choosing the right material isn't just about a part's function; it involves a complex evaluation of several factors:

-

Performance Requirements: Does the part need to withstand high temperatures, chemical exposure, or impact? This determines the base plastic (e.g., Nylon for heat resistance).

-

Aesthetics and Feel: Is a soft-touch, high-gloss, or textured surface required? This often leads to the use of ABS for smooth finishes or TPU for overmolded grips.

-

Weight Reduction: For every kilogram of weight saved, a car's fuel efficiency improves. This drives the use of lightweight materials like PP over traditional metals.

-

Cost: The cost of the raw material is always a factor in high-volume automotive production. PP and ABS are generally more cost-effective than PC or specialty grades of Nylon.

-

Processing Requirements: The material must be able to be processed efficiently by the chosen molding technique without degradation.

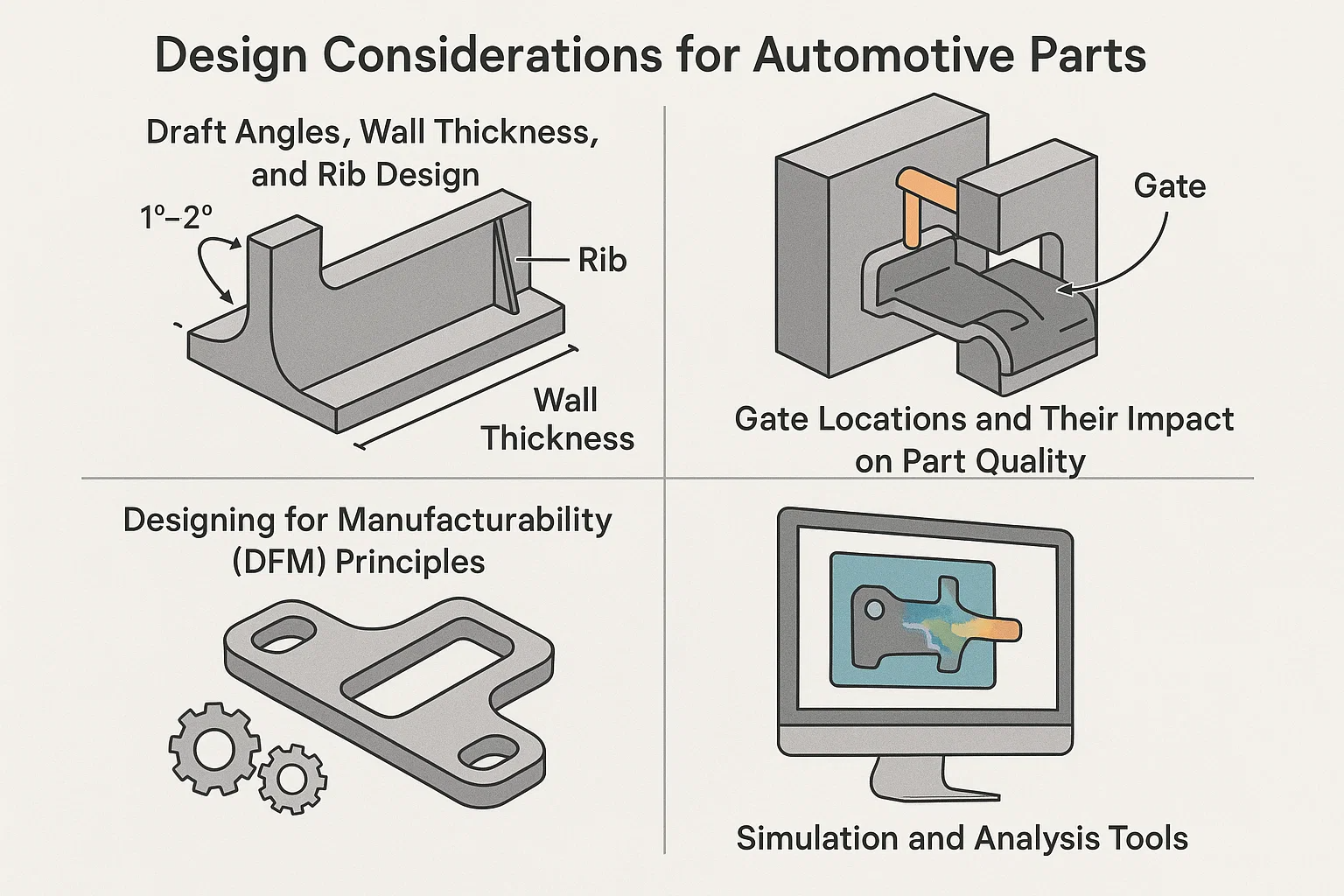

Design Considerations for Automotive Parts

The success of injection molded and overmolded automotive parts hinges on a meticulous design process. A well-designed part is not only functional but also manufacturable, durable, and cost-effective. Adhering to fundamental design principles is crucial to avoid common issues like warping, weak bonds, and cosmetic defects.

1. Draft Angles, Wall Thickness, and Rib Design

-

Draft Angles: These are slight tapers on the vertical walls of a part, making it easier to eject from the mold without damage. A typical draft angle is 1-2 degrees. Without a proper draft, a part can get stuck in the mold, leading to longer cycle times and potential damage to the part or the mold itself.

-

Wall Thickness: Maintaining a consistent wall thickness is one of the most critical rules. This ensures uniform cooling, which prevents warping, sink marks (depressions on the surface), and internal stresses. Abrupt changes in thickness can cause uneven shrinkage, leading to a weak or non-existent bond in overmolded parts.

-

Rib Design: Ribs are thin, supporting walls that add stiffness and strength to a part without increasing its overall wall thickness. They are essential for structural integrity and preventing warping. To avoid sink marks on the cosmetic side, a rib's thickness should be about 50-60% of the wall it supports.

2. Gate Locations and Their Impact on Part Quality

The gate is the point where molten plastic enters the mold cavity. Its location is critical for the flow of material, the final part's appearance, and its mechanical properties.

-

Optimal Flow: A well-placed gate ensures the mold cavity is filled evenly and completely. Incorrect gate placement can lead to incomplete filling (short shots), flow lines, or weld lines (where two flow fronts meet), which are often weak points.

-

Minimizing Defects: For cosmetic parts, the gate should be placed in a non-visible or easily trimmed area to prevent blemishes. In overmolding, the gate for the second shot should be positioned to allow the material to flow smoothly and completely over the substrate without creating excessive pressure that could damage it.

3. Designing for Manufacturability (DFM) Principles

DFM is a proactive approach to product design that aims to optimize all aspects of a product for ease of manufacturing. In the automotive sector, this includes:

-

Part Consolidation: Designing a single, complex part to replace multiple smaller components, which reduces assembly time and costs.

-

Standardization: Using standard features like hole sizes, bosses, and clips that can be easily replicated across different products.

-

Tolerance Analysis: Specifying appropriate tolerances that are tight enough for function but not so tight that they increase manufacturing costs unnecessarily.

4. Simulation and Analysis Tools

Modern design is supported by advanced software. Mold Flow Analysis is a key simulation tool that predicts how molten plastic will flow into the mold. It helps designers identify potential issues like sink marks, warp, and weld lines before a physical mold is ever made, saving significant time and money. Other tools can simulate stress, vibration, and thermal performance to ensure the part meets all durability requirements.

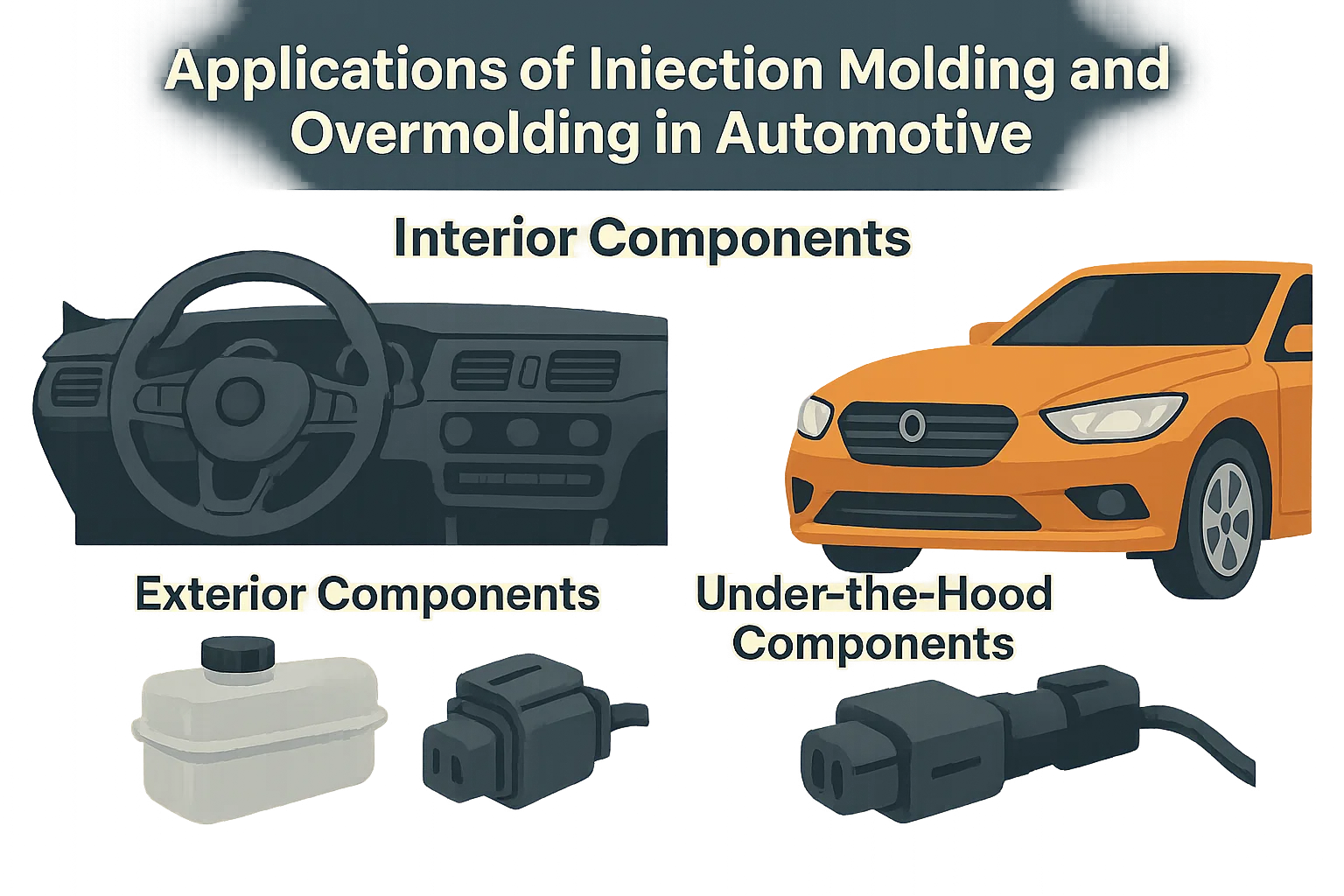

Applications of Injection Molding and Overmolding in Automotive

Injection molding and overmolding are a crucial part of the automotive manufacturing landscape. They allow for the creation of complex, lightweight, and durable components across a vehicle's interior, exterior, and under-the-hood systems.

Interior Components

These parts focus on aesthetics, ergonomics, and safety. Injection molding and overmolding enable the integration of features like soft-touch surfaces, integrated buttons, and complex shapes.

-

Dashboard Components: The main dashboard panel is typically injection molded from PC/ABS, a material known for its dimensional stability and heat resistance. Knobs, buttons, and decorative trim pieces often use overmolding to combine a rigid plastic core with a soft TPU or TPE surface for a better feel and appearance.

-

Door Panels: These are usually injection molded from polypropylene (PP), a lightweight and cost-effective material. Overmolding is used on the armrests and handle grips to add a comfortable, soft-touch layer.

-

Knobs and Buttons: Shift knobs, radio controls, and other interface buttons are perfect candidates for overmolding. A rigid plastic core provides structural integrity, while an outer layer of TPU or TPE offers a comfortable, non-slip grip and a premium feel.

-

Steering Wheel Components: The core of the steering wheel is often a metal insert, but the outer grips can be overmolded with TPU to provide a comfortable, grippy surface.

Exterior Components

Exterior parts demand high durability, weather resistance, and a flawless finish.

-

Bumpers and Grilles: Bumpers are injection molded from a blend of PP and EPDM (ethylene propylene diene monomer), which provides excellent impact resistance and flexibility. Grilles are typically made from ABS or PA (nylon), as these materials can be chrome-plated or painted to a high-quality finish.

-

Mirror Housings: These are commonly injection molded from ABS, chosen for its smooth surface and resistance to impact.

-

Lighting Components: Headlight and taillight lenses are precision injection molded from clear PC or PMMA (polymethyl methacrylate), which offers excellent optical clarity and UV resistance. The light housings themselves are often made from high-temperature resistant PC or ABS.

Under-the-Hood Components

These components must withstand high temperatures, vibrations, and exposure to oils and chemicals.

-

Fluid Reservoirs: Tanks for coolant and windshield washer fluid are injection molded from PP, which is lightweight and resistant to chemical degradation.

-

Connectors and Housings: Automotive electrical connectors and sensor housings are often injection molded from PA (nylon) due to its high strength and thermal resistance. Overmolding is crucial here, as a soft-touch material is often molded around the connector to create a waterproof and dust-proof seal, protecting the internal electronics.

Advantages of Using Injection Molding and Overmolding in Automotive

Injection molding and overmolding have become cornerstone technologies in the automotive industry due to their distinct advantages over traditional manufacturing methods. They enable a synergistic combination of performance, efficiency, and design freedom that is essential for modern vehicle development.

Weight Reduction

One of the most significant advantages is weight reduction. By replacing heavier metal parts with high-strength, lightweight plastics, manufacturers can drastically reduce the overall weight of a vehicle. This directly translates to:

-

Improved Fuel Efficiency: Lighter vehicles require less energy to move, leading to lower fuel consumption for internal combustion engine cars.

-

Extended EV Range: For electric vehicles, a lighter body and chassis mean less energy is needed from the battery to travel the same distance, thus extending the vehicle's range.

Design Flexibility

These processes offer unparalleled design flexibility, allowing engineers to create complex geometries and intricate designs that would be difficult or impossible with traditional methods like stamping or casting.

-

Complex Shapes: Injection molding can produce parts with internal features, varying wall thicknesses, and complex curves in a single shot.

-

Part Consolidation: Overmolding, in particular, enables the integration of multiple functions into a single part. For example, a single overmolded part can serve as a structural component, a seal, and a soft-touch grip, thereby reducing the number of parts needed and simplifying the assembly process.

Cost Efficiency

Injection molding and overmolding are highly cost-efficient for mass production, a key requirement of the automotive industry.

-

Low Cost Per Part: While the initial tooling costs for molds can be high, the cost per part drops dramatically in high-volume production runs.

-

Reduced Assembly Costs: The ability to consolidate multiple parts into one, especially with overmolding, significantly reduces labor and time spent on assembly. This streamlines the manufacturing line and lowers overall production costs.

-

Minimal Waste: The processes generate very little material waste, as any excess plastic (runners and sprues) can often be reground and reused.

Durability and Performance

Plastic automotive components are engineered to meet strict performance requirements.

-

Corrosion and Chemical Resistance: Unlike metal, plastic does not rust, and certain grades are highly resistant to chemicals, oils, and fuels found under the hood.

-

Impact Resistance: Materials like ABS and PC are specifically chosen for their high impact strength, providing critical protection for both interior and exterior components.

-

Vibration and Noise Dampening: Overmolding with soft materials like TPE can effectively dampen vibrations and reduce noise, leading to a quieter and more comfortable ride.

Quality Control and Testing

Given the critical role that automotive components play in vehicle safety and performance, rigorous quality control is non-negotiable. Manufacturers must adhere to strict standards to ensure every part meets specified requirements for dimensional accuracy, material properties, and durability.

Importance of Quality Control in Automotive Part Manufacturing

The automotive industry operates under a zero-defect mentality. A single faulty component can lead to vehicle recalls, significant financial losses, and, most importantly, put driver and passenger safety at risk. Effective quality control is integrated throughout the entire manufacturing process, from material selection to final part inspection. It ensures that every part is reliable, consistent, and performs as designed under various operating conditions.

Testing Methods: Dimensional Accuracy, Strength, and Durability

A variety of sophisticated testing methods are employed to validate the quality of injection molded and overmolded parts:

-

Dimensional Accuracy:

-

CMM (Coordinate Measuring Machine): This highly precise tool uses a probe to measure the physical dimensions of a part, ensuring it matches the original CAD model with a very tight tolerance.

-

Optical Scanners: Non-contact scanners capture millions of data points to create a 3D model of the part, which is then compared against the digital blueprint to check for deviations.

-

-

Strength and Durability:

-

Tensile and Impact Testing: These tests measure a material's ability to withstand pulling forces and sudden impacts, respectively. They are crucial for parts like bumpers and interior trim.

-

Peel and Shear Testing: For overmolded parts, these tests are essential to evaluate the bond strength between the two materials. A "peel test" measures the force required to separate the overmold from the substrate, while a "shear test" measures the force required to slide one material off the other.

-

-

Environmental and Chemical Resistance:

-

Thermal Cycling: Parts are subjected to repeated cycles of extreme hot and cold temperatures to simulate real-world conditions and check for warping or bond failure.

-

Chemical Exposure: Components are tested with common automotive fluids like oils, brake fluid, and cleaning agents to ensure they do not degrade over time.

-

Standards and Certifications: IATF 16949, etc.

To ensure consistent quality across the supply chain, the automotive industry relies on specific standards and certifications.

-

IATF 16949: This is the global quality management standard for the automotive industry. Certification demonstrates a supplier's commitment to continuous improvement, defect prevention, and reduction of variation and waste.

-

ISO 9001: While not automotive-specific, this broader quality management standard is often a prerequisite for IATF 16949 and demonstrates a company's commitment to quality processes.

Future Trends in Automotive Injection Molding and Overmolding

The automotive industry is in a constant state of evolution, driven by the shift toward electric vehicles, autonomous driving, and sustainable manufacturing. Injection molding and overmolding technologies are adapting to these changes, with several key trends shaping their future.

1. Use of Recycled and Bio-Based Materials

As environmental regulations become stricter, there is a growing demand for sustainable materials.

-

Recycled Plastics: Manufacturers are increasingly using recycled plastics, such as recycled PP and PET, to produce non-structural components. This reduces waste and lowers the carbon footprint of production.

-

Bio-Based Materials: The industry is exploring materials derived from renewable sources like cornstarch or cellulose. These bio-based plastics offer a greener alternative to traditional petroleum-based polymers and are particularly appealing for interior trim and components.

2. Advancements in Molding Technologies

New technologies are making the molding process more efficient, precise, and capable of producing more complex parts.

-

High-Pressure Injection Molding: This technique allows for the creation of thinner-walled parts without sacrificing strength, further contributing to vehicle weight reduction.

-

Digitalization and Automation: The integration of robotics and AI-driven systems is leading to fully automated injection molding cells. These systems can self-adjust process parameters, perform real-time quality checks, and optimize cycle times, reducing human error and boosting efficiency.

-

Micro-Injection Molding: This technology can produce incredibly small and precise plastic components, which are essential for the miniaturization of electronic sensors and connectors in modern cars.

3. Integration of Smart Technologies in Molded Parts

The future of automotive parts lies in their ability to be "smart" and interactive.

-

In-Mold Electronics (IME): This groundbreaking technology allows electronic circuits and sensors to be molded directly into a plastic part. This is enabling the creation of seamless, integrated dashboard controls, lighting systems, and touch-sensitive surfaces. IME reduces assembly time, lowers weight, and opens up new possibilities for interior design.

-

Sensors and Actuators: Miniaturized sensors for temperature, pressure, and position can be overmolded into various components, providing real-time data for a vehicle's control systems. This is crucial for the development of advanced driver-assistance systems (ADAS) and autonomous vehicles.

Case Studies: Successful Automotive Applications

The real power of injection molding and overmolding is best demonstrated through successful real-world applications. These case studies highlight how these technologies solve complex design and manufacturing challenges, delivering superior performance, aesthetics, and cost-efficiency.

1. Overmolded Automotive Connectors

Challenge: Automotive connectors, especially those in the engine bay, must be completely sealed against moisture, dust, and chemicals. Traditionally, this was achieved by using a separate rubber gasket, which added a manual assembly step and was a potential point of failure.

Solution: A dual-material overmolding process was implemented. A rigid, heat-resistant plastic, such as Polyamide (PA) or PBT, was used to form the main body of the connector. A soft, chemical-resistant Thermoplastic Elastomer (TPE) or LSR (Liquid Silicone Rubber) was then overmolded directly onto the connector's housing to form a permanent, integrated seal.

Benefits Achieved:

-

Enhanced Durability: The integrated seal provides superior protection against environmental factors, preventing shorts and corrosion.

-

Cost Reduction: By eliminating the need for a separate gasket and the manual assembly step, manufacturing costs were significantly reduced.

-

Improved Reliability: The permanent chemical and mechanical bond between the two materials ensures the seal will not fail or dislodge under vibration or temperature changes.

2. Interior Door Panels

Challenge: Modern door panels require a combination of a rigid, structural frame and a soft-touch, aesthetically pleasing surface. Creating this with multiple parts and adhesives was complex, heavy, and expensive.

Solution: An injection molding approach using different materials was used. The main door panel structure was injection molded from lightweight Polypropylene (PP). For areas requiring a premium feel, such as the armrest, a dedicated soft-touch material was either overmolded onto the PP frame or the entire panel was covered in a fabric or leather-like film during the molding process (In-Mold Labeling).

Benefits Achieved:

-

Weight Reduction: The use of lightweight PP helped reduce the overall vehicle weight, contributing to better fuel efficiency.

-

Aesthetic Quality: The process enabled a seamless, high-quality finish with no visible seams or gaps between the rigid and soft sections.

-

Part Consolidation: By integrating the soft-touch surface directly into the panel, the number of parts and assembly time were reduced.

3. High-Performance Headlight Lenses

Challenge: Headlight lenses need to be crystal clear to maximize light output, extremely durable to resist impacts and scratches, and able to withstand UV radiation without yellowing. Glass is too heavy and prone to shattering.

Solution: High-precision injection molding with Polycarbonate (PC) was used. This process allows for the creation of complex, optically clear lens shapes with intricate internal prisms and light guides in a single shot. A hard, UV-resistant coating is then applied to the molded lens to protect it from damage and environmental degradation.

Benefits Achieved:

-

Optical Clarity: Precision molding techniques ensure a flawless finish, maximizing light transmission and beam control.

-

Safety and Durability: PC offers exceptional impact resistance, protecting the headlight assembly from road debris.

-

Design Freedom: Injection molding allows for unique and complex lens designs that contribute to the vehicle's aesthetic identity.

English

English Indonesia

Indonesia